Multifunctional Motor Bearing Sealing Structure

A technology of motor bearings and sealing structures, which is applied in the direction of casings/covers/supports, electromechanical devices, electrical components, etc., can solve problems such as single structure and function, low component utilization, grease suction leakage, etc., to avoid environmental pollution Effects of pollution and resource saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

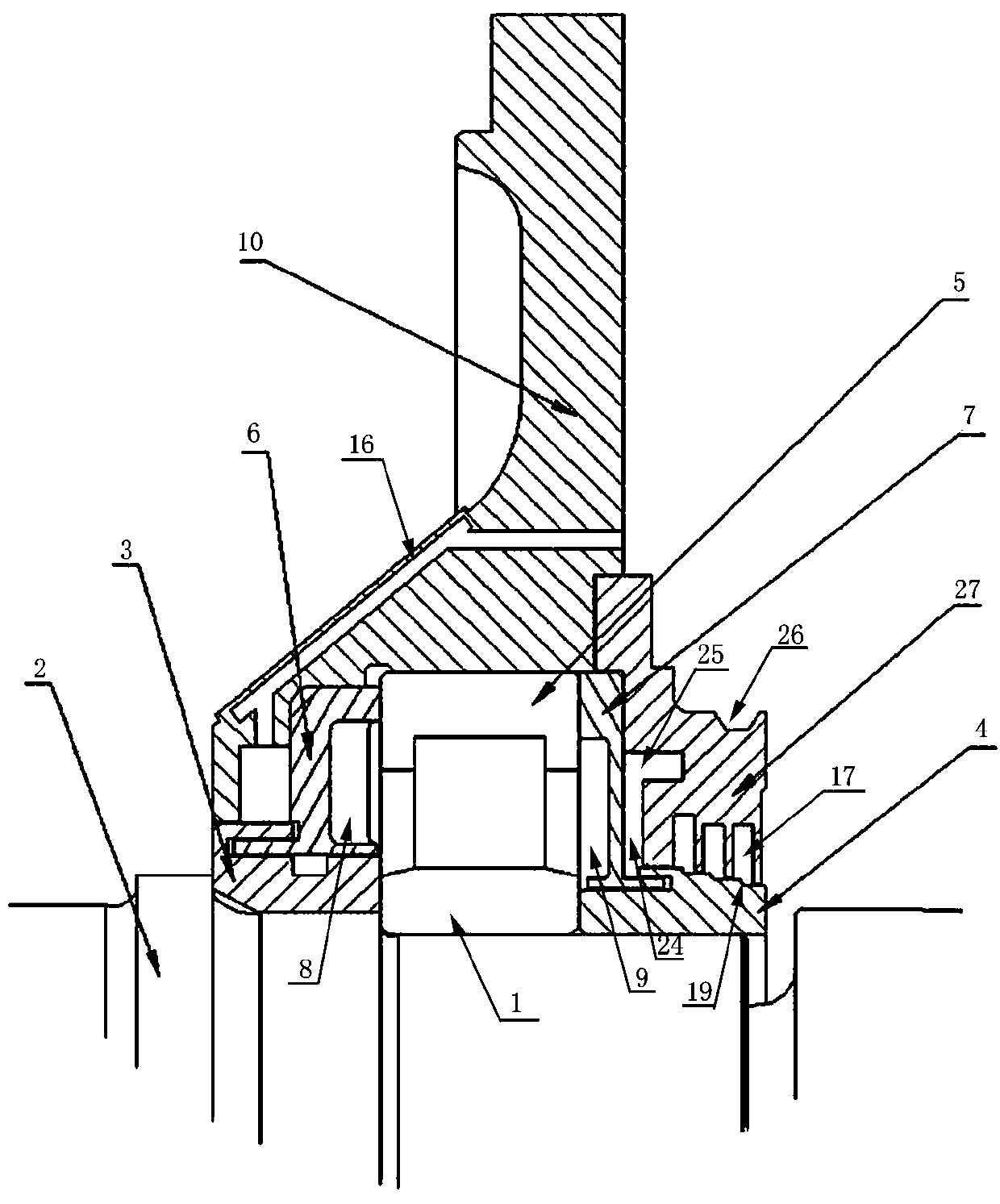

[0017] refer to Figure 1 to Figure 5, the multi-functional motor bearing sealing structure of the present invention includes a shaft sleeve 3 and an outer seal ring 4 which abut against the inner end surface of the bearing inner ring 1 and the outer end surface of the bearing inner ring 1 respectively and are fixed on the rotating shaft 2, the shaft sleeve 3 and the outer sealing ring 4 The outer seal ring 4 axially positions the bearing inner ring 1; it also includes an inner seal ring 6 that abuts on the inner end surface of the bearing outer ring 5 and is labyrinthically sealed with the shaft sleeve 3, and abuts on the outer end surface of the bearing outer ring 5 and is in contact with the outer end surface of the bearing outer ring 5. The outer seal ring 4 is a labyrinth-sealed bearing cover 7, the inner seal ring 6 and the bearing cover 7 are provided with annular recesses facing the bearing to form the inner bearing chamber 8 and the outer bearing chamber 9 respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com