A method and equipment for controlling the cavitation of top coal by pulse hydraulic fracturing

A technology of hydraulic fracturing and cavitation, which is applied in the field of controlling top-coal cavitation and pulse hydraulic fracturing to control cavitation of top-coal. The coal effect is not obvious and other problems, to achieve the effect of wide practicability, convenient construction, simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

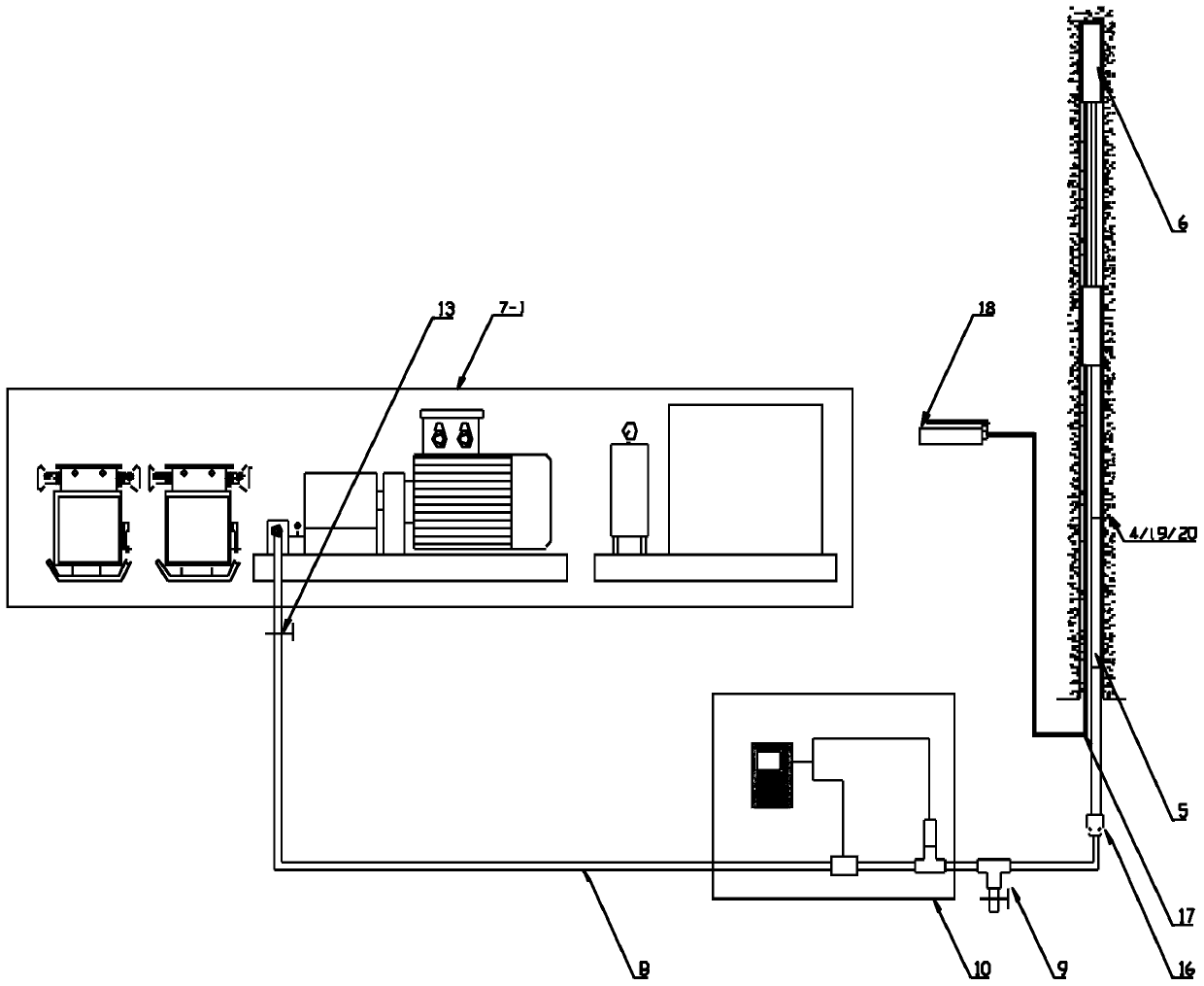

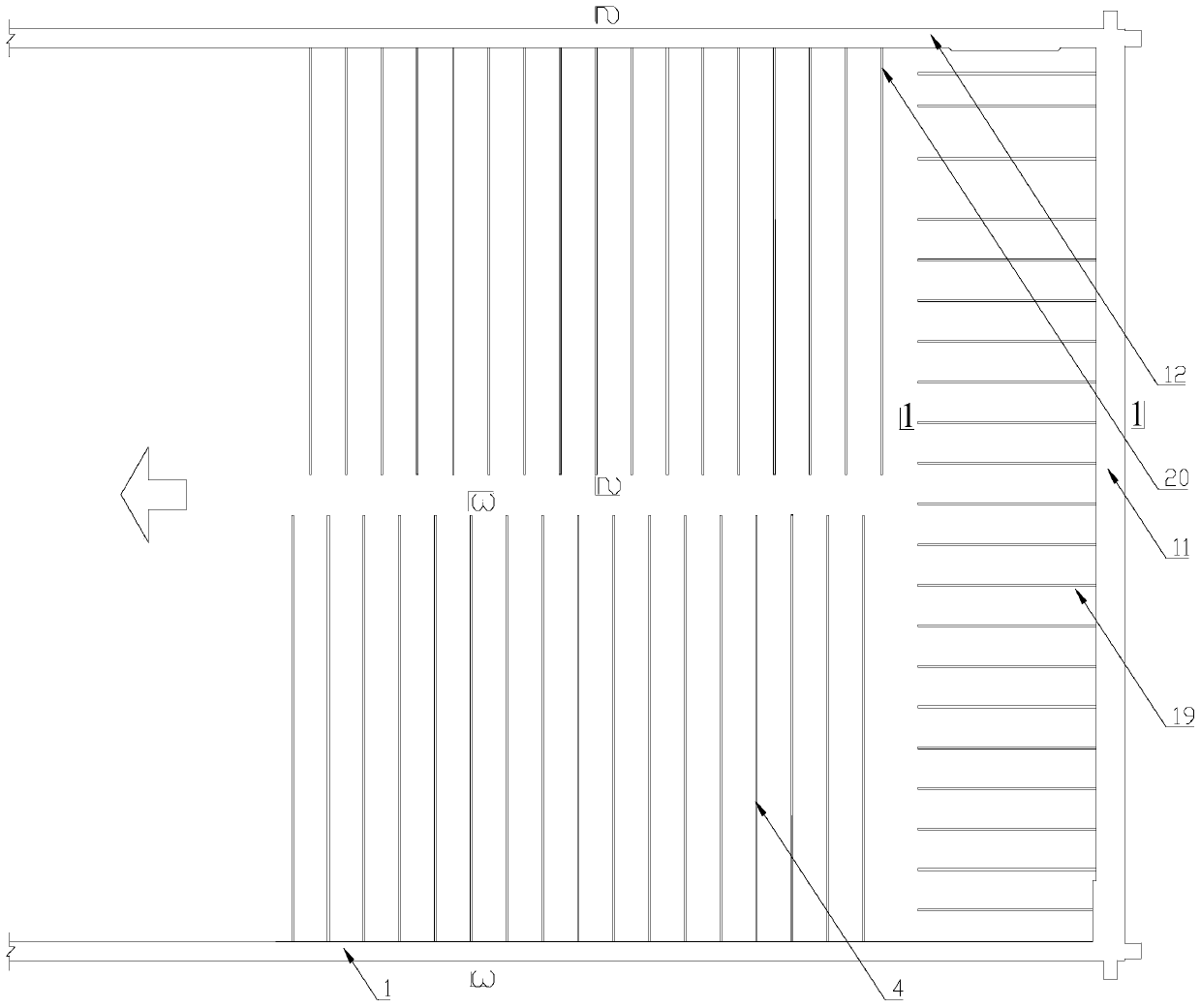

[0055] Such as figure 1 , Figure 3 to Figure 6 As shown, the average thickness of a coal seam in a certain mine is 7.5m, and the immediate roof is pebble-bearing coarse sandstone, sometimes mudstone and sandy mudstone, with an average thickness of 6.32m; the old roof is coarse sandstone, with an average thickness of 4.06m, and the immediate bottom is siltstone, with an average thickness of Thickness 2.10m. Cutting face at working face: Rectangular roadway supported by anchors, nets and cables, net width 8.5m, net height 3.2m, net sectional area 27.2m 2 . Transport trough on the working face: use anchors, nets and cables to jointly support the rectangular roadway, with a net width of 4.6m, a net height of 3.2m, and a net cross-sectional area of 14.72m 2 . Return air trough on the working face: the support method is the same as that of the transport trough, rectangular roadway with a net width of 4.6m, a net height of 3.2m, and a net cross-sectional area of 14.72m 2 . ...

