High-forming nitrogen-containing austenitic stainless steel and manufacturing method thereof

A technology of austenitic stainless steel and manufacturing method, which is applied in the field of austenitic stainless steel, can solve the problems of high initial strength of materials and low formability of austenite containing nitrogen-containing nickel, so as to promote martensitic transformation and reduce material The effect of stacking fault energy

Active Publication Date: 2018-10-23

BAOSTEEL DESHENG STAINLESS STEEL

View PDF21 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The above-mentioned patented material has high C and N content, and the initial strength of the material is high; although the material is in the austenite phase at room temperature, its austenite phase is metastable, and martensitic phase transformation occurs rapidly during forming

These all lead to the formability of nitrogen-containing nickel austenite lower than that of 304

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0060] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

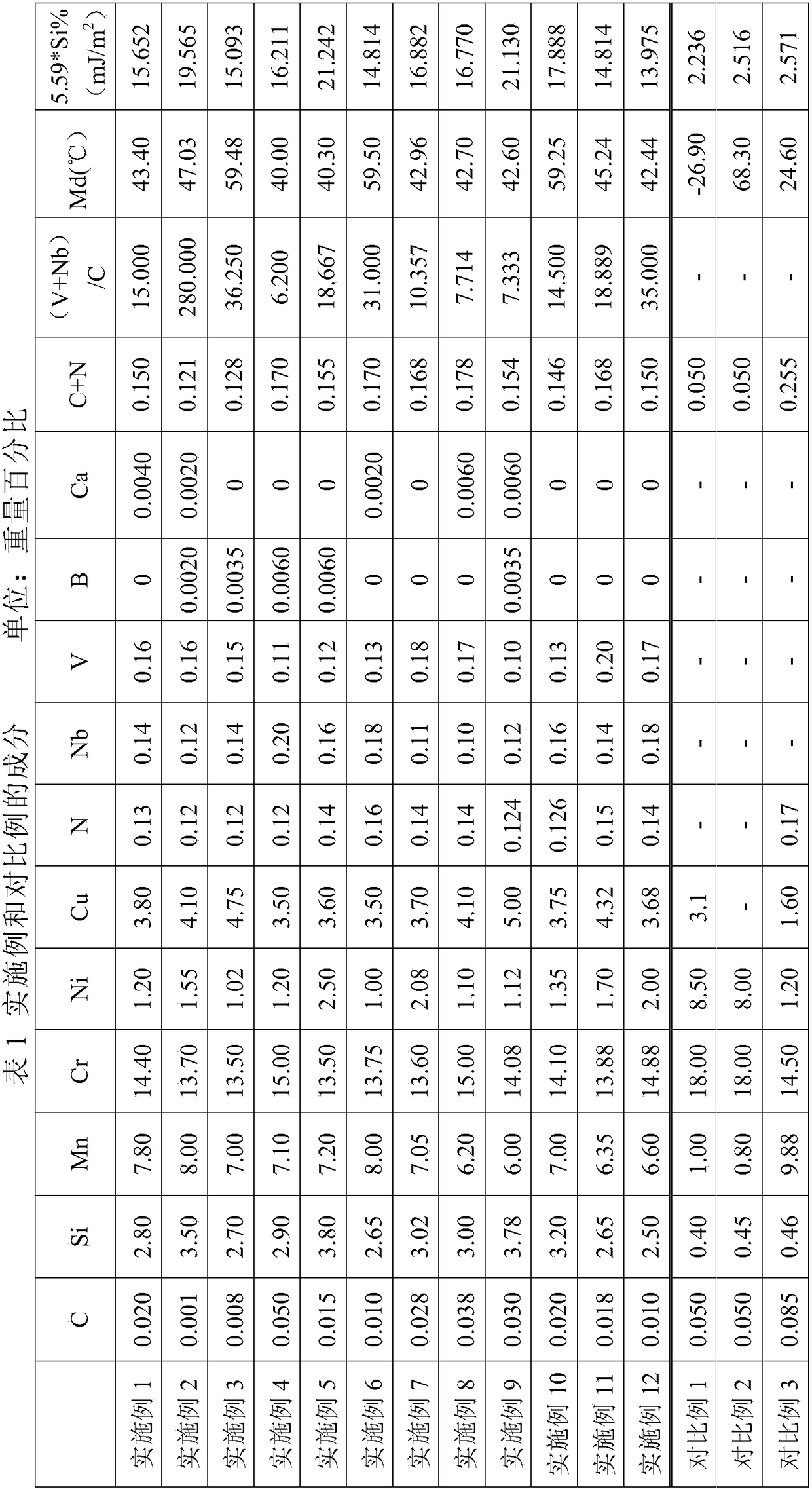

[0061] Table 1 shows the chemical composition of the steel grades of the embodiments of the present invention, and Table 1 also shows the chemical composition of the currently developed nickel-saving austenitic stainless steel and 304 austenitic stainless steel as comparative examples.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a high-forming nitrogen-containing austenitic stainless steel and a manufacturing method thereof. The composition of the steel comprises the following components of, by weight,0.001-0.05% of C, 2.50-3.80% of Si, 6.0-8.0% of Mn, 13.5-15.0% of Cr, 1.0-2.5% of Ni, 0.12-0.15% of N, 3.5-5.0% of Cu, less than or equal to 0.004% of S, 0.1-0.2% of V, 0.1-0.2% of Nb, and the balance Fe and inevitable impurities, wherein C+N is less than or equal to 0.18% , (V + Nb) / C is larger than or equal to 5, the content of Si multiplied by 5.59 mJ / m<2> is greater than or equal to 14 mJ / m<2>, Md30 / 50 is 40-70 DEG C, the average grain size is larger than or equal to 90 microns, and the hardness is less than or equal to HV180. According to the preparation method disclosed by the invention, the Ni is replaced with nitrogen alloying, and the Mn, the Cu and the like which obtain austenite structures are added; the Si and the like are added, so that lower stacking fault energy is remarkably reduced; the initial hardness of a material is reduced, and the temperature of the MD30 / 50 is controlled, so that the martensite phase changes slowly in the strain process; the erishen value is larger than or equal to 14.5, LDR is larger than or equal to 2.4, the requirements of complex forming is met, and the performance is close to 304 DDQ with high forming and high cost, so that the steel can be widely applied to industries such as electronics, instruments and apparatus, products and the like.

Description

technical field [0001] The invention relates to austenitic stainless steel, in particular to a highly formed nitrogen-containing austenitic stainless steel and a manufacturing method thereof. Background technique [0002] Austenitic stainless steel 304 has good formability and is often used in deep drawing fields, such as stainless steel water cups and thermos bottles. In the field of deep drawing with particularly high requirements, such as water cups or sinks formed at one time, conventional 304 cannot meet the requirements when processing deep-drawn products, and cracks and pull-through phenomena are prone to occur, which affects the qualified rate of finished products. [0003] For this reason, a special deep-drawing material 304DDQ has been developed. Compared with ordinary 304, the nickel content of 304DDQ is increased from 8.0% to 8.5%, and about 3.5% of Cu is added. The austenite of the material has a more matching stability and the extension of the material The rat...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22C38/34C22C38/58C22C38/42C22C38/46C22C38/48C21D8/02C21D1/26

CPCC21D1/26C21D8/0226C21D8/0236C21D8/0273C21D2211/001C21D2211/008C22C38/001C22C38/004C22C38/34C22C38/42C22C38/46C22C38/48C22C38/58

Inventor 张伟陈孟许海刚虞广群陈旭杜伟吴狄峰强少明

Owner BAOSTEEL DESHENG STAINLESS STEEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com