Variable-diameter thermoplastic optical cable protection sleeve

A technology of optical cable protection and casing, applied in the direction of optics, light guides, optical components, etc., can solve the problems of foam aging shrinkage, mud falling off, reappearance, etc., and achieve the effect of prolonging service life, not easy to aging, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

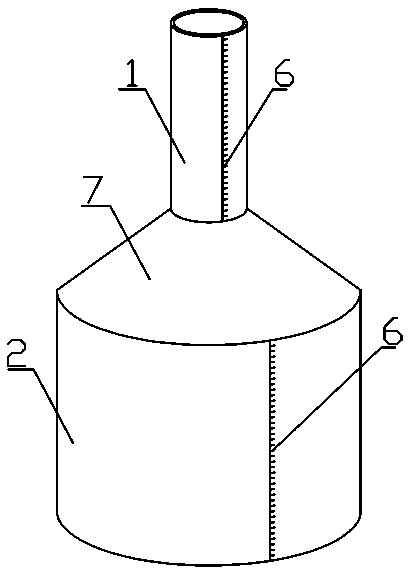

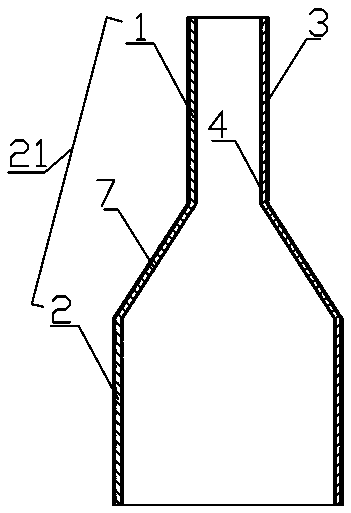

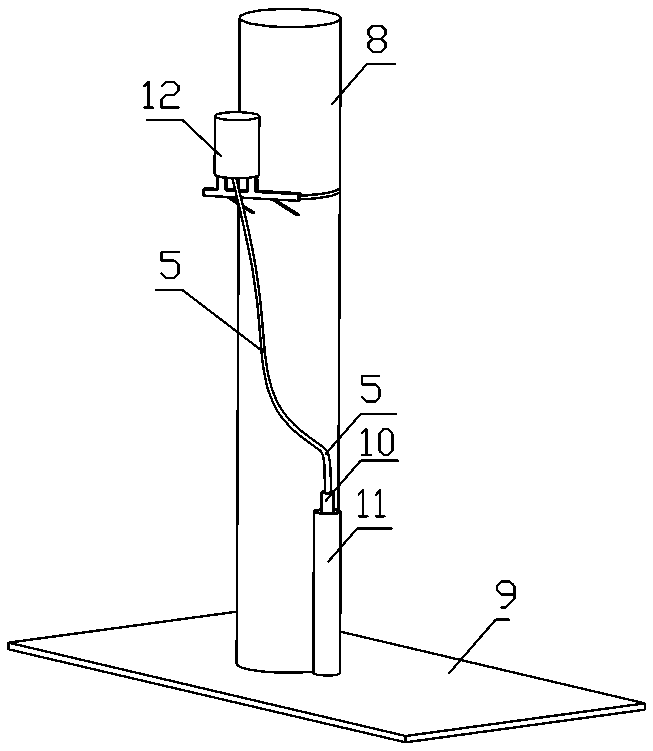

[0019] In this embodiment, a variable-diameter thermoplastic optical cable protection sleeve is a step-shaped tube body 21 composed of a sleeve A1 with a smaller diameter and a sleeve B2 with a larger diameter. In order to ensure good heat-melt performance, The pipe body is made of TPE (TPV is also applicable) thermoplastic material, and the outer and inner pipe walls of casing A1 and casing B2 are respectively coated with anti-corrosion layer 3 and waterproof layer 4 to prolong the service life of the pipe body and Protect the optical cable 5. At the same time, in order to facilitate the heat-melting convenience of the tube body, the thickness of the sleeve A1 and the sleeve B2 are both 1mm (usually 1-2mm, the thickness is too small, which is not conducive to the adhesion of the tube body, and the thickness is too large. Increase the heat fusion time and construction difficulty, but also increase the cost of materials).

[0020] In this embodiment, in order to cut the lengths...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com