Embodiment 2

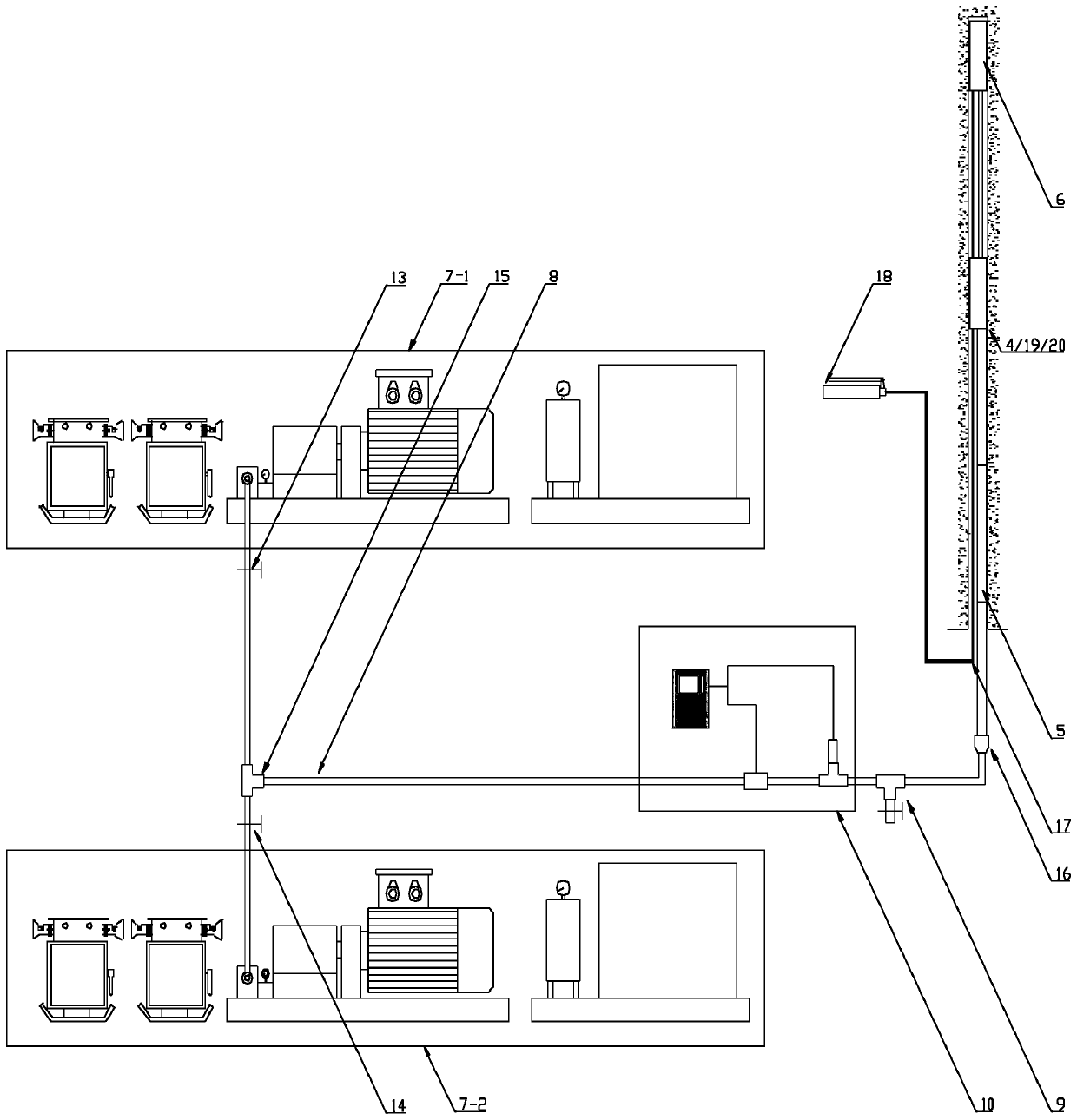

[0077] Such as figure 2 , Figure 3 to Figure 6 As shown, the average thickness of a coal seam in a certain mine is 9m. The immediate top is pebble-bearing coarse sandstone, sometimes mudstone and sandy mudstone, with an average thickness of 7m; the old top is coarse sandstone, with an average thickness of 4m, and the immediate bottom is siltstone, with an average thickness of 2m. Working face cut-out: use anchors, nets and cables to jointly support the rectangular roadway, with a net width of 9m, a net height of 3m, and a net sectional area of 27m 2 . Transport trough on the working face: use anchors, nets and cables to jointly support the rectangular roadway, with a net width of 4.6m, a net height of 3.2m, and a net cross-sectional area of 14.72m 2 . Return air trough on the working face: the support method is the same as that of the transport trough, rectangular roadway with a net width of 4.6m, a net height of 3.2m, and a net cross-sectional area of 14.72m 2 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com