An online moisture detection device and method for a bulk material

A detection device and detection method technology, applied to measuring devices, weighing by removing certain components, weighing materials, etc., can solve problems such as inability to meet online rapid detection, low accuracy, and high labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0102] According to the second embodiment of the present invention, there is provided an online moisture detection method for bulk materials or an online moisture detection method for bulk materials using the above-mentioned moisture online detection device for bulk materials, the method comprising the following steps:

[0103] 1) The charging container (such as the charging box) 2 slides into the second area T2 under the push of the driving rod of the first linear motor 6 and weighs the unfilled container 2 through the first weighing device 3 weight (W 0 );

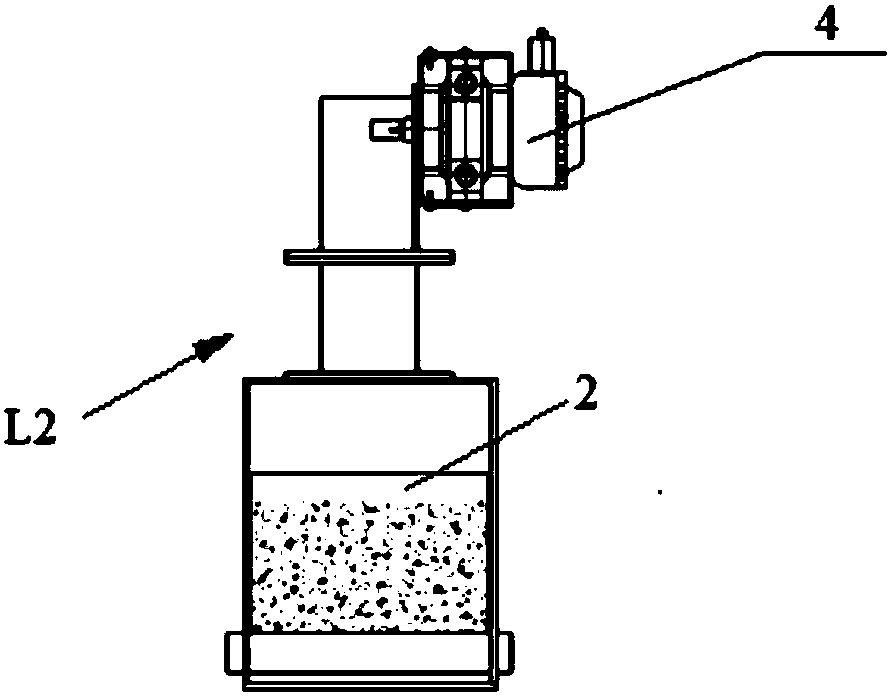

[0104] 2) extract (for example, use the manipulator 10 or the sampling driving device 11 to extract) material samples from the mixed materials from the bulk material mixing process and add the samples of the materials to be tested into the hopper 1, and the grabbed samples pass through The hopper 1 is dropped into a charging container (for example a charging box) 2 that has entered into the second zone T2;

[0105] 3) ...

Embodiment 1

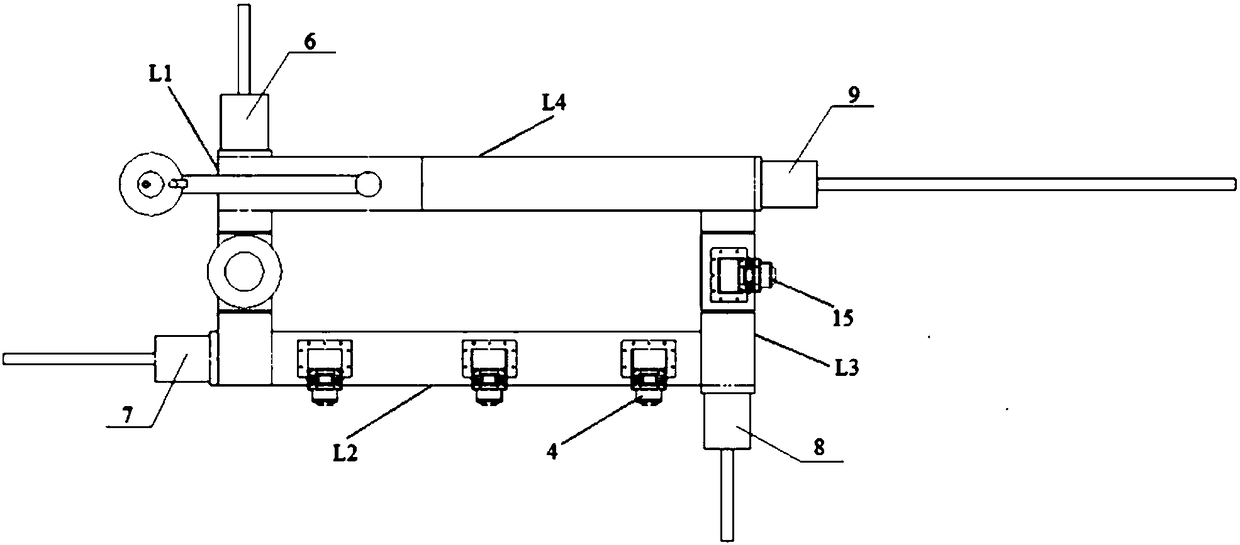

[0129] Such as figure 1 , an on-line moisture detection device for bulk materials, the device includes four slideways, namely the first slideway L1, the second slideway L2, the third slideway L3 and the fourth slideway L4, the four slideways are sequentially Connected from end to end to form a square closed loop. On the chute of the closed circuit placed 8 magazines Kata 2. The first slide L1 is the feeding area, the second slide L2 is the microwave drying area, the third slide L3 is the detection area, and the fourth slide L4 is the discharge area.

[0130] Such as figure 2 , the first slideway L1 is divided into the first area T1, the second area T2 and the third area T3 as the station for feeding and first weighing. Wherein the third area T3 links to each other with the second slideway L2, and the first slideway L1 is provided with the first linear motor 6 at the end that links to each other with the fourth slideway L4, and the driving rod of the first linear motor 6 (...

Embodiment 2

[0136] Repeat embodiment 1, only the sampling equipment of this device is changed into sampling driving device 11, and sampling driving device 11 comprises the sampling plane 1101 that is positioned at front end, the sampling pipeline 1102 that is positioned at middle end and the sampling driving structure 1103 that is positioned at end, and sampling driving device 11 uses Grab the material and send it to hopper 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com