Battery positive electrode slurry comprising composite carbon nano-tubes

A technology of carbon nanotubes and battery positive electrodes, which is applied in battery electrodes, nanotechnology, nanotechnology, etc., and can solve the problem of no specific specification ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

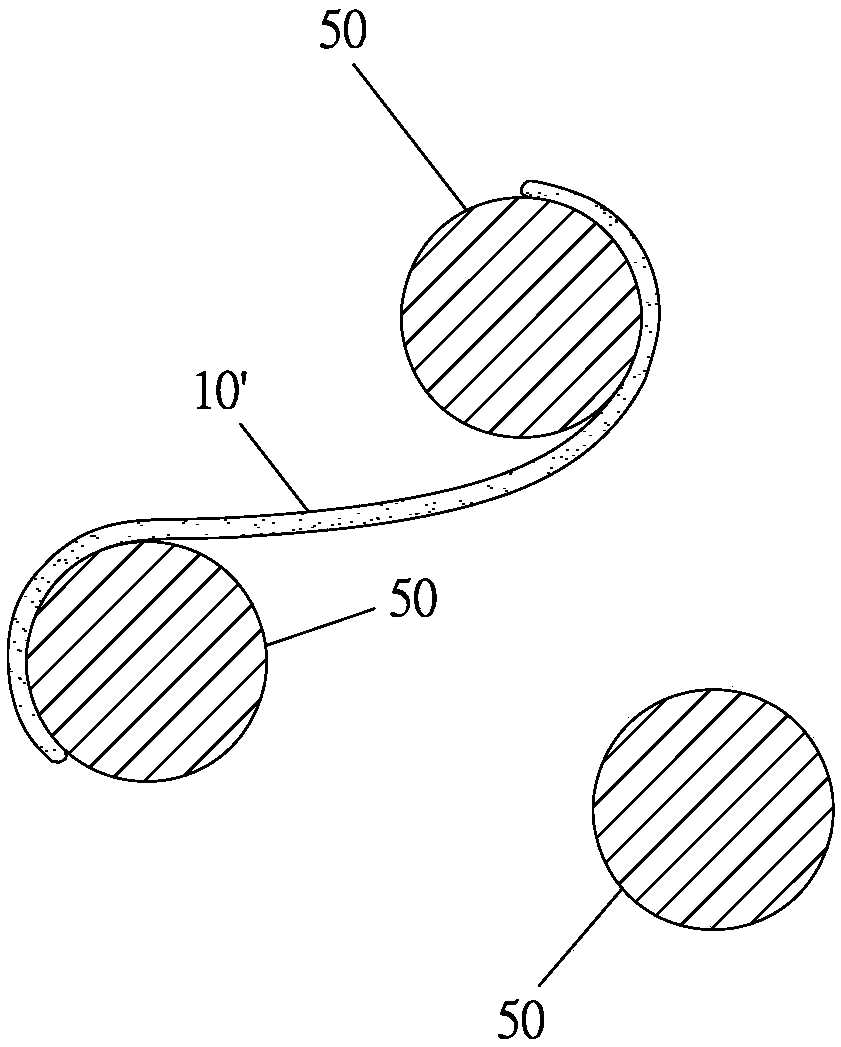

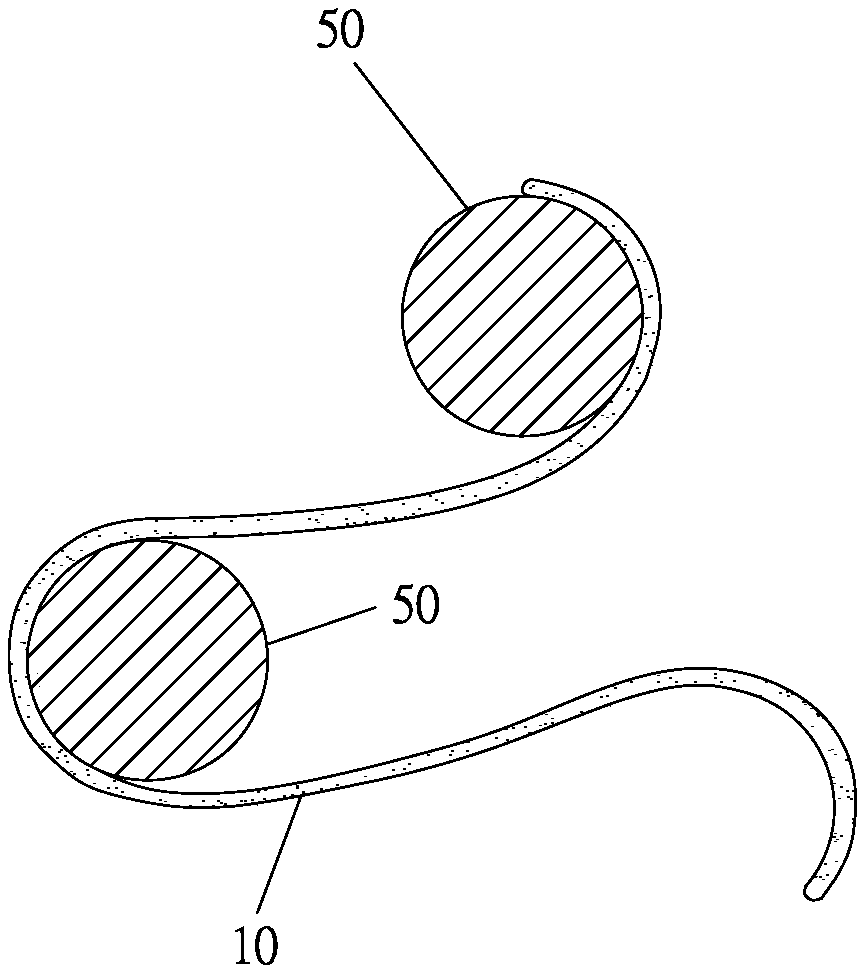

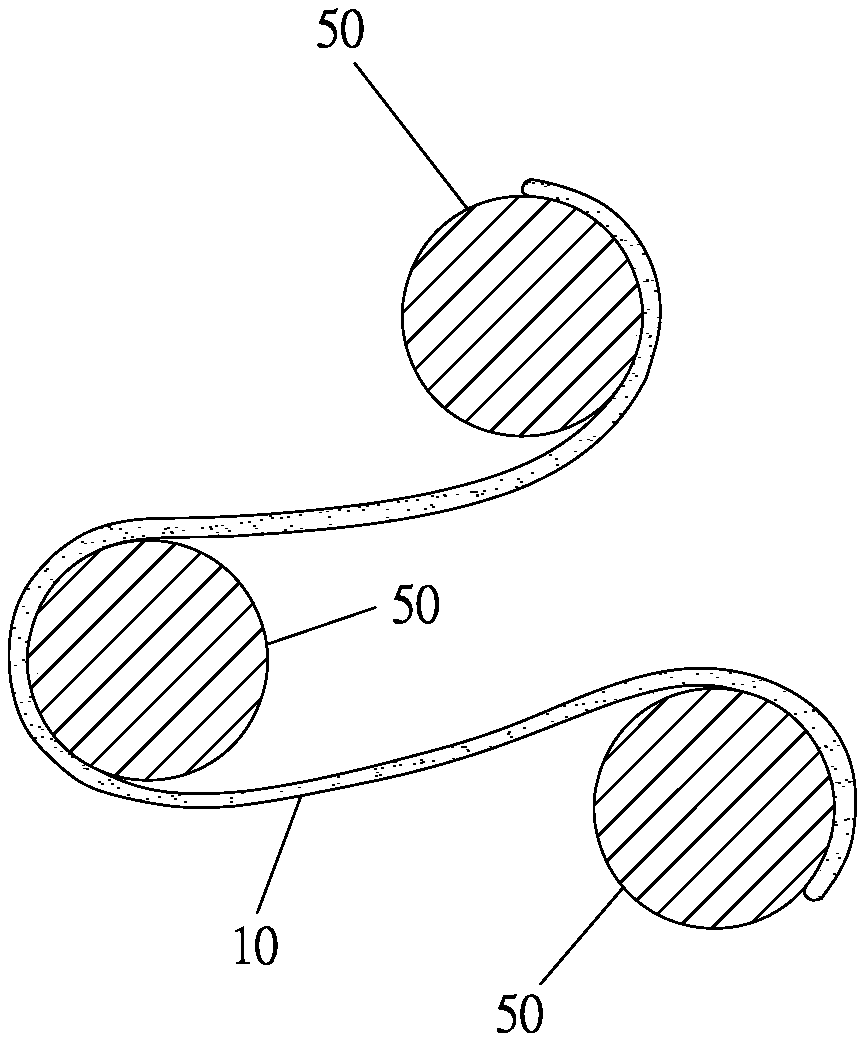

[0032] The features and advantages of the present invention can be further understood from the following description, please refer to the accompanying drawings when reading.

[0033] With regard to the structure and composition of the present invention, as well as the functions and advantages that can be produced, a preferred embodiment of the present invention will be described in detail as follows in conjunction with the accompanying drawings.

[0034] Please refer to Figure 1 to Figure 6 Shown is the positive electrode slurry for batteries comprising composite carbon nanotubes of the present invention, including the following components:

[0035] Medium-sized carbon nanotubes 11, the proportion of which accounts for the entire slurry is between 0% and 5% by weight; wherein the length of the medium-sized carbon nanotubes is between 5 μm and 15 μm, and the diameter is between 12nm and 20nm . Preferably, its purity is greater than 99%;

[0036] Long carbon nanotubes 10, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com