Light-emitting device and preparation method thereof

A light-emitting device and light-emitting layer technology, applied in the optical field, can solve problems such as cracking, peeling and falling off, increased difficulty of coating process, low porosity, etc., achieve simple and convenient processing, avoid sintering and detachment phenomenon, and facilitate coating effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

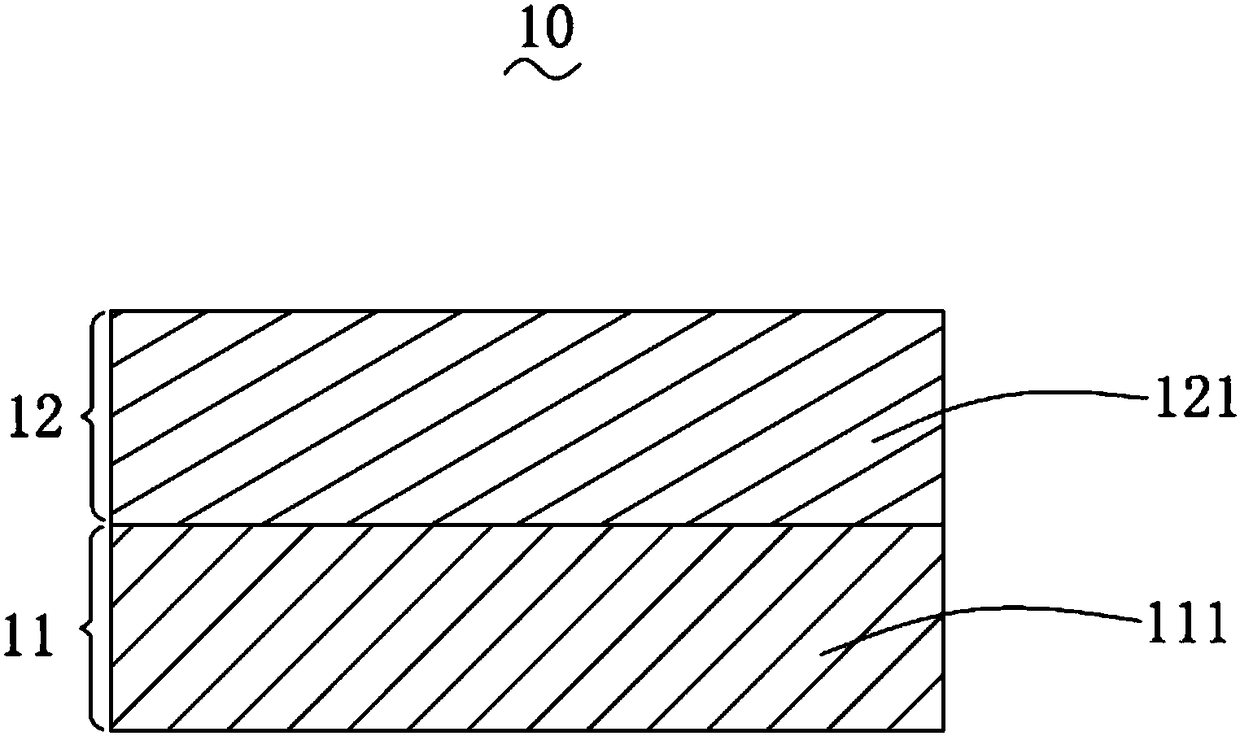

[0036] Please refer to figure 1 , the present invention provides a light-emitting device 10, the components of which include fluorescent powder and a binder for bonding.

[0037] In this embodiment, the phosphor is commercially available Y 3 Al 5 o 12 : Ce 3+ Phosphor powder; the binder is glass powder or alumina powder or Y 3 Al 5 o 12 Powder, mainly plays the role of bonding several other components. The hardness of the binder is different from that of the fluorescent powder, for example: the Mohs hardness of the glass powder is 5.5-6, the Mohs hardness of the phosphor powder is 8-8.5, and the aluminum oxide powder Mohs hardness is 9. The light-emitting device of the present invention is designed with a low-concentration layer, and the coating film can be polished on the layer. Because the hardness of the phosphor powder and the bonding medium are different, the wear state will be different when the high-concentration layer is polished, forming "relief". The low-co...

