Preparation method of low-haze polyvinyl butyral membrane

A technology of polyvinyl butyral film and polyvinyl butyral resin, which is applied in the field of preparation of low-haze polyvinyl butyral film, can solve the problem that haze quality is difficult to improve and haze remains and other issues, to achieve the effect of improving transparency and perception, and improving security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] Partially acetalized polyvinyl butyral resin and plasticizer are mixed, extruded and cast into PVB film, and the specific steps are as follows:

[0027] Put PVB resin powder, mixed plasticizer, and additives into the twin-screw extruder in a metered manner. The length-to-diameter ratio is 36:1. Melting and plasticizing under certain conditions, through a T-shaped mold with an opening of 0.5mm-0.8mm, a PVB film with a thickness of 0.76mm is formed, cooled and shaped, and coiled into a finished product.

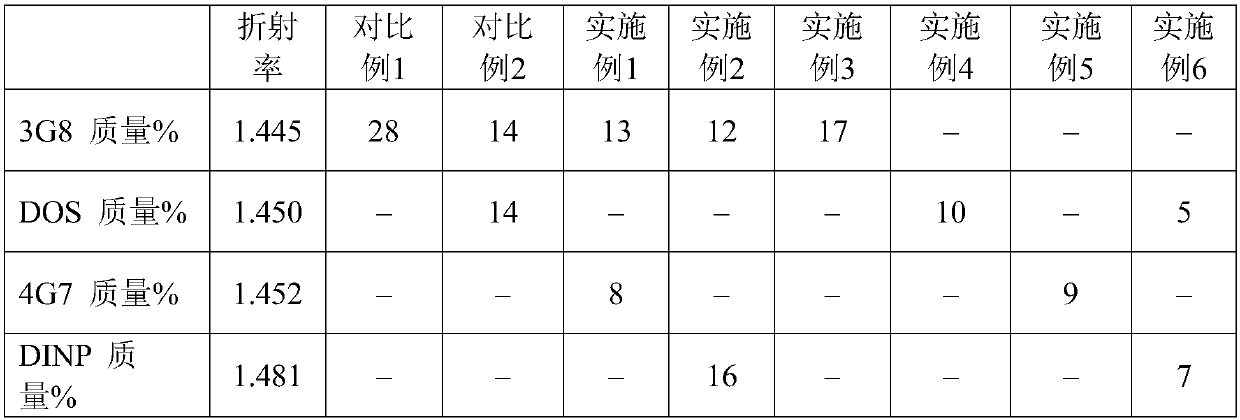

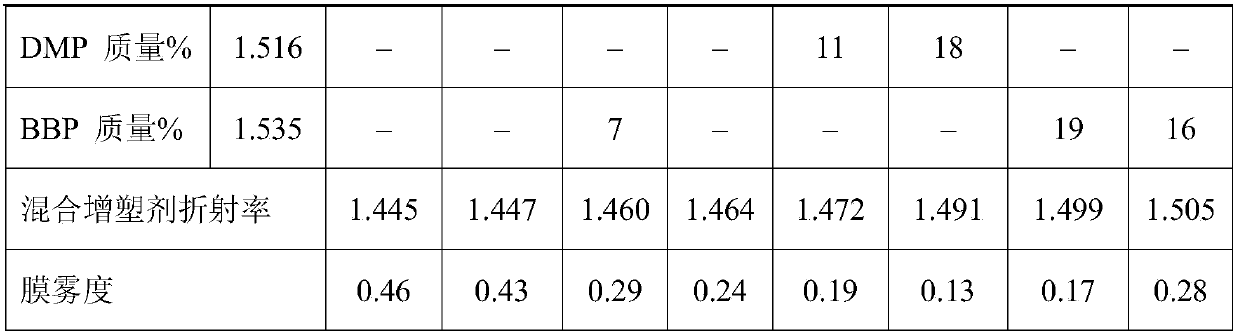

[0028] On the basis of selecting 28%, which is representative in the industry, as the mass % of the mixed plasticizer in the film, according to the composition of the mixture given in the table below, the film was extruded by the above method, and the haze of the film was tested.

[0029]

[0030]

[0031] Wherein: mass % represents the mass percentage of the plasticizer in the total material composition of the film.

[0032] 3G8 represents triethylene glycol diis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com