Built-in permanent magnet synchronous motor used for high-speed electric spindle

A permanent magnet synchronous motor, high-speed motorized spindle technology, applied in synchronous motors with static armatures and rotating magnets, magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc. Difficulty and other problems to achieve the effect of not losing magnetism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will now be further described in conjunction with the embodiments and accompanying drawings:

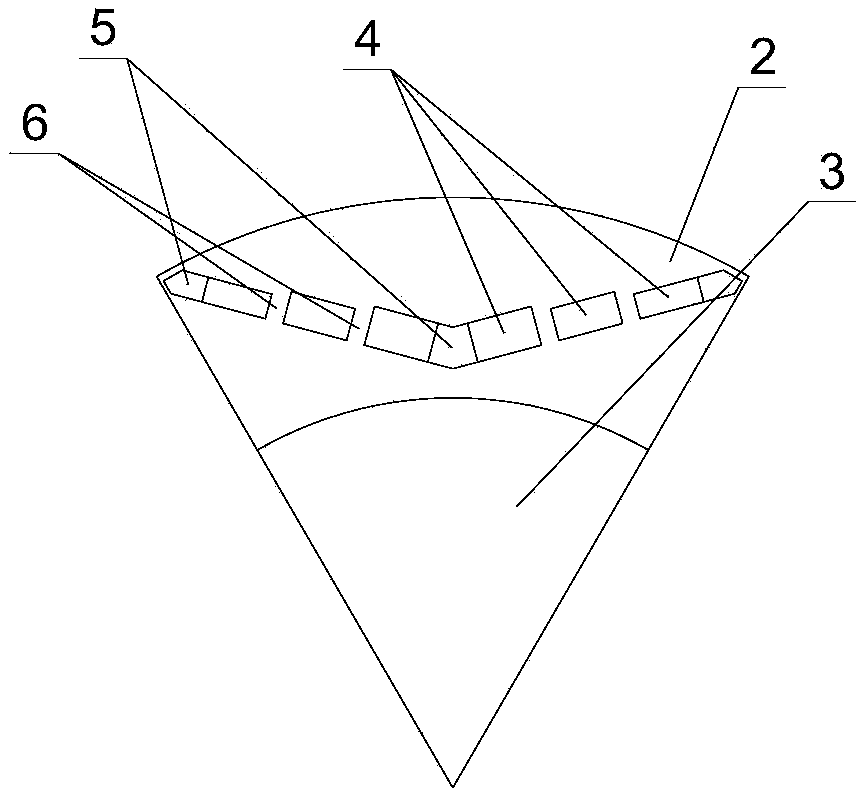

[0017] The technical solution adopted in this embodiment is: in the rotor core of the built-in permanent magnet synchronous motor, radially magnetized V-shaped segmented magnets are evenly inlaid along the circumferential direction, so that the motor weaker can be increased during the operation of the constant power section. The ability of magnetic speed-up reduces torque ripple to a certain extent, and it is not easy to cause the loss of magnetism of the permanent magnet of the motor. In addition, the radial thicknesses of the segmented magnets under one pole are not equal, and the thickness of the segmented magnets near the middle of the magnetic pole under one magnetic pole is greater than the thickness of the segmented magnets on both sides, so that the air-gap magnetic density can be as close to sinusoidal as possible. The distribution can also reduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com