Method and equipment for controlling top coal cavability with pulse hydraulic fracturing

A technology of hydraulic fracturing and cavitation, which is applied in the field of pulse hydraulic fracturing to control cavitation and cavitation of top coal. The coal effect is not obvious and other problems, to achieve the effect of wide practicability, convenient construction, simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

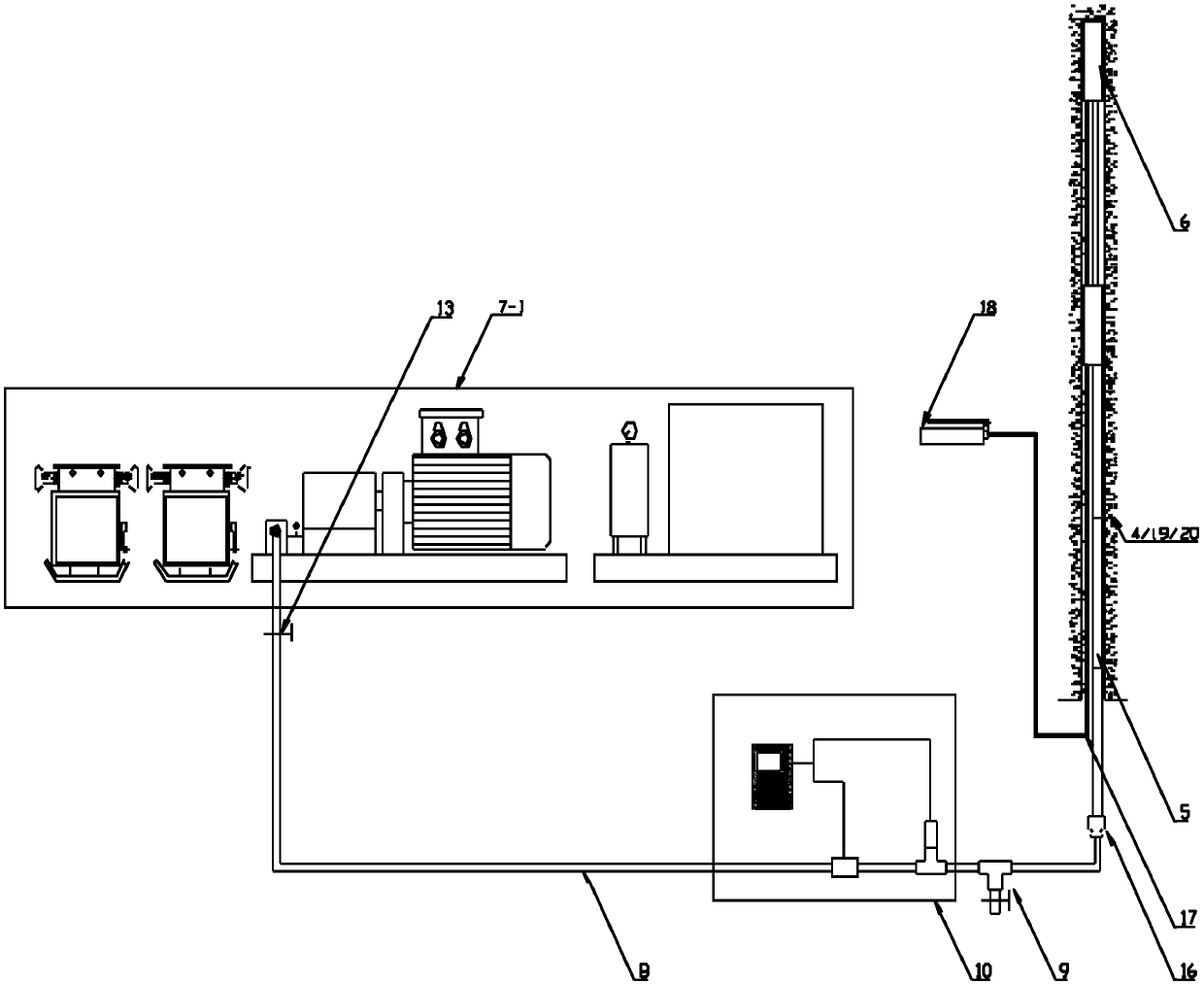

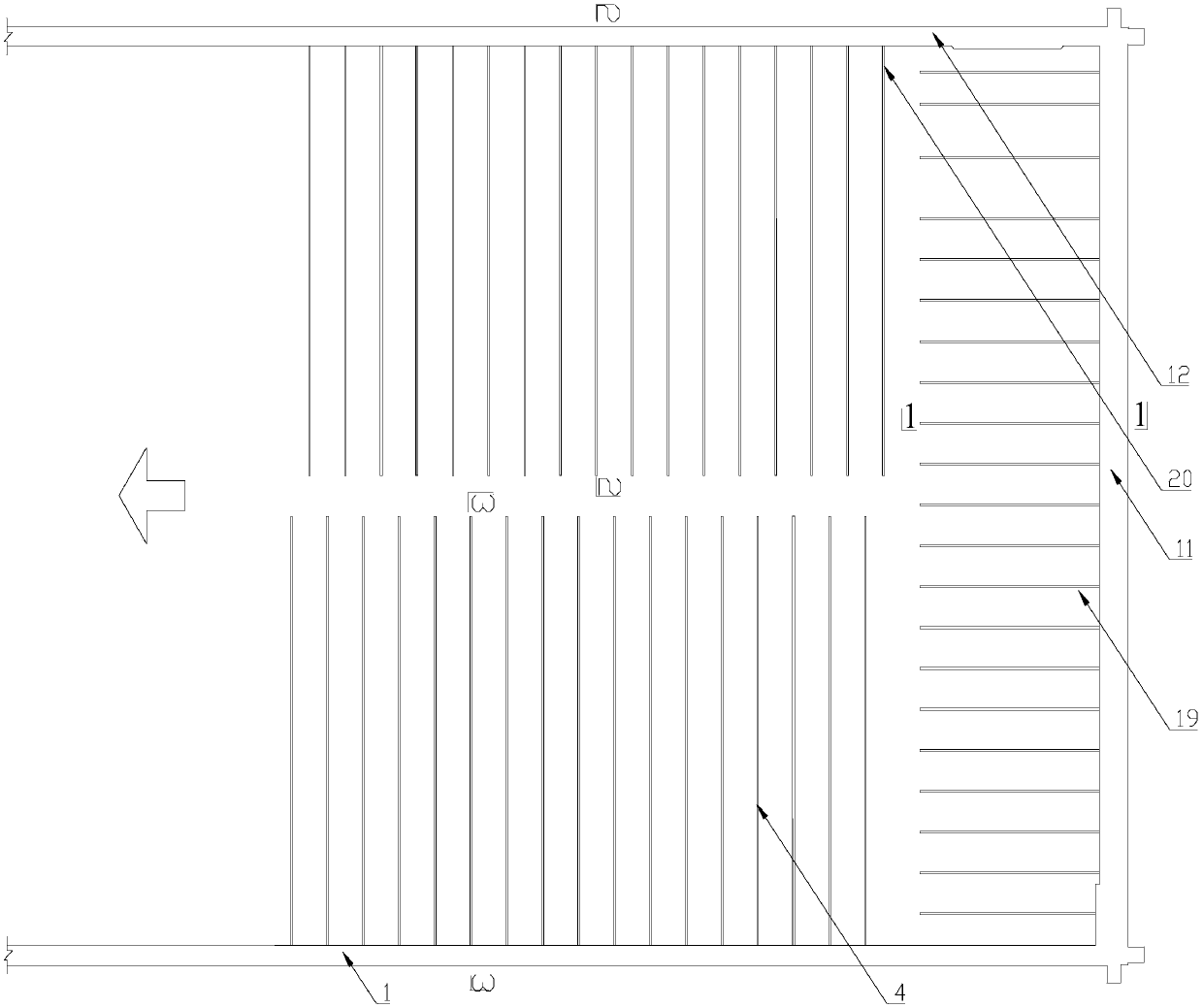

[0055] Such as figure 1 , Figure 3 to Figure 6 As shown, the average thickness of the coal seam of a certain mine is 7.5m, the direct roof is gravelly coarse sandstone, sometimes mudstone, sandy mudstone, with an average thickness of 6.32m; the old roof is coarse sandstone with an average thickness of 4.06m, and the direct bottom is siltstone, with an average The thickness is 2.10m. Open cut in working face: the rectangular roadway is supported by bolts, nets and cables, with a net width of 8.5m, a net height of 3.2m, and a net section area of 27.2m 2 . Transportation along the working face: The rectangular roadway is supported by the combination of anchors, nets and cables, with a net width of 4.6m, a net height of 3.2m, and a net section area of 14.72m 2 . Working face return wind tunnel: The support method is the same as the transportation tunnel, rectangular roadway, clear width 4.6m, clear height 3.2m, net section area 14.72m 2 .

[0056] Such as image 3 with Figure...

