Combined tubular high-pressure seepage leaching test device

A test device and high-pressure technology, which is applied in soil material testing, material inspection products, etc., can solve the problems of low precision of leaching tests, and achieve the effects of automatic control and monitoring, good use prospects, and strong corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

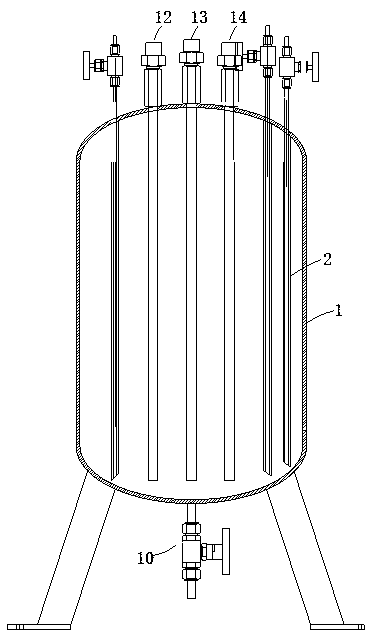

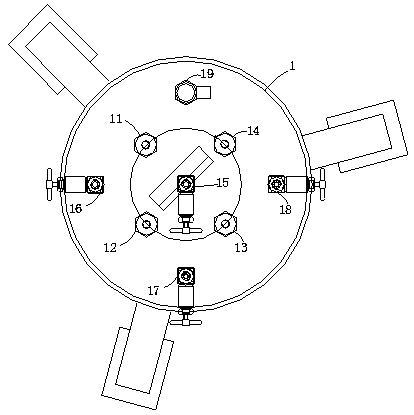

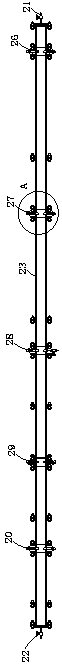

[0026] Such as Figure 1 to Figure 4 As shown, a combined tubular high-pressure seepage leaching test device includes a high-pressure storage tank 1, and more than one combined tubular reactor 2 is arranged in the high-pressure storage tank 1, and the end of the combined tubular reactor 2 is separated from the high-pressure storage tank. The top of 1 passes through, the top of the combined tubular reactor 2 is connected to the liquid inlet valve 21, the bottom of the combined tubular reactor 2 is connected to the liquid outlet valve 22, and the liquid outlet valve 22 is located in the high pressure storage tank 1, the combined tubular reactor 2. The interior is filled with leached ore. The combined tubular reactor 2 is assembled by splicing and assembling multi-section tubular units 23. The joints of the tubular units 23 form monitoring sections, and the number of monitoring sections is multiple;

[0027] The monitoring section includes a pH monitoring section, an OPR monitori...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com