Vertical vacuum crystallization device

A vacuum crystallization, vertical technology, applied in the general layout of the crystallization device, solution crystallization, evaporation separation crystallization, etc., can solve the problems of affecting the growth of other crystals, poor mixing degree of slurry, and easy scaling of cooling pipes, etc. Achieve the effects of increasing evaporation intensity, adjusting production load, and reducing the probability of collision, fragmentation and nucleation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to have a further understanding of the purpose, structure, features, and functions of the present invention, the following detailed descriptions are provided in conjunction with the embodiments.

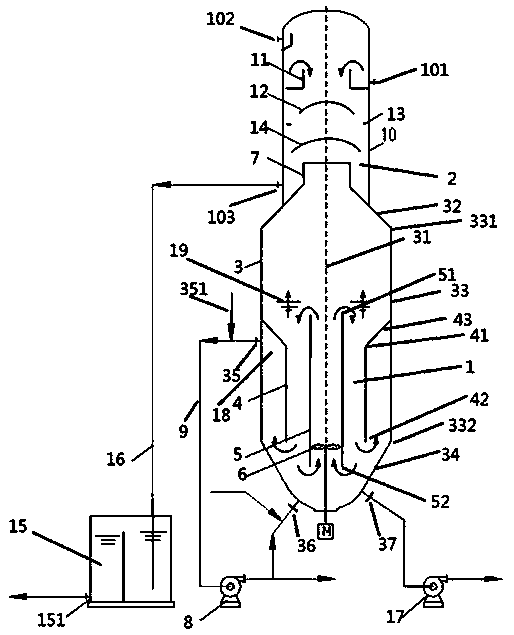

[0034] see figure 1 , figure 1 It is a schematic diagram of the overall structure of a vertical vacuum crystallization device of the present invention, as figure 1 As shown, the vertical vacuum crystallization device according to an embodiment of the present invention includes a crystallization part 1 and a condensation part 2 .

[0035]The crystallization section 1 includes a crystallization section cylinder body 3, an outer guide cylinder 4, a central guide cylinder 5, a bottom agitator 6, a secondary steam ascending cylinder 7, a circulation pump 8, an inner circulation channel and an outer circulation channel.

[0036] The crystallization section barrel 3 is an axisymmetric structure with a central axis 31, comprising successively connected truncated conical upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com