Embodiment 2

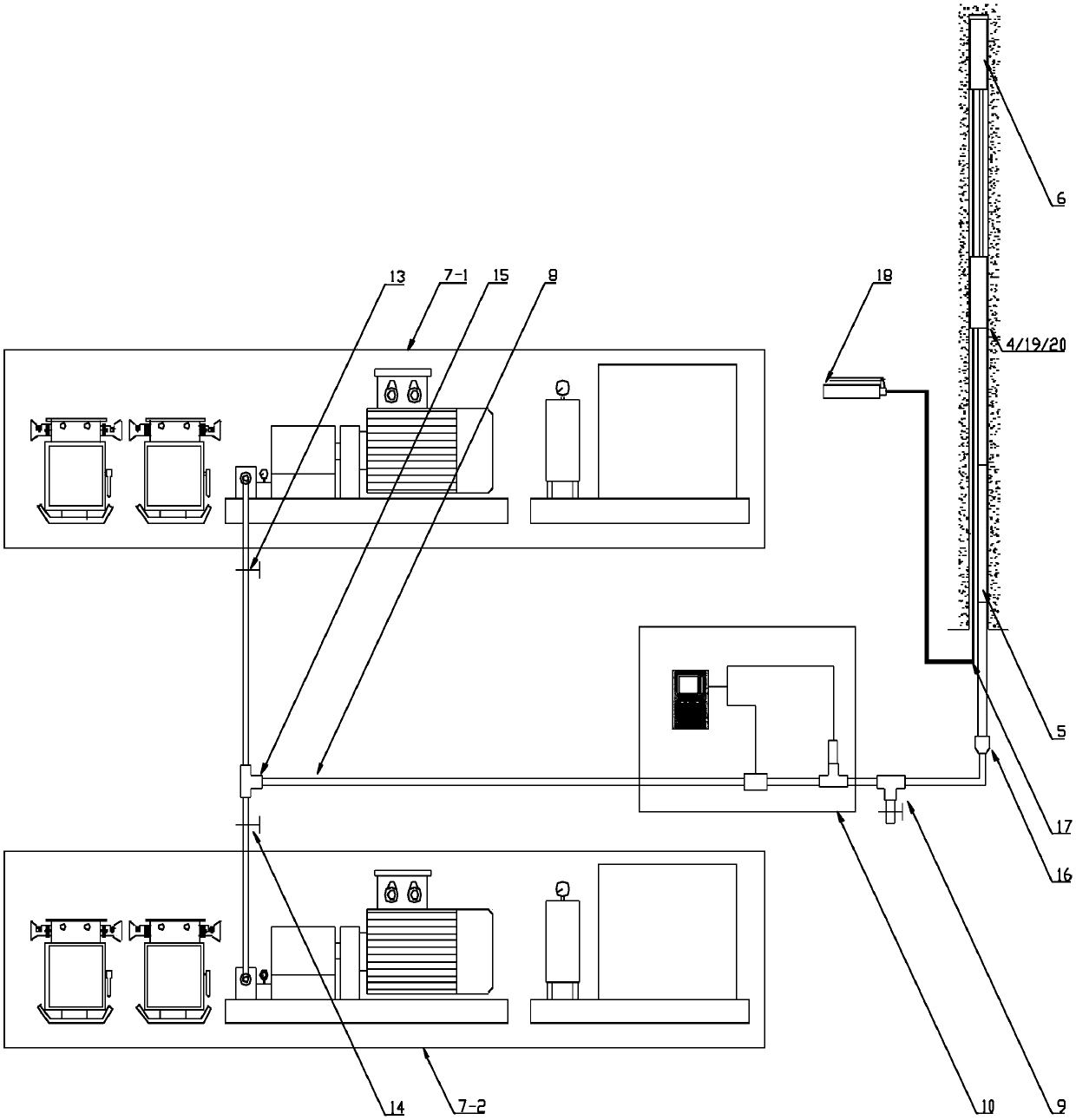

[0077] Such as figure 2 , Figure 3 to Figure 6 As shown, the average thickness of a coal seam in a certain mine is 9m. The direct roof is gravelly coarse sandstone, sometimes mudstone or sandy mudstone, with an average thickness of 7m; the old roof is coarse sandstone with an average thickness of 4m, and the direct bottom is siltstone with an average thickness of 2m. Open cut in working face: the rectangular roadway is supported by bolts, nets and cables, with a net width of 9m, a net height of 3m, and a net section area of 27m 2 . Transportation along the working face: The rectangular roadway is supported by the combination of anchors, nets and cables, with a net width of 4.6m, a net height of 3.2m, and a net section area of 14.72m 2 . Working face return wind tunnel: The support method is the same as the transportation tunnel, rectangular roadway, clear width 4.6m, clear height 3.2m, net section area 14.72m 2 .

[0078] Such as image 3 with Figure 4 As shown, a long b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com