Aluminium oxide settlement tank full-direction scab cleaning device and application method thereof

A technology for cleaning devices and settling tanks, applied in the direction of liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as high labor intensity, environmental pollution, and affecting the use efficiency of settling tanks, and achieve cleaning short cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

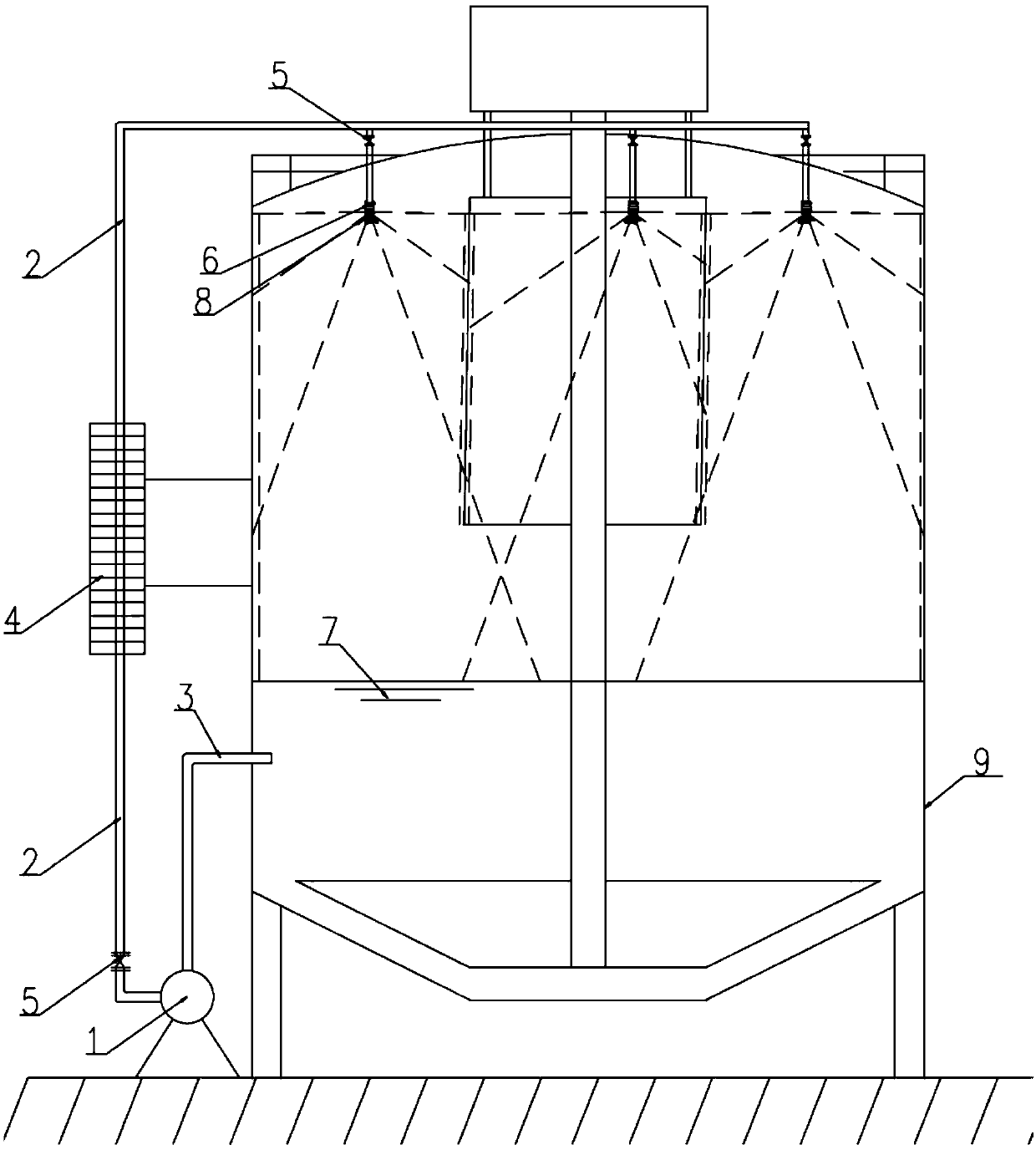

Method used

Image

Examples

Embodiment 1

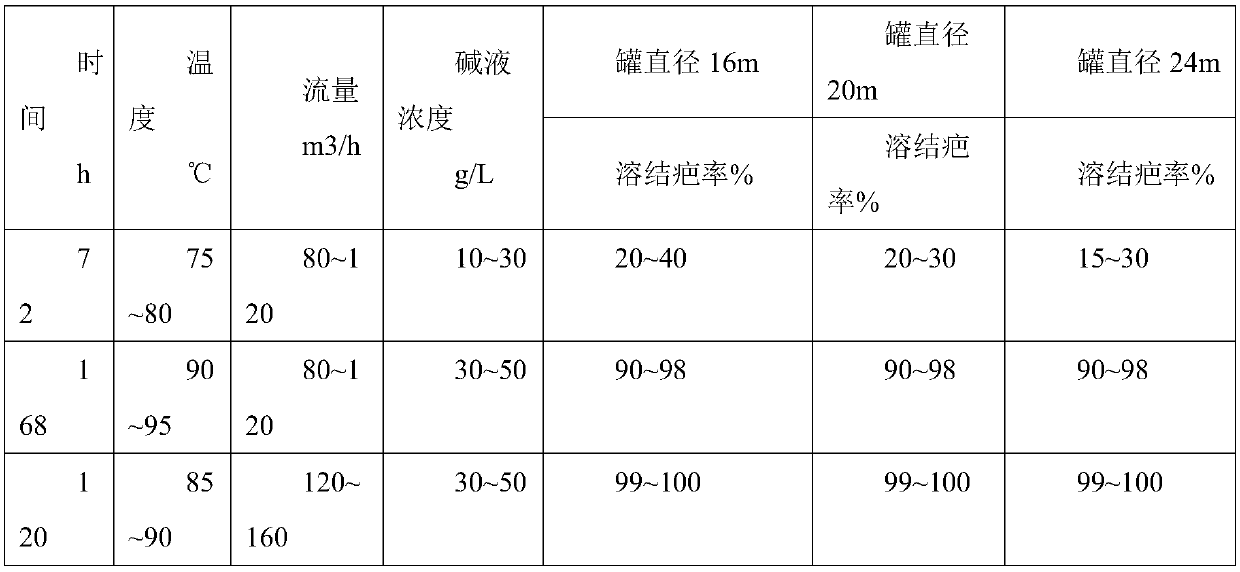

[0031] Said control valve 5 sets the flow rate of lye 7 to 80m3 / h.

[0032] The method for using the all-round scab cleaning device for the alumina settling tank specifically includes the following steps:

[0033] Step 1, the lye 7 with a concentration of 10g / L is produced by proportioning the thickness of the scab;

[0034] Step 2, open the circulating pump 1 and the control valve 5, so that the lye 7 can circulate in the circulating header 2;

[0035] Step 3: When the temperature of the lye 7 is heated to 75°C by the heating device 4, open the control valve 5 arranged above the scab cleaner 6, so that the heated lye 7 is sprayed from the scab cleaner 6, and And the lower cleaning settling tank 9, the cleaning time is 72h;

[0036] Step 4. Then, when the temperature of the lye 7 is heated to 90° C., the cleaning time is 168 hours;

[0037] Step 5. Finally, when the temperature of the lye 7 is heated to 85° C., the cleaning time is 120 hours, so that the settling tank 9 is ...

Embodiment 2

[0039] Said control valve 5 sets the flow rate of lye 7 to 120m3 / h.

[0040] The method for using the all-round scab cleaning device for the alumina settling tank specifically includes the following steps:

