Rotor of asynchronous starting permanent magnet motor and asynchronous starting permanent magnet motor using rotor

An asynchronous starting, permanent magnet motor technology, applied in starting devices, synchronous motors with static armatures and rotating magnets, and electric components, etc., can solve the problems of reducing the performance of permanent magnet motors, reducing starting torque, etc. The effect of high starting torque, improved starting torque, and high pull-in synchronization capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

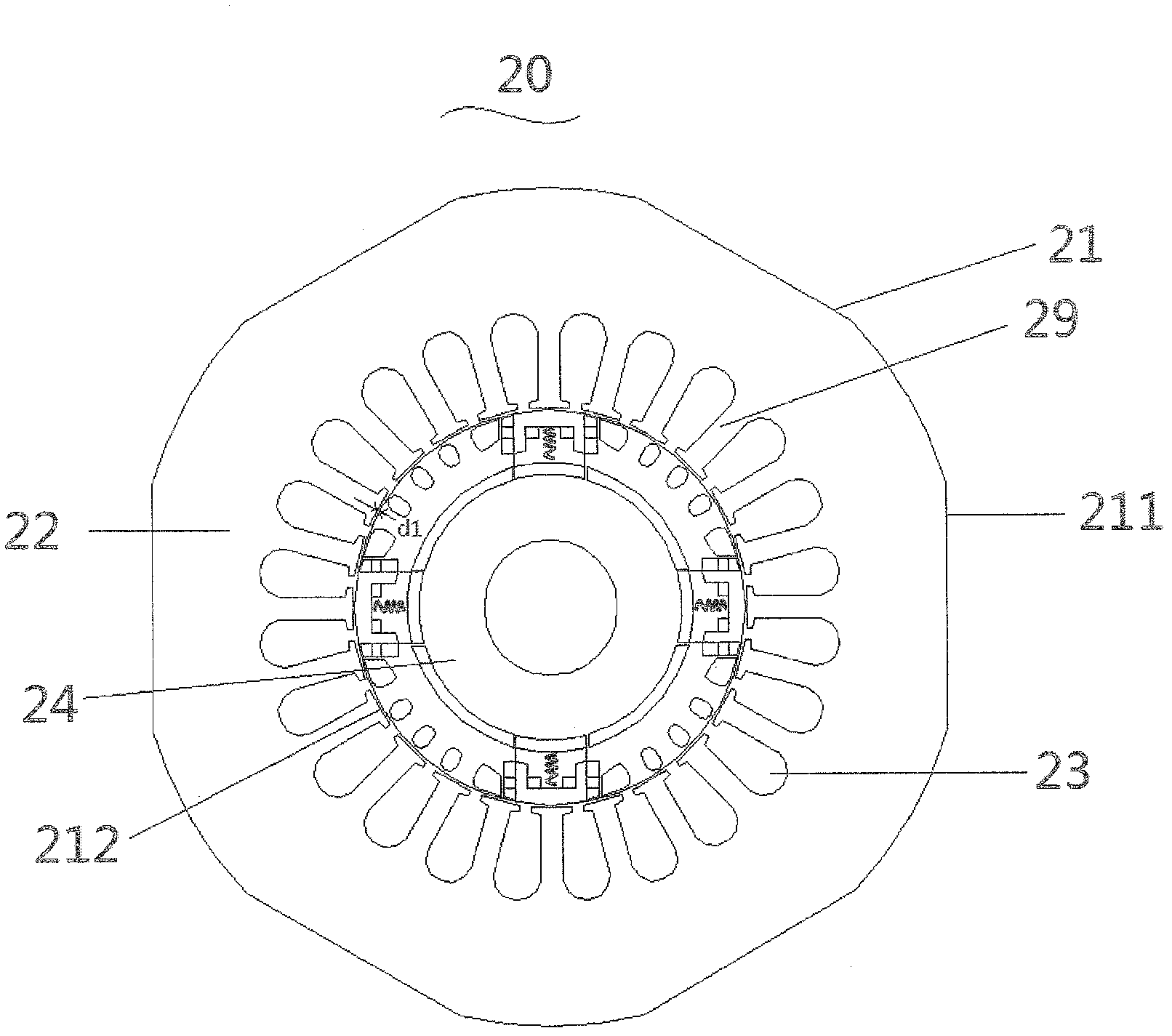

[0037] refer to figure 1 , shows the asynchronous start permanent magnet motor 20 according to the first embodiment of the present invention. The asynchronous start permanent magnet motor 20 includes a stator 21 and a rotor 24 , the rotor 24 is rotatably arranged in the stator 21 and is spaced from the stator 21 by a distance. Specifically, the rotor 24 is disposed in a cylindrical cavity inside the stator 21 . Preferably, said rotor 24 is arranged concentrically in said cylindrical cavity. The stator 21 is spaced apart from the rotor 24 by a distance d1.