Embodiment 2

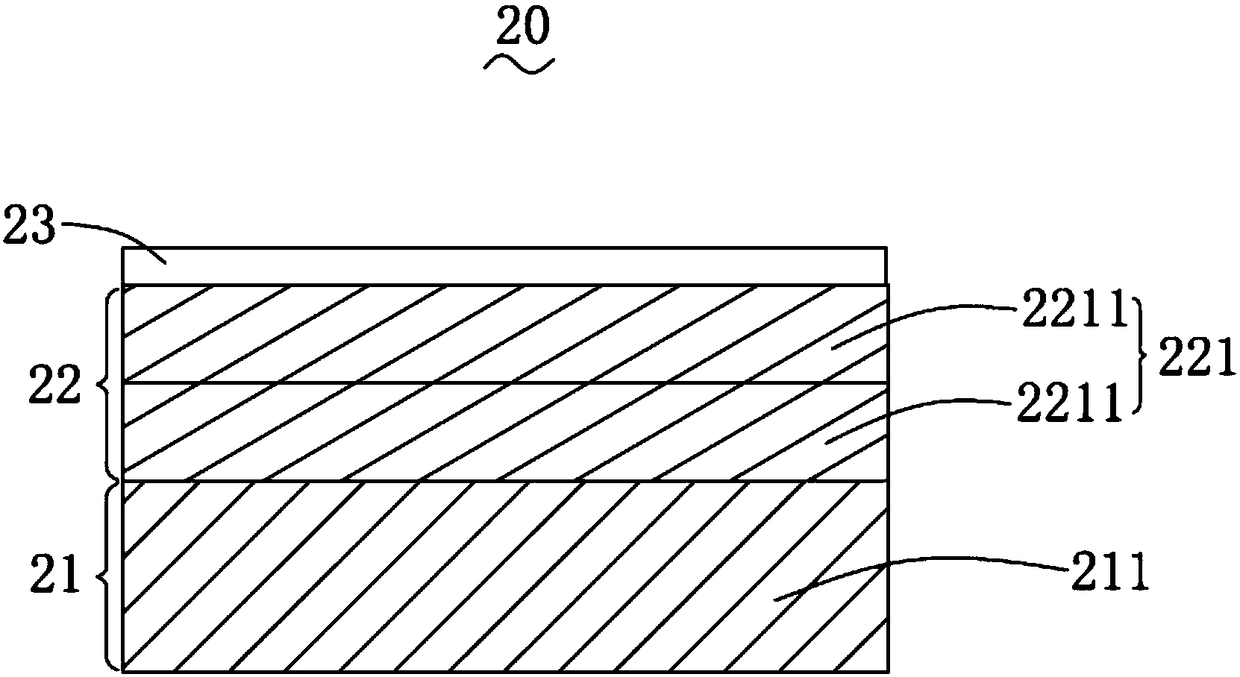

[0046] Please refer to figure 2 , the present invention provides a light-emitting device 20, the components of which include fluorescent powder and a binder for bonding.

[0047] In this embodiment, the phosphor is commercially available Y 3 Al 5 o 12 : Ce 3+ Phosphor powder; the binder is glass powder or alumina powder or Y 3 Al 5 o 12 Powder, mainly plays the role of bonding several other components. The hardness of the binder is different from that of the fluorescent powder, for example: the Mohs hardness of the glass powder is 5.5-6, the Mohs hardness of the phosphor powder is 8-8.5, and the aluminum oxide powder Mohs hardness is 9.

