Casting process for directional control valve

A directional control valve and casting process technology, applied in manufacturing tools, casting molding equipment, casting molds, etc., to avoid overheating, ensure appearance quality, and ensure product dimensional accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The invention provides a manufacturing process of a directional control valve, which mainly includes the following steps:

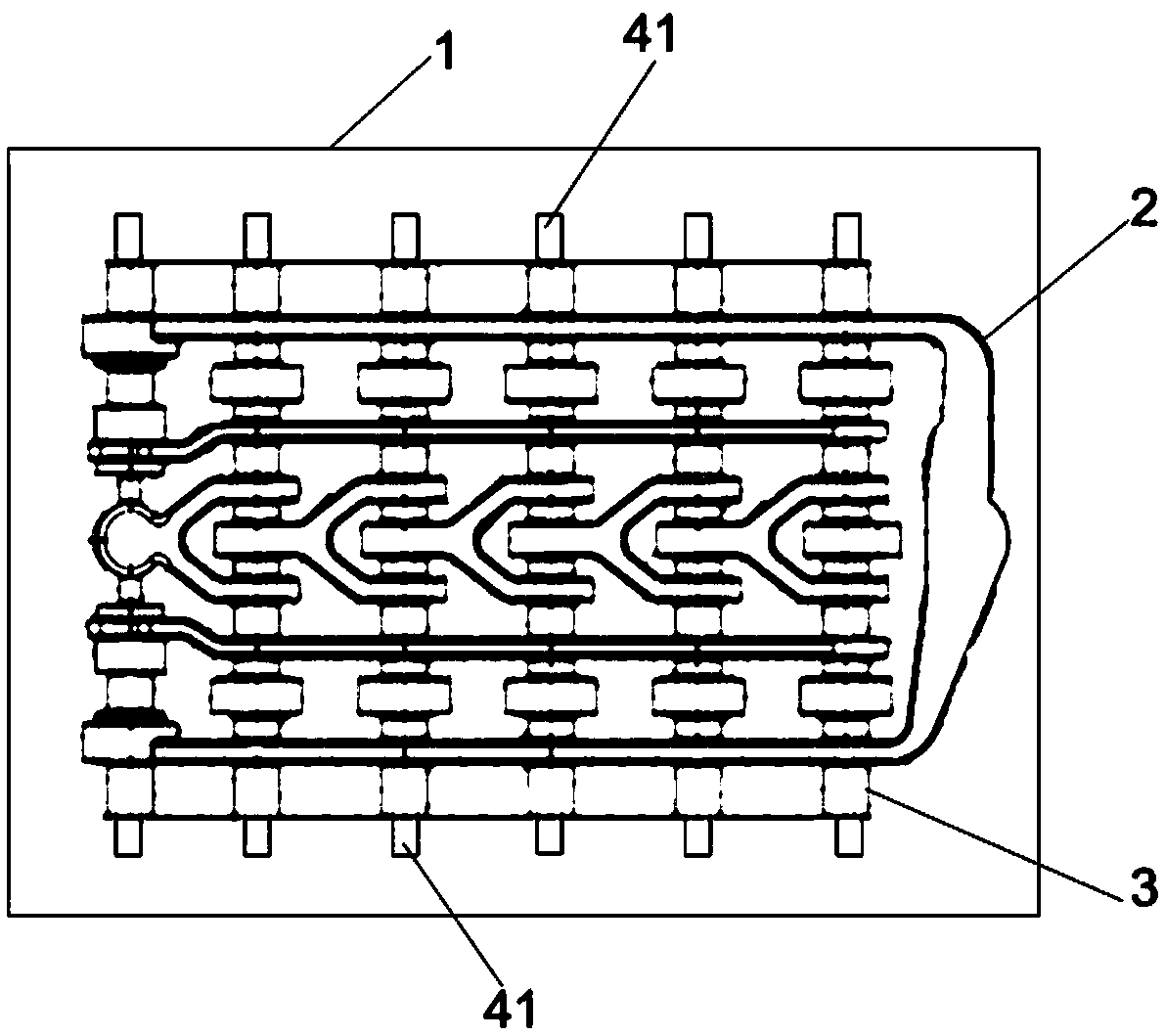

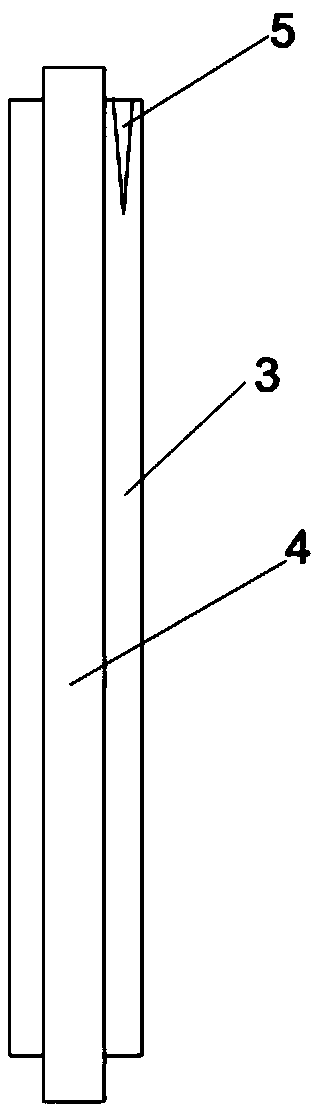

[0036] S1, molding process (as shown in the figure and figure 2 As shown): make a shell 1, and set a gate with a height of 8 mm and a length of 30 mm on the side of the shell 1; use resin sand molding to make a clay core 2, and set a core bone 4 in the clay core 2 and the ventilation needle 5, and the ventilation needle 5 is set away from the mandrel 4, and the mandrel 4 is made of steel pipe; the mud core 2 is polished after being made, and the two sides of the sand core 2 after polishing The core bone protruding part 41 is provided at the end; the mud core 2 is placed horizontally in the shell 1, and the core bone protruding part 41 is overlapped with the inside of the shell 1; the specific connection structure As follows: the top of the shell 1 is provided with a thermal insulation riser, the shell 1 includes an upper shell and a lower shell, ...

Embodiment 2

[0041] The invention provides a manufacturing process of a directional control valve, which mainly includes the following steps:

[0042] S1, molding process (as shown in the figure and figure 2 As shown): make a shell 1, and set a gate with a height of 8 mm and a length of 30 mm on the side of the shell 1; use resin sand molding to make a clay core 2, and set a core bone 4 in the clay core 2 and the ventilation needle 5, and the ventilation needle 5 is set away from the mandrel 4, and the mandrel 4 is made of steel pipe; the mud core 2 is polished after being made, and the two sides of the sand core 2 after polishing The core bone protruding part 41 is provided at the end; the mud core 2 is placed horizontally in the shell 1, and the core bone protruding part 41 is overlapped with the inside of the shell 1; the specific connection structure As follows: the top of the shell 1 is provided with a thermal insulation riser, the shell 1 includes an upper shell and a lower shell, ...

Embodiment 3

[0047] The invention provides a manufacturing process of a directional control valve, which mainly includes the following steps:

[0048] S1, molding process (as shown in the figure and figure 2 As shown): make a shell 1, and set a gate with a height of 8 mm and a length of 30 mm on the side of the shell 1; use resin sand molding to make a clay core 2, and set a core bone 4 in the clay core 2 and the ventilation needle 5, and the ventilation needle 5 is set away from the mandrel 4, and the mandrel 4 is made of steel pipe; the mud core 2 is polished after being made, and the two sides of the sand core 2 after polishing The core bone protruding part 41 is provided at the end; the mud core 2 is placed horizontally in the shell 1, and the core bone protruding part 41 is overlapped with the inside of the shell 1; the specific connection structure As follows: the top of the shell 1 is provided with a thermal insulation riser, the shell 1 includes an upper shell and a lower shell, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com