Method for determining shot peening strengthening optimum parameter of 1Cr12Ni2WMoVNb martensite stainless steel gas turbine blade

A technology for gas turbine blades and martensitic stainless steel, applied in multi-objective optimization, geometric CAD, design optimization/simulation, etc., can solve problems such as unspecified optimal parameters of shot peening, and improve high-cycle fatigue life and fatigue service life and the effect of ensuring the performance of the unit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

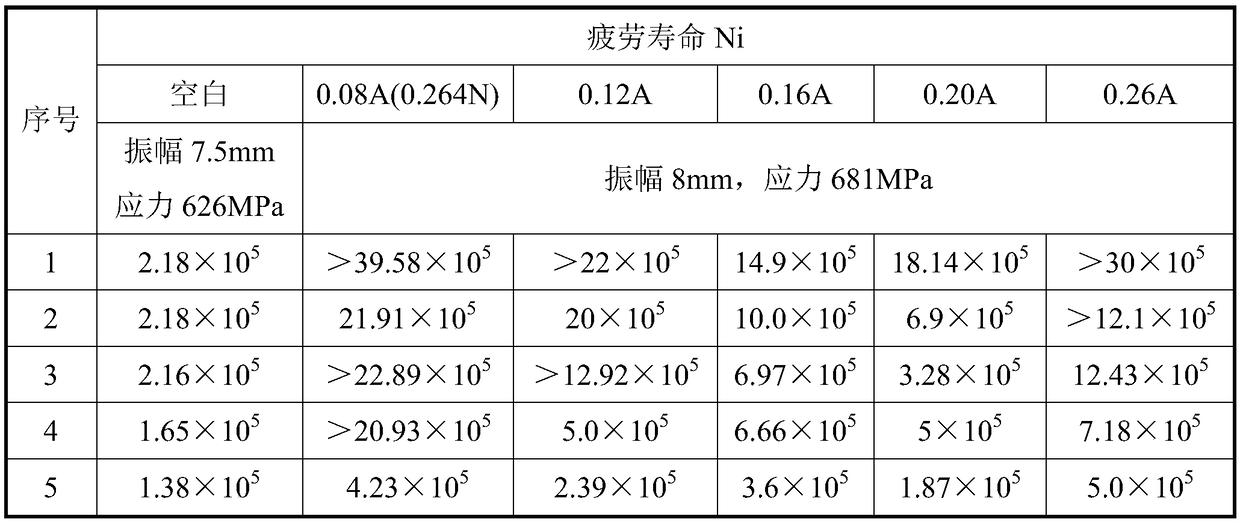

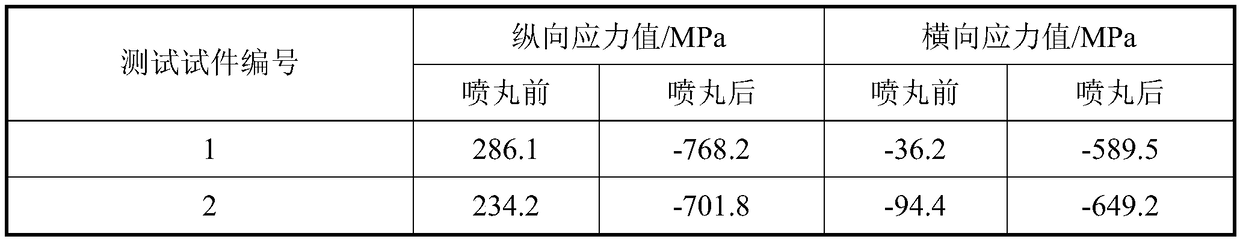

[0014] Through a large number of experimental studies, the optimal parameters for shot peening of 1Cr12Ni2WMoVNb stainless steel gas turbine blade products are found from the perspective of the surface state (roughness, residual stress, etc.) The formed residual stress field and so on. The shot peening shot is S110, the shot peening is carried out according to HB / Z26, and the fatigue test is designed according to HB / Z 5277, including the structural design, production and fatigue test process of the test piece.

[0015] Through the test data that meets the sample statistical standards, the optimal shot peening parameters are obtained, and the corresponding surface state is obtained at the same time. The specific process is as follows:

[0016] 1. Test piece structure design

[0017] The specimen structure is designed according to HB / Z 5277, and the specimen structure can most effectively represent the stress state of the blade, and the thickness of the specimen is (3±0.2)mm. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface compressive stress | aaaaa | aaaaa |

| Surface compressive stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com