[0048] The light-emitting device 20 is designed to be pressed and sintered in a gradient-differentiated concentration ratio method, and includes an integrated sintered body of a light-emitting layer 21 and a functional layer 22 laminated on the light-emitting layer 21 .

[0049] The light-emitting layer 21 includes a first light-emi...

Embodiment 3

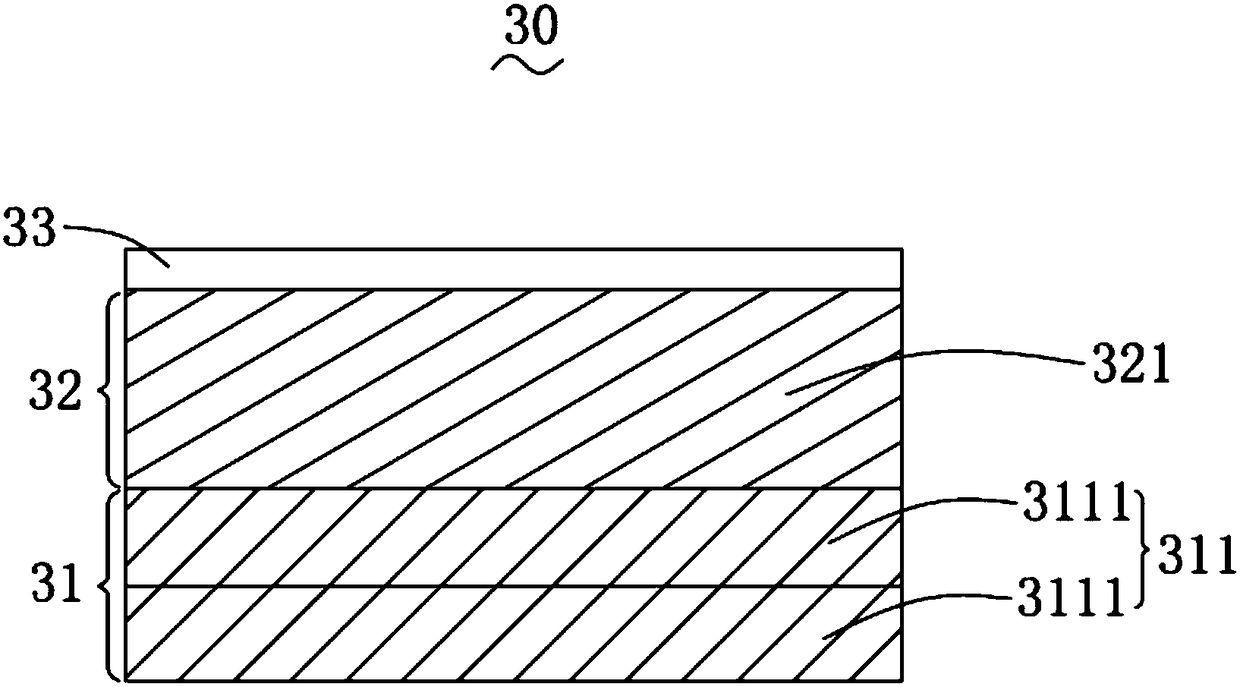

[0059] Please refer to image 3 , the present invention provides a light-emitting device 30, the components of which include fluorescent powder and a binder for bonding.

[0060] In this embodiment, the phosphor is commercially available Y 3 Al 5 o 12 : Ce 3+ Phosphor powder; the binder is glass powder or alumina powder or Y 3 Al 5 o 12 Powder, mainly plays the role of bonding several other components. The hardness of the binder is different from that of the fluorescent powder, for example: the Mohs hardness of the glass powder is 5.5-6, the Mohs hardness of the phosphor powder is 8-8.5, and the aluminum oxide powder Mohs hardness is 9. The light-emitting device of the present invention is designed with gradient concentration to form a low-concentration layer, and the coating film is polished on the layer. Because the hardness of the phosphor powder and the bonding medium are different, the wear state will be different when the high-concentration layer is polished, fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com