[0041] Step 1, the lye 7 with a concentration of 30g / L is produced by proportioning the thickness of the scab;

[0042] Step 2, open the circulating pump 1 and the control valve 5, so that the lye 7 can circulate in the circulating header 2;

[0043] Step 3: When the temperature of the lye 7 is heated to 78°C by the heating device 4, open the control valve 5 arranged above the scab cleaner 6, so that the heated lye 7 is sprayed from the scab cleaner 6, and And the lower cleaning settling tank 9, the cleaning time is 72h;

[0044] Step 4. Then, when the temperature of the lye 7 is heated to 93° C., the cleaning time is 168 hours;

[0045] Step 5. Finally, when the temperature of the lye 7 is heated to 87° C., the cleaning time is 120 hours, so that the settling tank 9 is...

Embodiment 3

[0047] The flow rate of lye 7 is set to 160m3 / h by the control valve.

[0048] The method for using the all-round scab cleaning device for the alumina settling tank specifically includes the following steps:

[0049] Step 1, the lye 7 with a concentration of 50g / L is produced by proportioning the thickness of the scab;

[0050] Step 2, open the circulating pump 1 and the control valve 5, so that the lye 7 can circulate in the circulating header 2;

[0051] Step 3, when the temperature of the lye 7 is heated to 80°C by the heating device 4, the control valve 5 arranged above the scab cleaner 6 is opened, so that the heated lye 7 is ejected from the scab cleaner 6, and the And the lower cleaning settling tank 9, the cleaning time is 72h;

[0052] Step 4. Then, when the temperature of the lye 7 is heated to 95° C., the cleaning time is 168 hours;

[0053] Step 5. Finally, when the temperature of the lye 7 is heated to 90° C., the cleaning time is 120 hours, so that the settlin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com