Cooling bearings, motors and other rotating heat generating components

A technology for heat-generating components and bearings, which is applied in the direction of bearing components, bearing cooling, electric components, etc., and can solve problems such as the reduction of thermal conductivity and heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] There are many possible implementations of the present invention, and there are too many to explain here. Some preferred embodiments are described below. These are descriptions of the embodiments of the present invention, rather than descriptions of the present invention. The present invention is not limited to the details described here, but is described by the general terms of the claims.

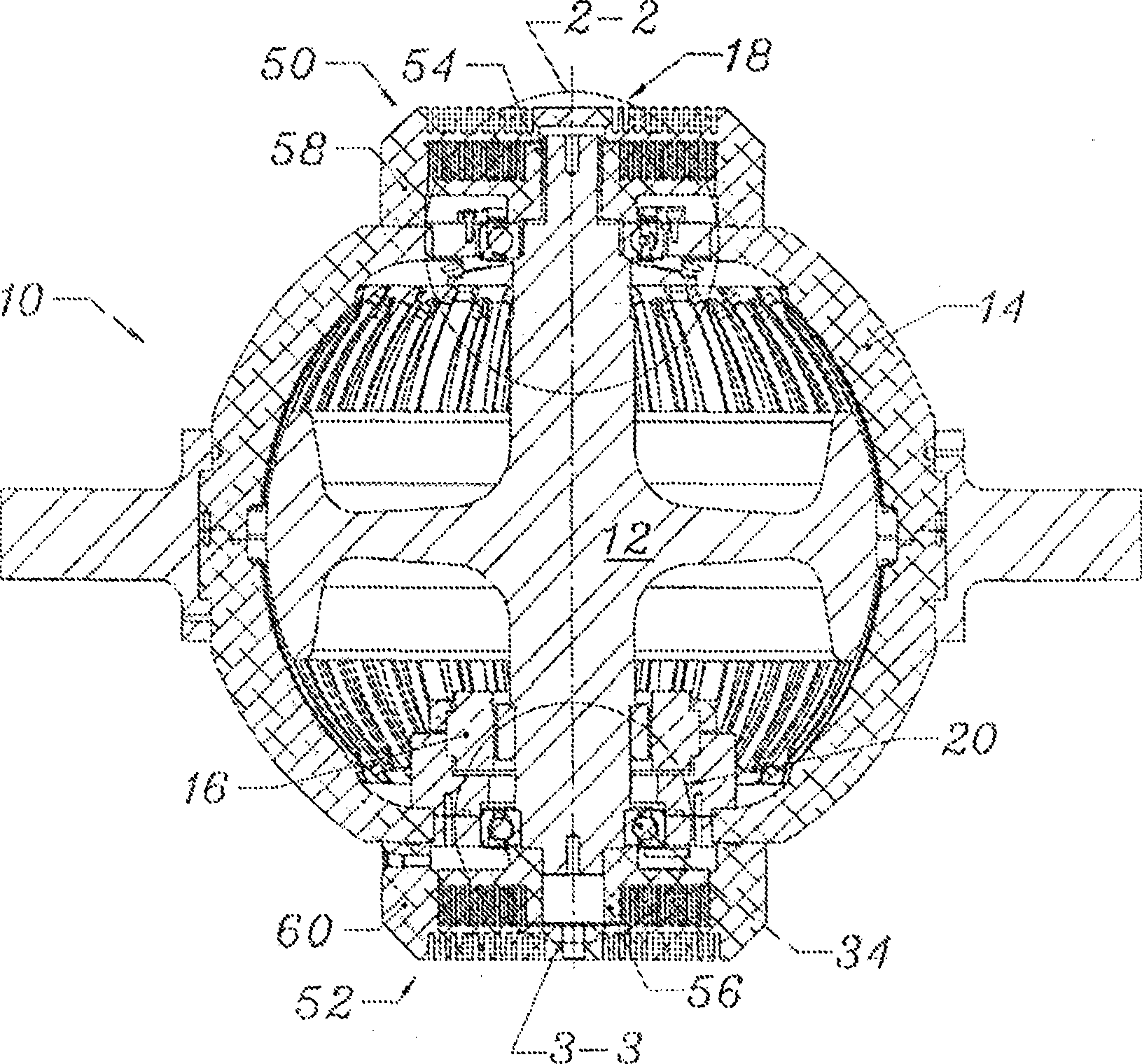

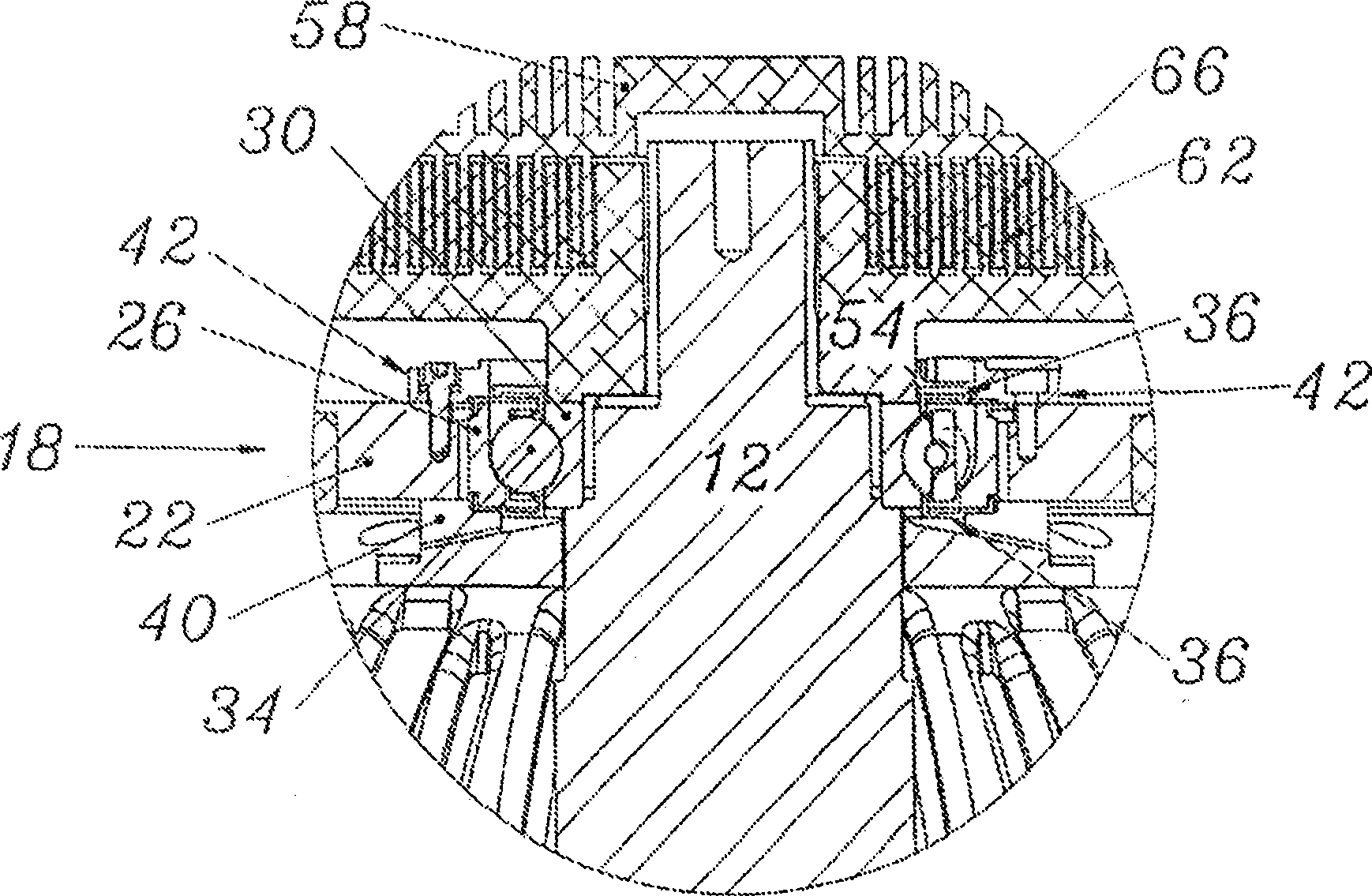

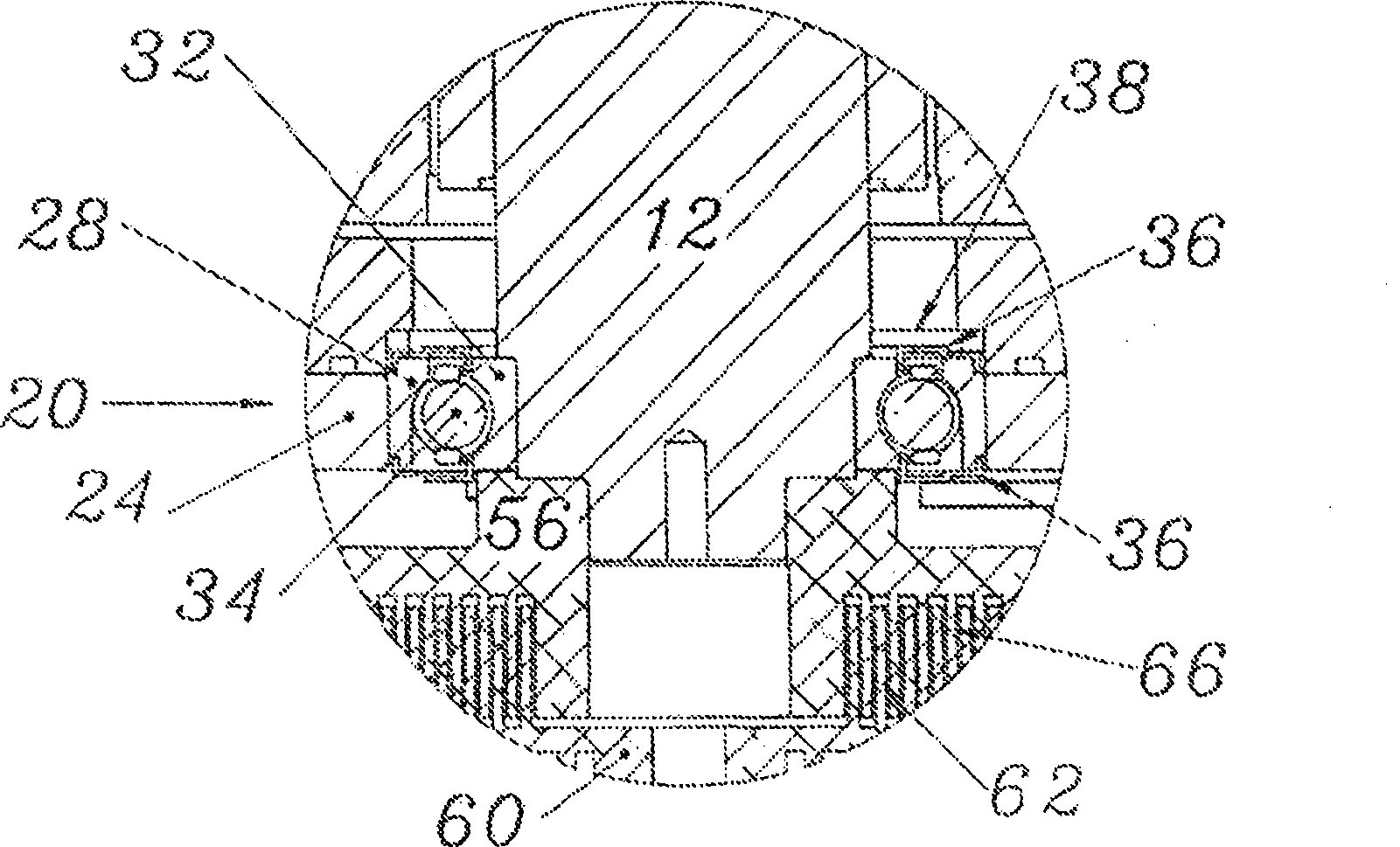

[0041] figure 1 A gyroscope roll stabilizer 10 representing a ship (of the type described in U.S. Patent No. 6,973,847, which is incorporated herein by reference). The steel flywheel 12 rotates in an aluminum housing 14, which is evacuated to a pressure lower than the surrounding pressure and may include a gas with a lower density than the surroundings (such as helium or hydrogen) in order to reduce friction on the rotating flywheel . A motor (a frameless and brushless DC motor) integrally made inside the housing drives a flywheel supported by the upper bearing assembly 18 and the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com