Egg-laying hen feed capable of improving egg productivity

A technology for laying hen feed and egg-laying performance, applied in the field of laying hen feed, can solve the problems of no commercial value, broken egg shell, increased cost, etc., and achieve the effects of reducing the egg breaking rate, reducing the pH value, and promoting utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

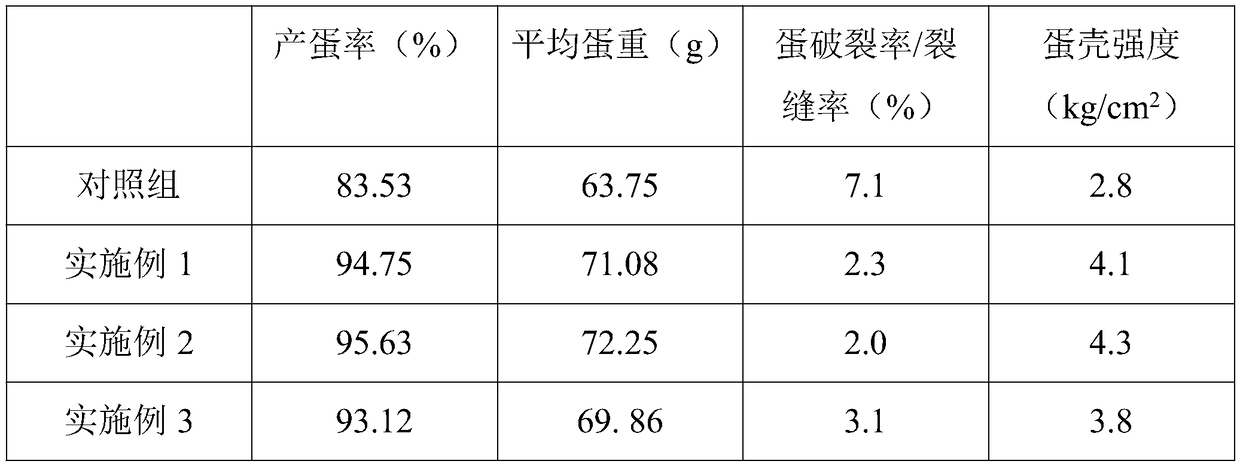

Examples

Embodiment 1

[0024] A feed for laying hens that improves egg production performance is calculated by weight percentage and is made of the following raw materials:

[0025] Corn 55%, soybean meal 16%, rice bran meal 8%, corn gluten meal 2%, fish scale enzymatic hydrolysis extract 0.4%, Bacillus subtilis 0.03%, cotton meal 7.96%, peanut meal 10%, compound amino acid 0.2%, compound enzyme 0.25%, trace elements 0.1% and traditional Chinese medicine additives 0.06%.

[0026] The preparation method of fish scale enzymolysis extract comprises the following steps:

[0027] 1) Weigh fish scales and crush them to obtain fish scale powder, then soak them in an acid solution for 2.5 hours, and use an ultrasonic instrument to perform ultrasonic vibration treatment during the soaking; the acid solution consists of: 10g / L of H 3 BO 3 , 16g / L lactic acid, the balance is deionized water.

[0028] 2) Centrifuge the acid solution in step 1) to obtain acid-treated fish scale powder, then clean it with wate...

Embodiment 2

[0034] A feed for laying hens that improves egg production performance is calculated by weight percentage and is made of the following raw materials:

[0035] Corn 60%, soybean meal 10%, rice bran meal 11%, corn gluten meal 2%, fish scale enzymatic hydrolysis extract 0.1%, Bacillus subtilis 0.02%, cotton meal 10%, peanut meal 6.49%, compound amino acid 0.1%, compound enzyme 0.15%, trace elements 0.1% and traditional Chinese medicine additives 0.04%.

[0036] The preparation method of fish scale enzymolysis extract comprises the following steps:

[0037] 1) Weigh fish scales and crush them to obtain fish scale powder, then soak them in an acid solution for 2 hours, and use an ultrasonic instrument to perform ultrasonic vibration treatment during the soaking; the acid solution consists of: 8g / L H 3 BO 3 , 20g / L lactic acid, and the balance is deionized water.

[0038] 2) Centrifuge the acid solution in step 1) to obtain acid-treated fish scale powder, then clean it with water...

Embodiment 3

[0044] A feed for laying hens that improves egg production performance is calculated by weight percentage and is made of the following raw materials:

[0045] Corn 50%, soybean meal 15%, rice bran meal 12%, corn gluten powder 1.38%, fish scale enzymatic hydrolysis extract 0.6%, Bacillus subtilis 0.04%, cotton meal 10%, peanut meal 10%, compound amino acid 0.3%, compound enzyme 0.45%, trace elements 0.15% and traditional Chinese medicine additives 0.08%.

[0046] The preparation method of fish scale enzymolysis extract comprises the following steps:

[0047]1) Weigh fish scales and crush them to obtain fish scale powder, then soak them in an acid solution for 3 hours, and use an ultrasonic instrument to perform ultrasonic vibration treatment during the soaking; the acid solution consists of: 12g / L of H 3 BO 3 , 12g / L lactic acid, the balance is deionized water.

[0048] 2) Centrifuge the acid solution in step 1) to obtain acid-treated fish scale powder, then clean it with cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com