Phosphogypsum light-weight sheet material prepared from barium dreg and preparation method thereof

A technology of phosphogypsum and phosphogypsum dihydrate, which is applied in the field of building materials, can solve the problems of occupying a large amount of land resources, there is no method for large-scale utilization of phosphogypsum waste, and harmful ion soil environmental pollution, etc., and achieves adjustable and optimized bulk density. Hardened body microstructure, the effect of improving overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

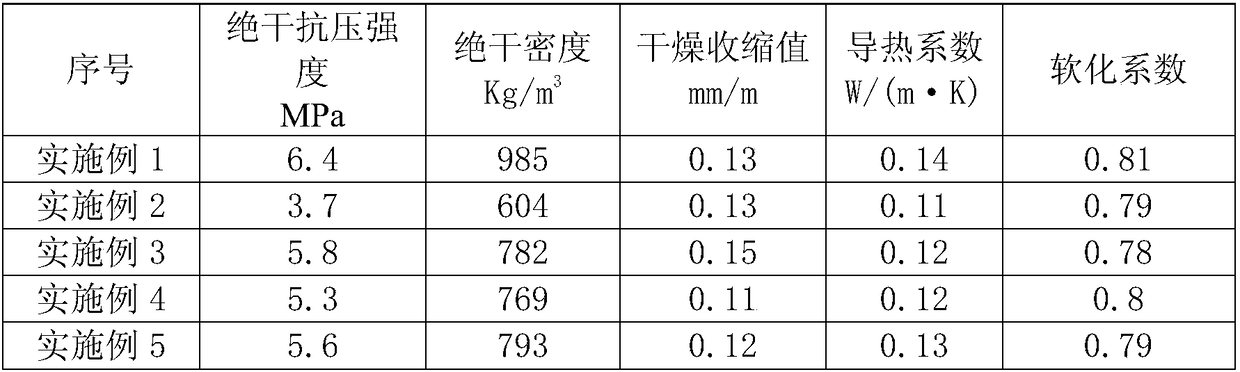

Examples

Embodiment 1

[0027] Provide a kind of phosphogypsum lightweight board prepared by barium slag, its component and weight content include:

[0028] 10 parts of barium slag, 4 parts of dihydrate phosphogypsum, 64 parts of phosphorus high-strength gypsum, phosphorus building gypsum (CaSO 4 0.5H 2 (mass fraction greater than 85%) 16 parts, metakaolin 5 parts, carbide slag 1 part, light aggregate 1.2 parts, retarder 0.1 part, water reducing agent 0.2 part, water retaining agent 0.1 part.

[0029] The preparation method steps are as follows:

[0030] 1) Preparation of modified barium slag slurry: mix barium slag and phosphogypsum dihydrate with water at a solid-to-liquid ratio of 1:3, and stir at 45°C for 1.5 hours to obtain modified barium slag slurry;

[0031] 2) Preparation of phosphogypsum light board, adding the modified barium slag slurry obtained in step 1) and phosphorus hemihydrate gypsum, metakaolin, carbide slag, light aggregate, retarder, water reducing agent and water retaining age...

Embodiment 2

[0034] Provide a kind of phosphogypsum lightweight board prepared by barium slag, its component and weight content include:

[0035] 20 parts of barium slag, 10 parts of phosphogypsum dihydrate, 48 parts of phosphorus high-strength gypsum, 12 parts of phosphorus building gypsum, 10 parts of metakaolin, 3 parts of carbide slag, 0.5 parts of light aggregate, and 0.3 parts of water reducer.

[0036] The preparation method steps are as follows:

[0037] 1) Preparation of modified barium slag slurry: mix barium slag and phosphogypsum dihydrate with water at a solid-to-liquid ratio of 1:1.6, and stir at 55°C for 2.5 hours to obtain modified barium slag slurry;

[0038] 2) Preparation of phosphogypsum light board, adding the modified barium slag slurry obtained in step 1) and phosphorus hemihydrate gypsum, metakaolin, carbide slag, light aggregate, retarder, water reducing agent and water retaining agent into the mixer , stirred for 3 minutes, and then the stirred slurry was quickly...

Embodiment 3

[0041] Provide a kind of phosphogypsum lightweight board prepared by barium slag, its component and weight content include:

[0042] 15 parts of barium slag, 7 parts of dihydrate phosphogypsum, 60 parts of phosphorus high-strength gypsum, 15 parts of phosphorus architectural gypsum, 10 parts of metakaolin, 2 parts of carbide slag, 0.8 parts of light aggregate, 0.05 parts of retarder, 0.1 parts of water reducer part, 0.05 part of water retaining agent.

[0043] The preparation method steps are as follows:

[0044] 1) Preparation of modified barium slag slurry: mix barium slag and phosphogypsum dihydrate with water at a solid-to-liquid ratio of 1:2.3, and stir at 50°C for 2 hours to obtain modified barium slag slurry;

[0045] 2) Preparation of phosphogypsum light board, adding the modified barium slag slurry obtained in step 1) and phosphorus hemihydrate gypsum, metakaolin, carbide slag, light aggregate, retarder, water reducing agent and water retaining agent into the mixer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com