Flooded evaporator

A flooded evaporator and evaporator technology, which is applied in the direction of evaporator/condenser, refrigeration and liquefaction, refrigeration components, etc., can solve the problems of compressor return gas with liquid, and achieve the solution of return gas with liquid and lifting separation Function, the effect of improving the stability of working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

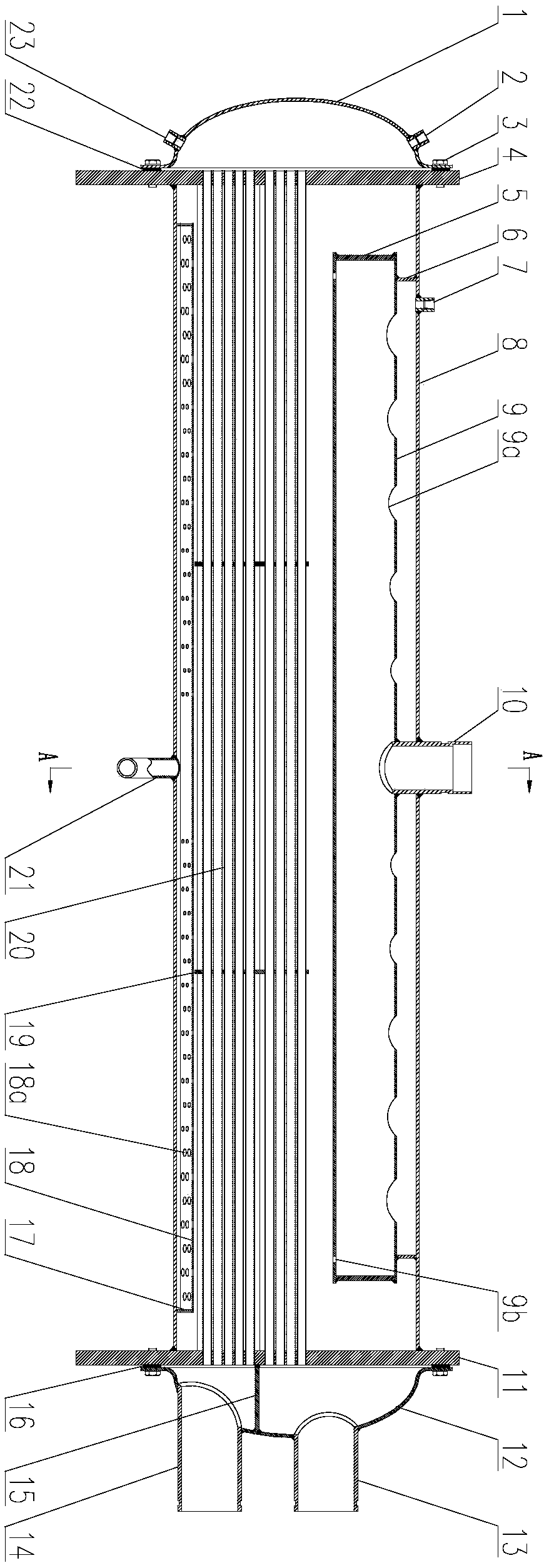

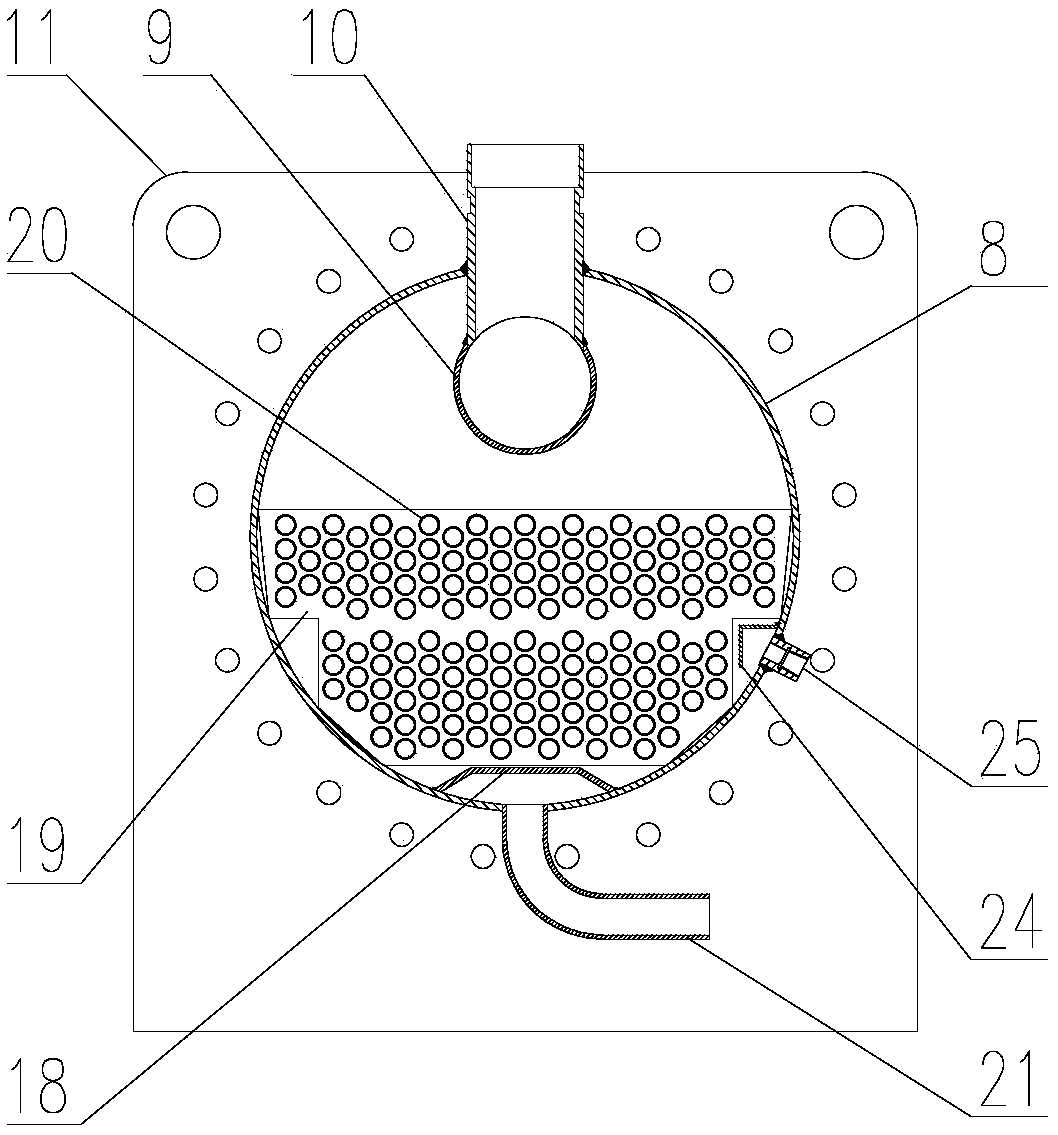

[0023] Embodiment: A flooded evaporator, including a flooded evaporator body, the evaporator body includes a shell 8, a first tube sheet 4 and a second tube sheet 11 closing both ends of the shell 8, and bolts 3 The first end cover 1 and the second end cover 12 installed outside the first tube sheet 4 and the second tube sheet 11. The top of the housing 8 is also provided with a safety valve seat 7 , the side of the housing 8 is provided with an oil return port 25 , and an oil stabilizing plate 24 is provided at a position opposite the inner chamber of the housing 8 to the oil return port 25 . The top of the first end cover 1 is provided with an exhaust valve seat 2 , and the bottom is provided with a drain valve seat 23 . The joint position of the first end cover 1 and the first tube sheet 4 is provided with a first gasket 22, the joint position of the second end cover 12 and the second tube sheet 11 is provided with a second gasket 16, the first gasket 22 and the second The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com