Lead storage battery pole plate curing-drying process

A plate curing and drying process technology, applied in the direction of lead-acid battery electrodes, etc., can solve the problems of oxygen difficult to enter the plate, long curing time, inconsistent curing effect, etc., to avoid energy loss, improve efficiency, and shorten drying time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

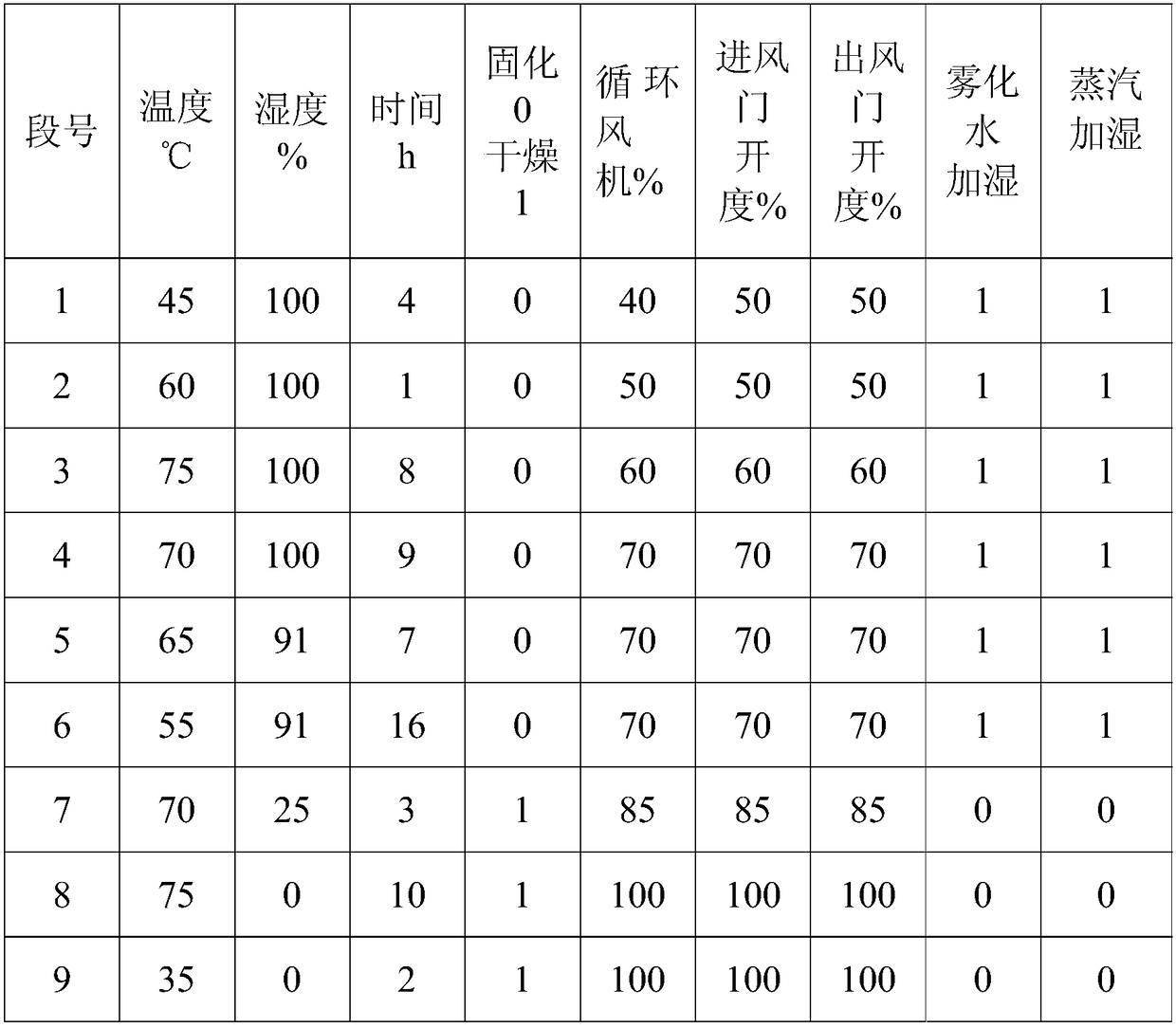

Method used

Image

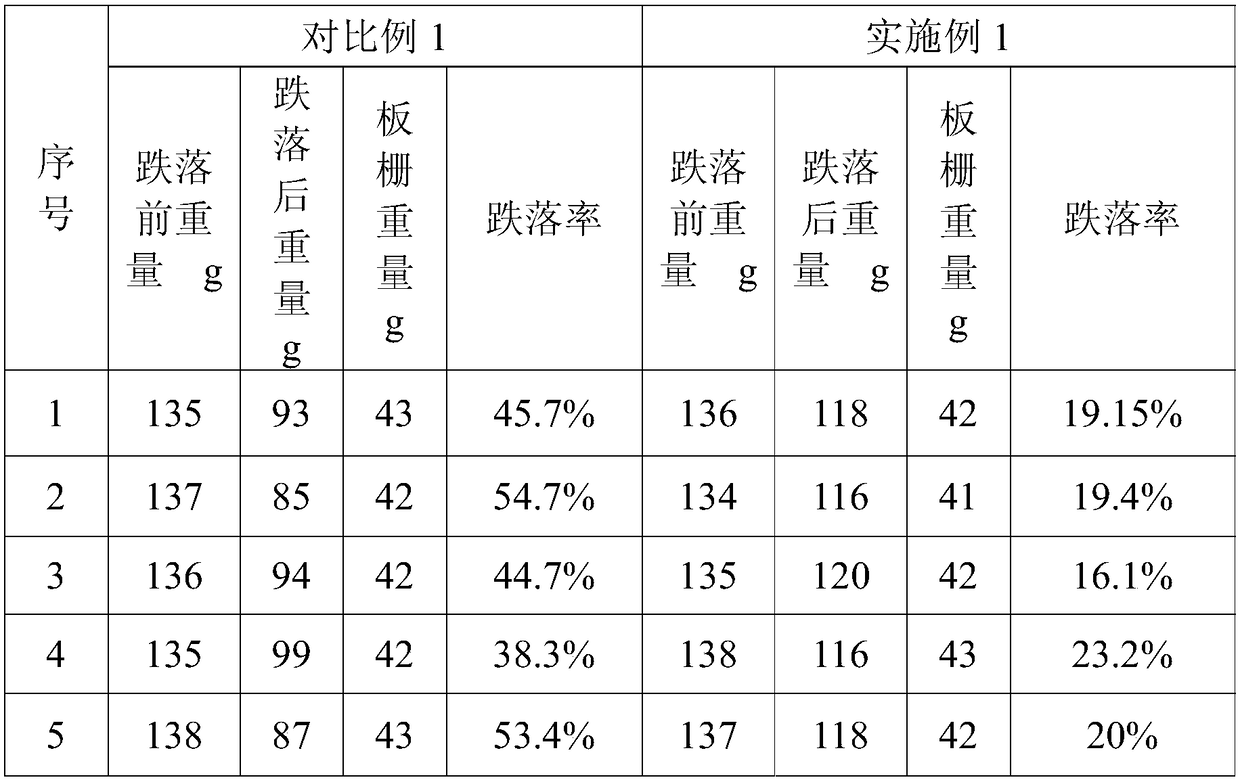

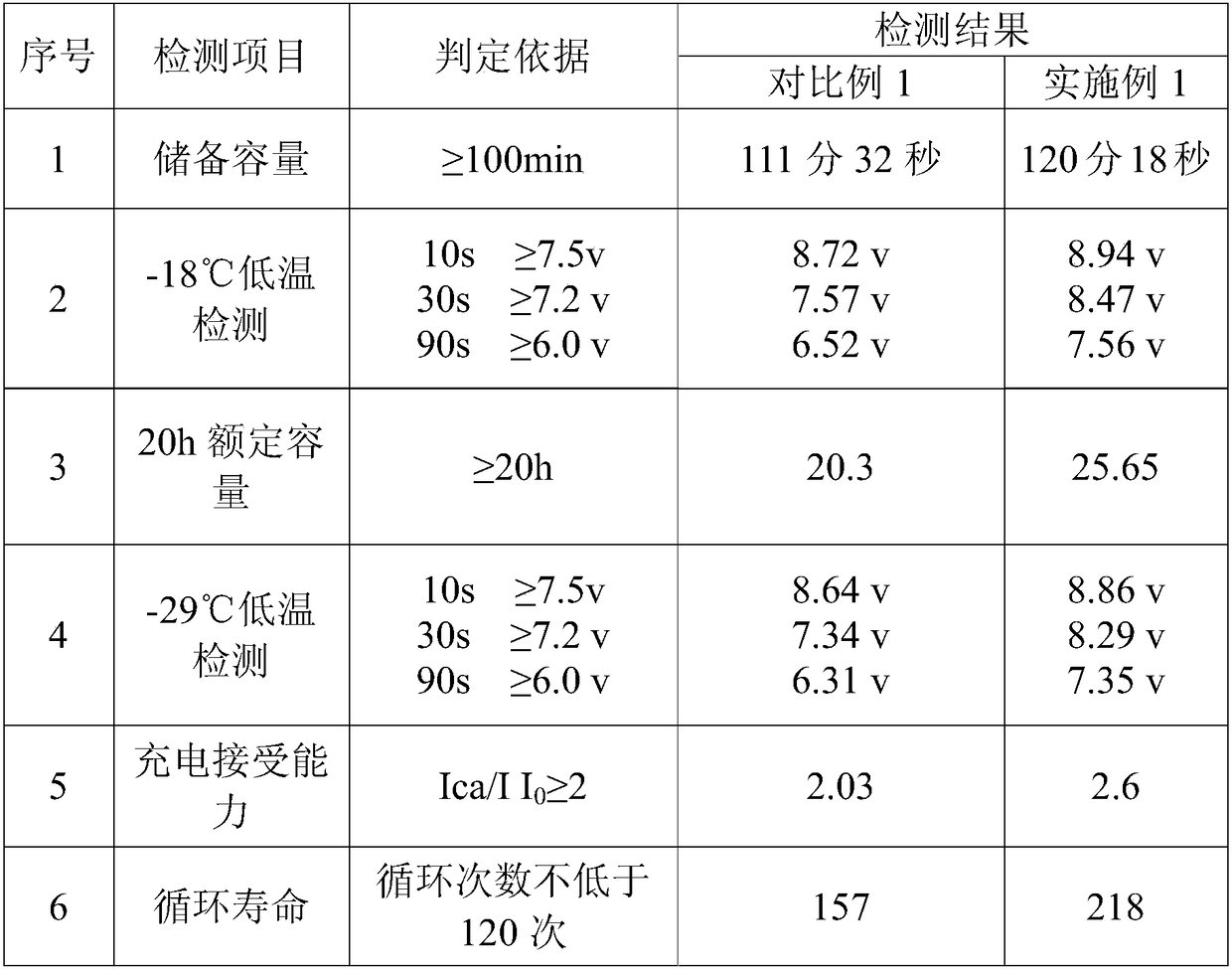

Examples

Embodiment 1

[0044] Taking the 6-QW-80 battery as an example, the curing and drying process of the lead battery plate includes:

[0045] 1. Prepare the mixed solution for humidifying water mist required for the operation of the curing room. The concentration of hydrogen peroxide in the mixed solution is about 75g / L.

[0046] 2. During the period when the polar plate enters the curing room, the temperature in the curing room is kept at 55°C, and the humidity is kept at 98Rh%. After entering the curing room, close the hatch;

[0047] 3. In the first stage of curing, turn on the temperature adjustment system, turn on the negative pressure fan and pump the low pressure to a pressure of 0.05Mpa for 15 to 30 minutes, keep the temperature for 15 minutes, keep the temperature at 55°C, and the humidity at 80Rh%;

[0048]4. In the second stage of curing, turn on the ozone manufacturing equipment, and introduce ozone-containing air with an ozone concentration of 15mg / L into the kiln until the pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com