Rotor punching plate adapting to high-speed rotation

A technology of rotor punching and high-speed rotation, applied in the direction of magnetic circuit rotating parts, electrical components, electromechanical devices, etc., can solve problems such as magnetic bridge damage, achieve smooth contours, ensure magnetic flux leakage, and improve molding rates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The following is further described in detail through specific implementation methods:

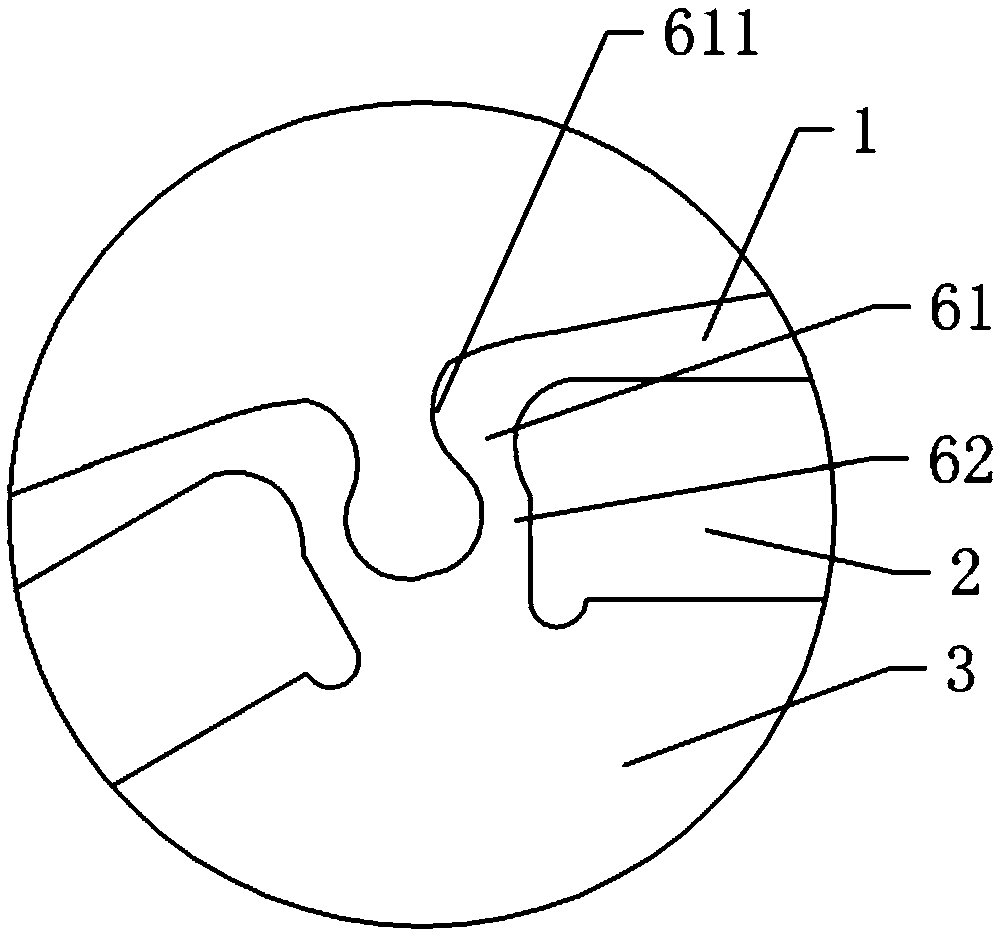

[0012] The reference signs in the drawings of the description include: cover plate 1 , magnetic steel placement cavity 2 , punch body 3 , weight reduction hole 4 , connection hole 5 , reinforcement section 61 , raised portion 611 , and straight section 62 .

[0013] The embodiment is basically as attached figure 1 and figure 2 As shown: a rotor punching plate adapted to high-speed rotation, including a punching plate body 3, and a connecting hole 5 with a keyway is arranged in the middle of the punching body 3 along the axial direction. The punch body 3 is also provided with 12 weight-reducing holes 4 , and all the weight-reducing holes 4 are distributed in an annular array with the axis of the punch body 3 as the central axis. The edge of the punching body 3 is provided with 12 bar-shaped magnetic steel placement cavities 2, and all the magnetic steel placement cavities 2 are arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com