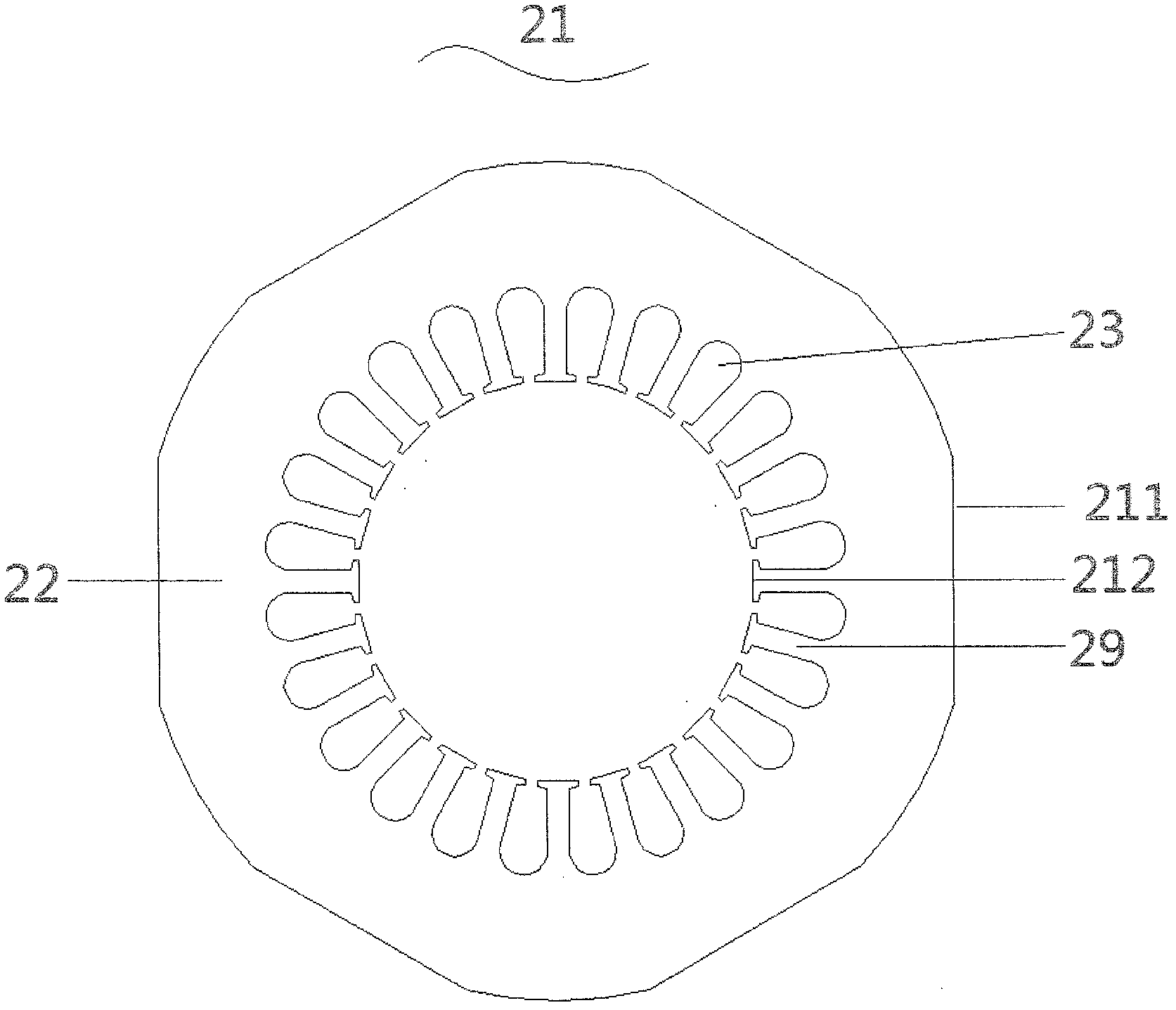

[0038] see figure 2 , the stator 21 includes a cylindrical stator core 22, a plurality of stator teeth 29 extending inward along the radial direction of the stator 21, stator slots 23 distributed between the plurality of stator teeth 29, and Coils (not shown) are wound around the stator teeth 29 to generate a rotating magnetic field. Since the stator 21 is cylindrical, the stator 21 has an outer circumference 211 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com