A low-noise multi-frequency sonochemical reactor and its application

A technology of chemical reactor and multi-frequency ultrasound, which is applied in the direction of chemical instruments and methods, sounding equipment, instruments, etc., can solve problems such as uneven irradiation, low yield of OH radicals, and large noise during work, and achieve system Strong oxidation ability, reduce invalid decomposition, increase the effect of cavitation bubble density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] refer to figure 1 as shown, figure 1 It is a structural schematic diagram of the multi-frequency sonochemical reactor provided in this embodiment.

[0035] In this embodiment, the multi-frequency sonochemical reactor is composed of a housing 1, a cover plate 2, a transverse ultrasonic transducer 3, a longitudinal ultrasonic transducer 4, a reaction vessel 6, an inert gas pipeline 7 and a sound-absorbing and noise-reducing layer 8 Composition, wherein: the shell 1 is a cylindrical outer shell made of stainless steel, and a cover plate 2 is installed on the top of the shell 1 to cover the shell 1.

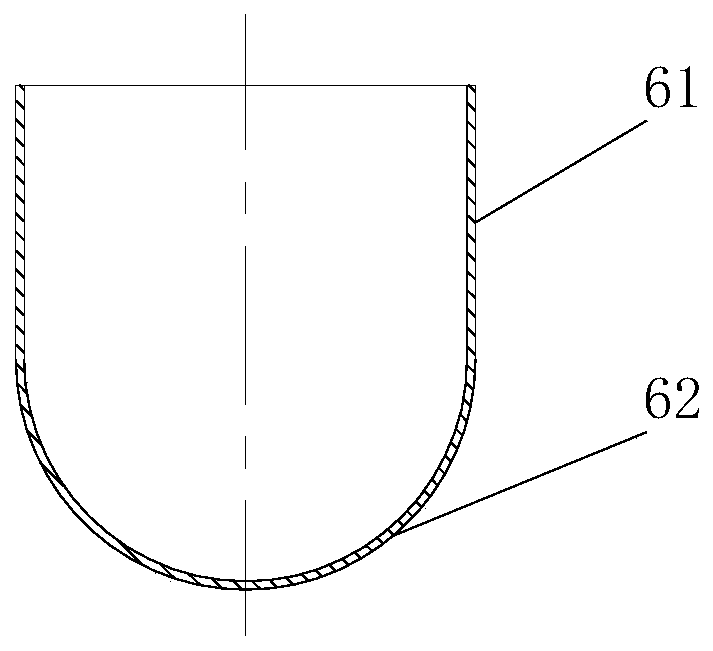

[0036] A fixed plate is arranged at the bottom of the housing 1, and the inner cavity of the housing 1 is divided into a constant temperature reaction chamber and a fixed cavity, and a reaction vessel 6 is arranged in the constant temperature reaction chamber, see figure 2, the reaction vessel 6 is made up of an arc-shaped cylinder bottom 62 and a cylinder body 61, that is,...

Embodiment 2

[0043] refer to image 3 as shown, image 3 It is a structural schematic diagram of the multi-frequency sonochemical reactor provided in this embodiment.

[0044] In this embodiment, the multi-frequency ultrasonic chemical reactor is composed of a shell 1, a cover plate 2, a transverse ultrasonic transducer 3, a longitudinal ultrasonic transducer 4, a circulating water device 5, a reaction vessel 6, an inert gas pipeline 7 and a suction The sound-reducing layer 8, the thermometer 9 and the heater 10 are composed of a cylindrical shell 1 made of heat-insulating material, and a cover plate 2 is installed on the top of the shell 1 to cover the shell 1. . A fixed plate is arranged at the bottom of the housing 1, and the inner cavity of the housing 1 is divided into a constant temperature reaction chamber and a fixed cavity. 5, that is, the circulating water device 5 that can be bathed in hot and cold water is formed between the outer wall of the reaction vessel 6 and the inner ...

Embodiment 3

[0048] In this embodiment, the reaction vessel 6 is composed of an arc-shaped cylinder bottom 62 and a cylinder body 61, that is, the cylinder body 61 and the cylinder bottom 62 are spliced to form a cylindrical structure. The cylinder bottom 62 is an arc-shaped surface, and its central angle Be 120 °, the arc radius is 8cm, and the height of cylinder body 61 is 24cm, is 3 times of cylinder bottom 62 radiuses. A transverse ultrasonic transducer group is installed on the outer wall of the junction of the cylinder bottom 62 and the cylinder body 61. The transverse ultrasonic transducer group is composed of 6 transverse ultrasonic transducers, and the 6 transverse ultrasonic transducers are 3 pairs Two opposite, the frequency of the horizontal ultrasonic transducer 3 that is arranged oppositely is the same, but the frequency of two adjacent horizontal ultrasonic transducers 3 is different, that is, the frequency of a group of horizontal ultrasonic transducers 3 that is relativel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com