High pressure resistant aluminum tank capable of achieving explosion venting and manufacturing mold and manufacturing method of high pressure resistant aluminum tank

A high-pressure resistance and explosion-venting technology, applied in the field of packaging cans, can solve the problems of low added value, poor pressure bearing capacity, corrosion of the connection port, etc., and achieve the effect of enhancing the visual stereoscopic effect, improving the product quality, and enhancing the pressure resistance capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

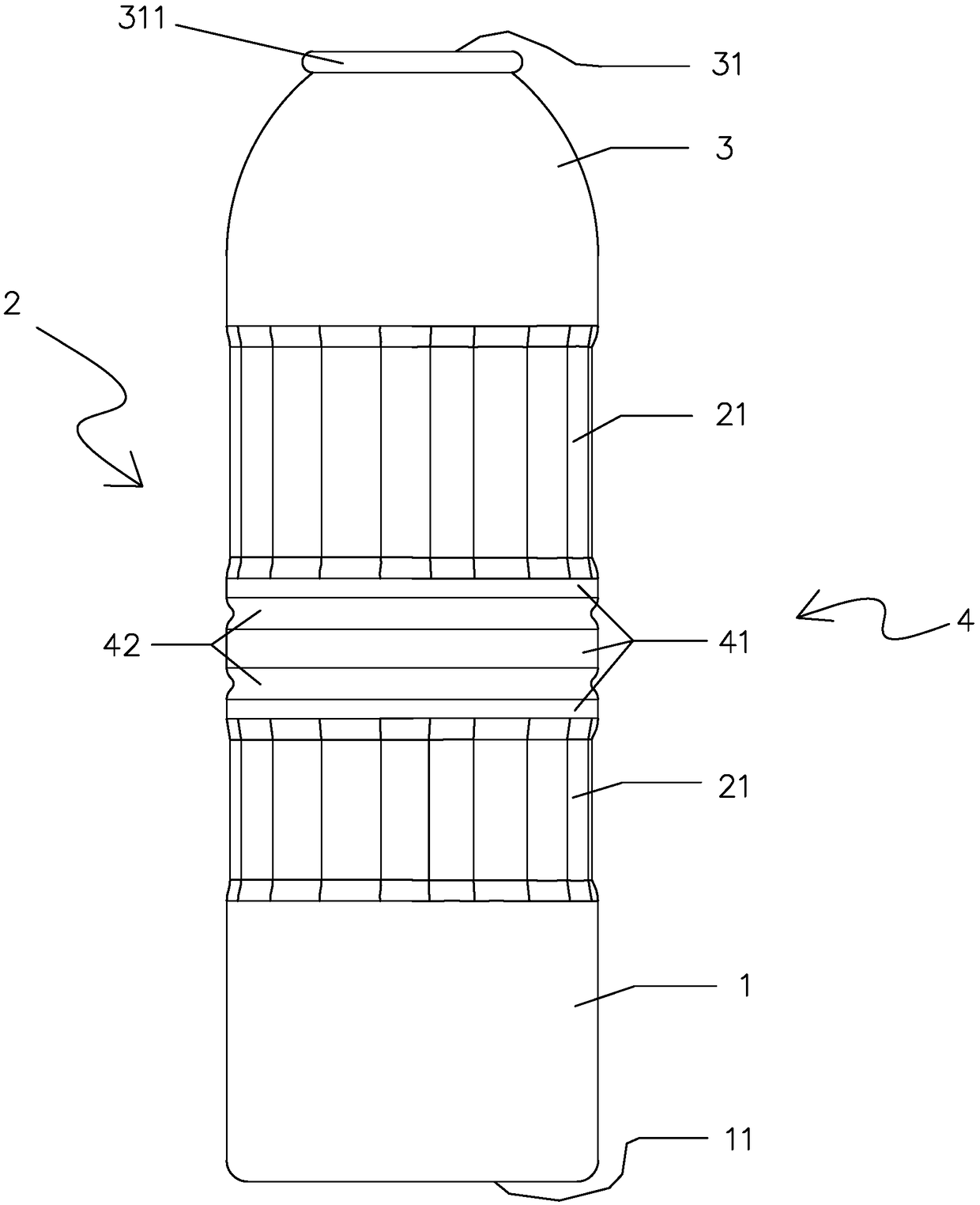

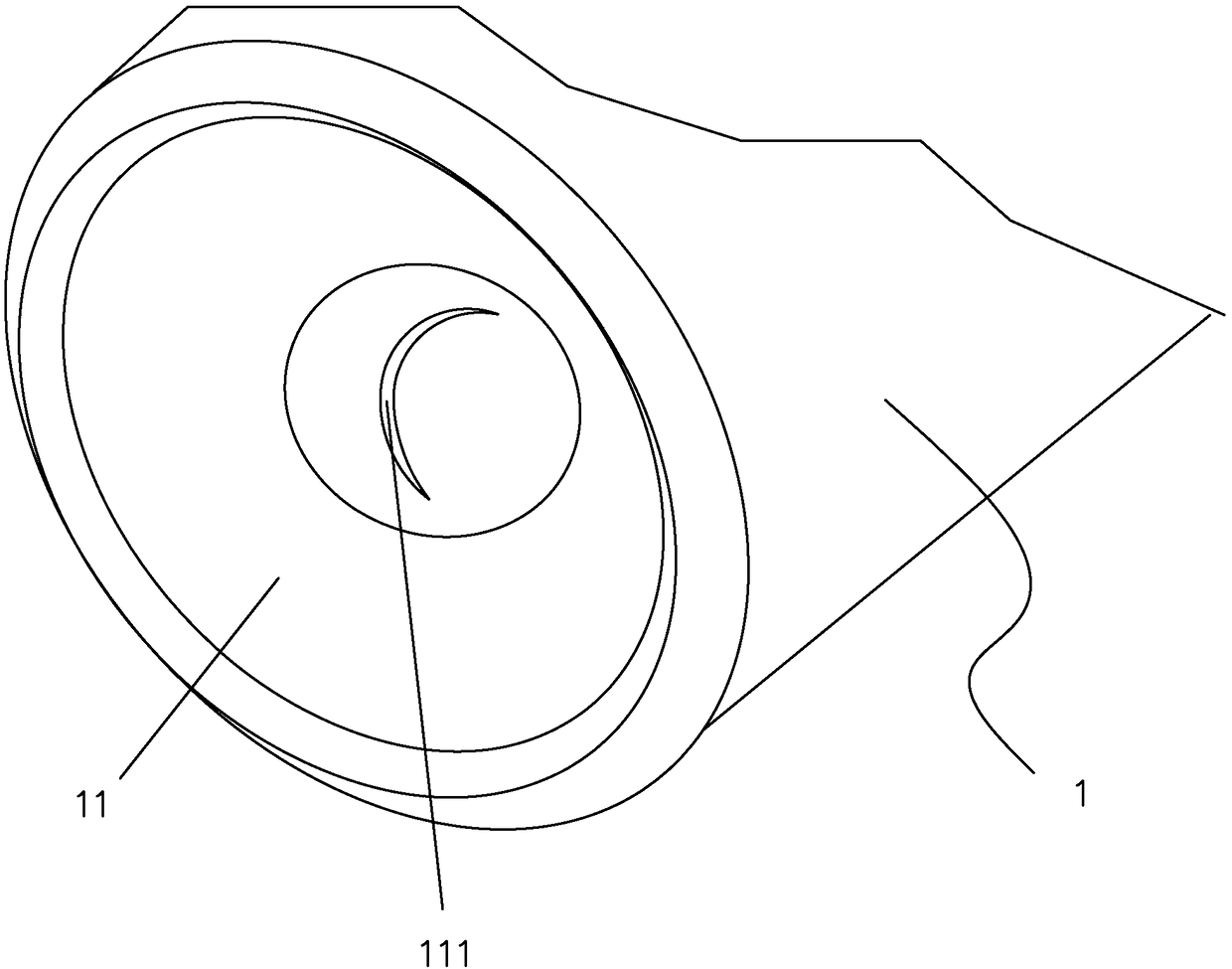

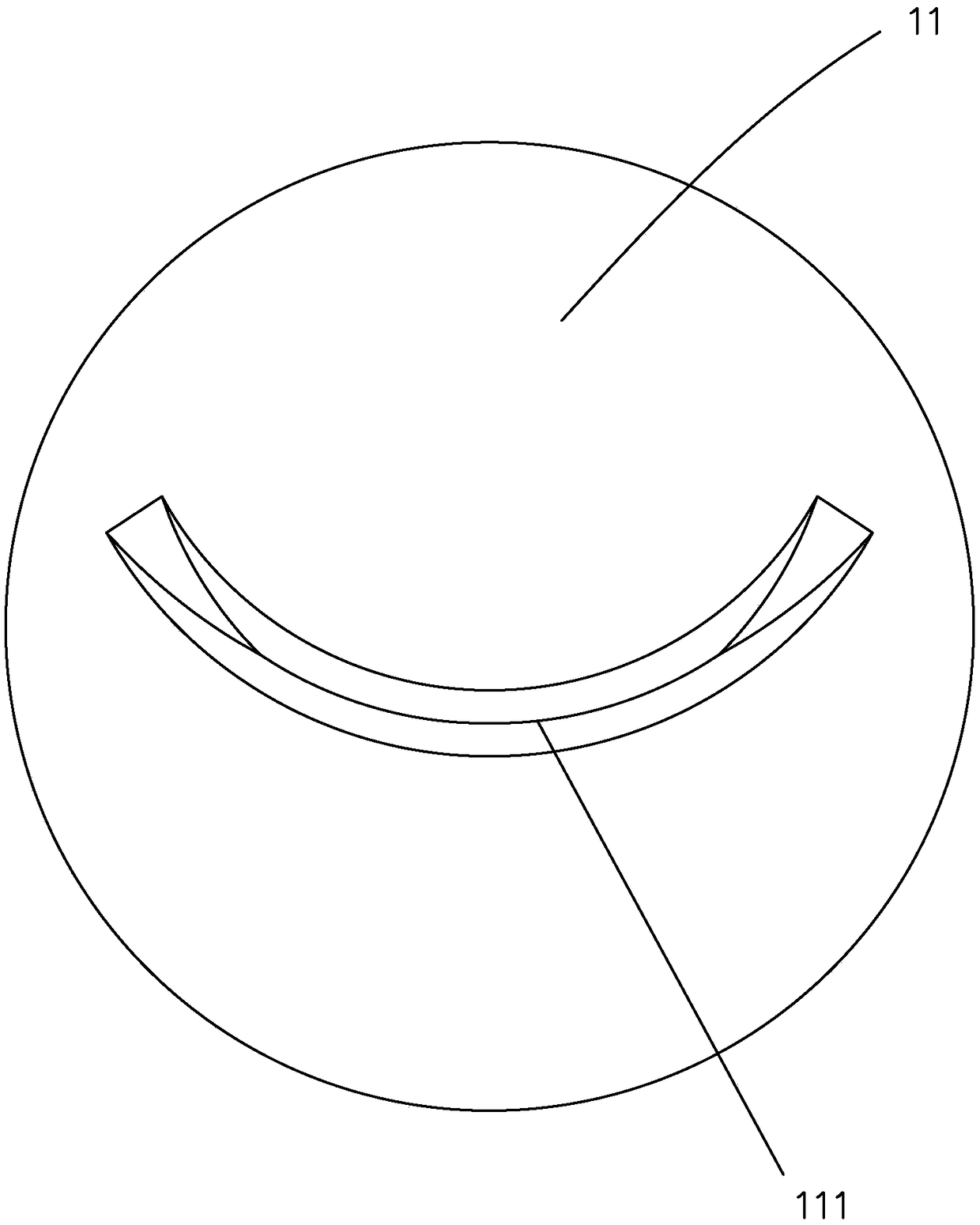

[0047] Such as figure 1 A high-pressure resistant and explosion-venting aluminum can is shown, which includes a lower section 1 of the tank, a middle section 2 of the tank body and an upper section 3 of the neck of the tank integrally formed from the bottom to the top. The lower section 1 of the can is cylindrical and has a canister Bottom 11, the top of the upper section 3 of the tank neck is provided with a tank mouth 31, the edge of the tank mouth 31 is provided with an outward flanging 311, the middle section of the tank body 2 is provided with a grasping structure 21, and the middle part of the grasping structure 21 is provided with a reinforcement structure 4 so that the grasping structure 21 is divided into two (certainly the reinforcement structure 4 can also be arranged above or below the grasping structure 21, or be located in the middle of the grasping structure 21 and divide it into three or more ), the tank bottom 11 is provided with an explosion vent thin portion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com