Oil and water separator

An oil-water separator and oil scraping tank technology, which is applied in liquid separation, separation method, immiscible liquid separation, etc., can solve the problems of low degree of automation control, poor oil scraping effect, inconvenient discharge of sundries, etc., to achieve automation The effect of high degree of control and convenient recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

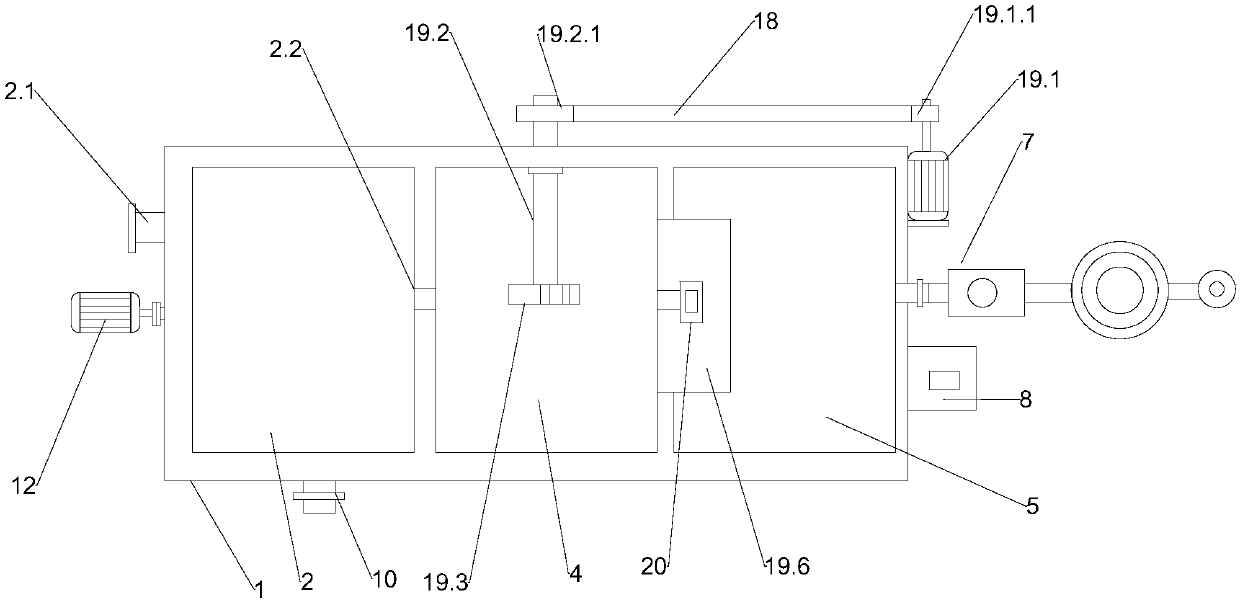

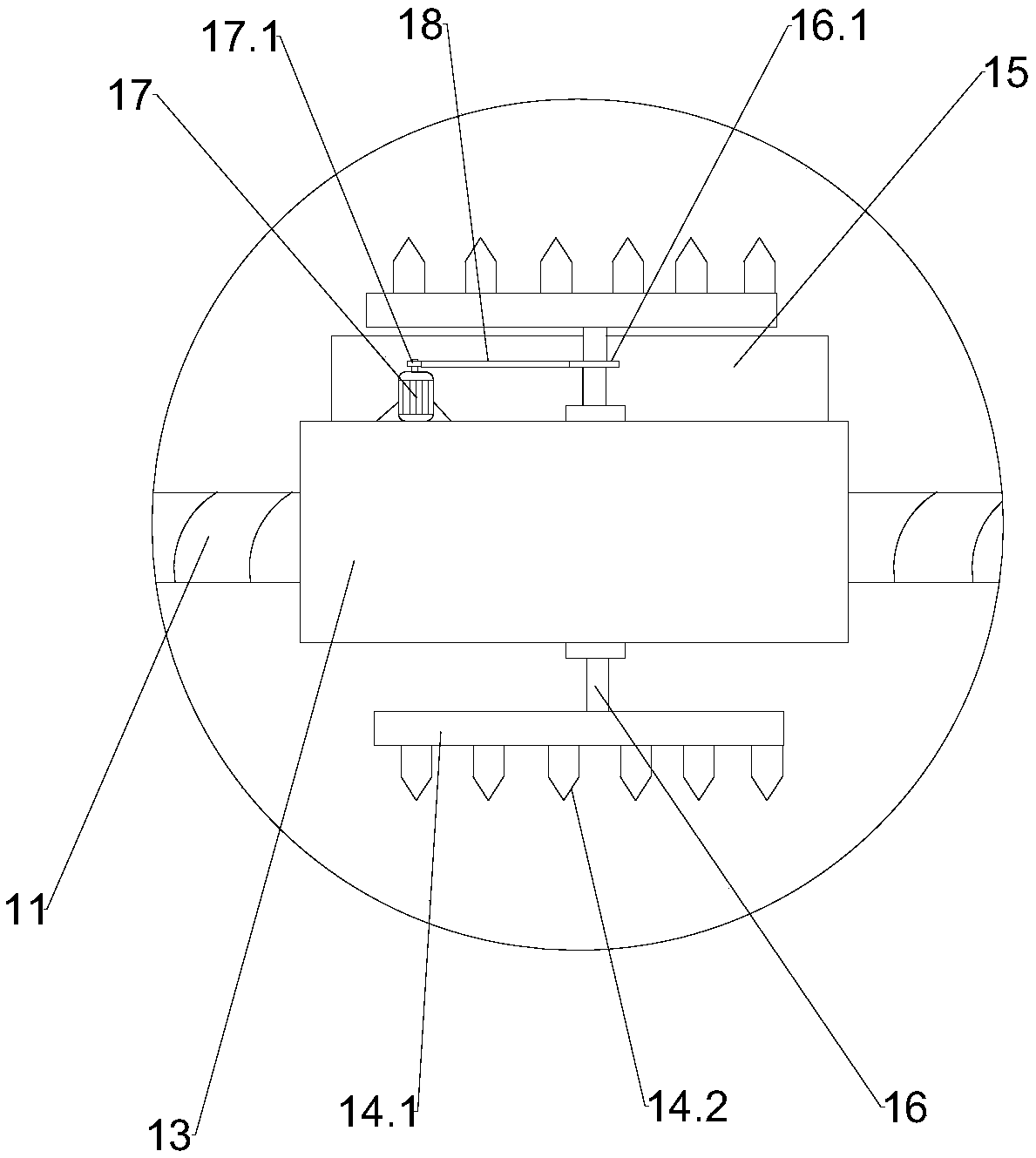

[0028] An oil-water separator, such as Figure 1~2 As shown, it includes a box body 1, a settling tank 2 arranged inside the box body, a sundry disposal tank 3, an oil scraping tank 4, an oil collection tank 5, a water collection tank 6, and a drainage pump group 7 and a control box arranged outside the box body 8. Wherein, the settling tank 2 is a conical tank, the upper side of the settling tank 2 is provided with a feed port 2.1, and the other side is provided with an oil-water overflow port 2.2, and the position of the oil-water overflow port is lower than that of the feed port. A miscellaneous flow port 2.3 is provided below the settling tank 2, and a miscellaneous flow opening valve 9 is arranged on the settling tank at the miscellaneous flow port 2.3. The sundries treatment tank 3 is arranged below the settling tank 2 to receive the sundries from the settling tank 2 . The top of the debris treatment tank 3 is open, and the bottom is provided with a debris discharge po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com