Easy-to-install bracket for inspection of auto parts

A technology for auto parts and inspection brackets, which is applied in vehicle testing, mechanical component testing, and machine/structural component testing. Convenient and stable clamping, convenient clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

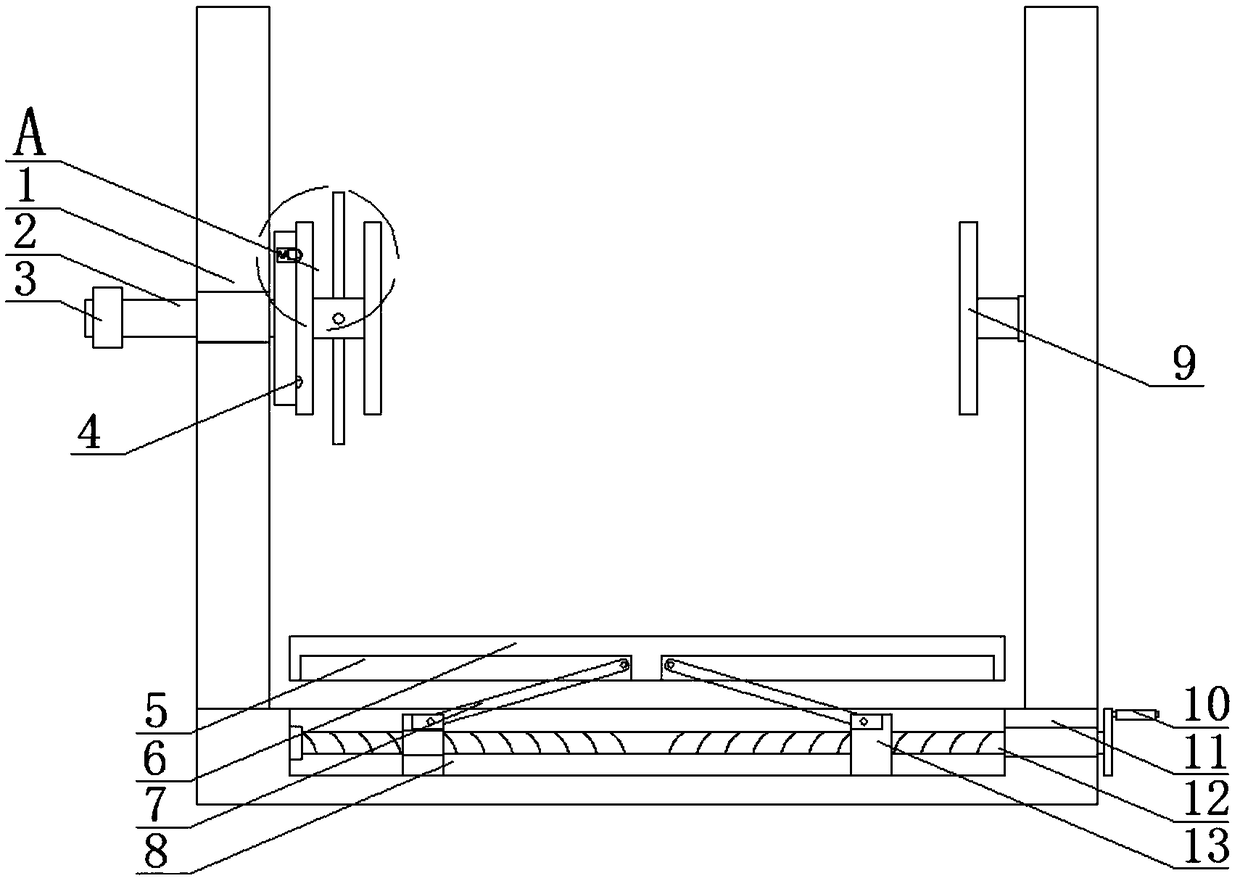

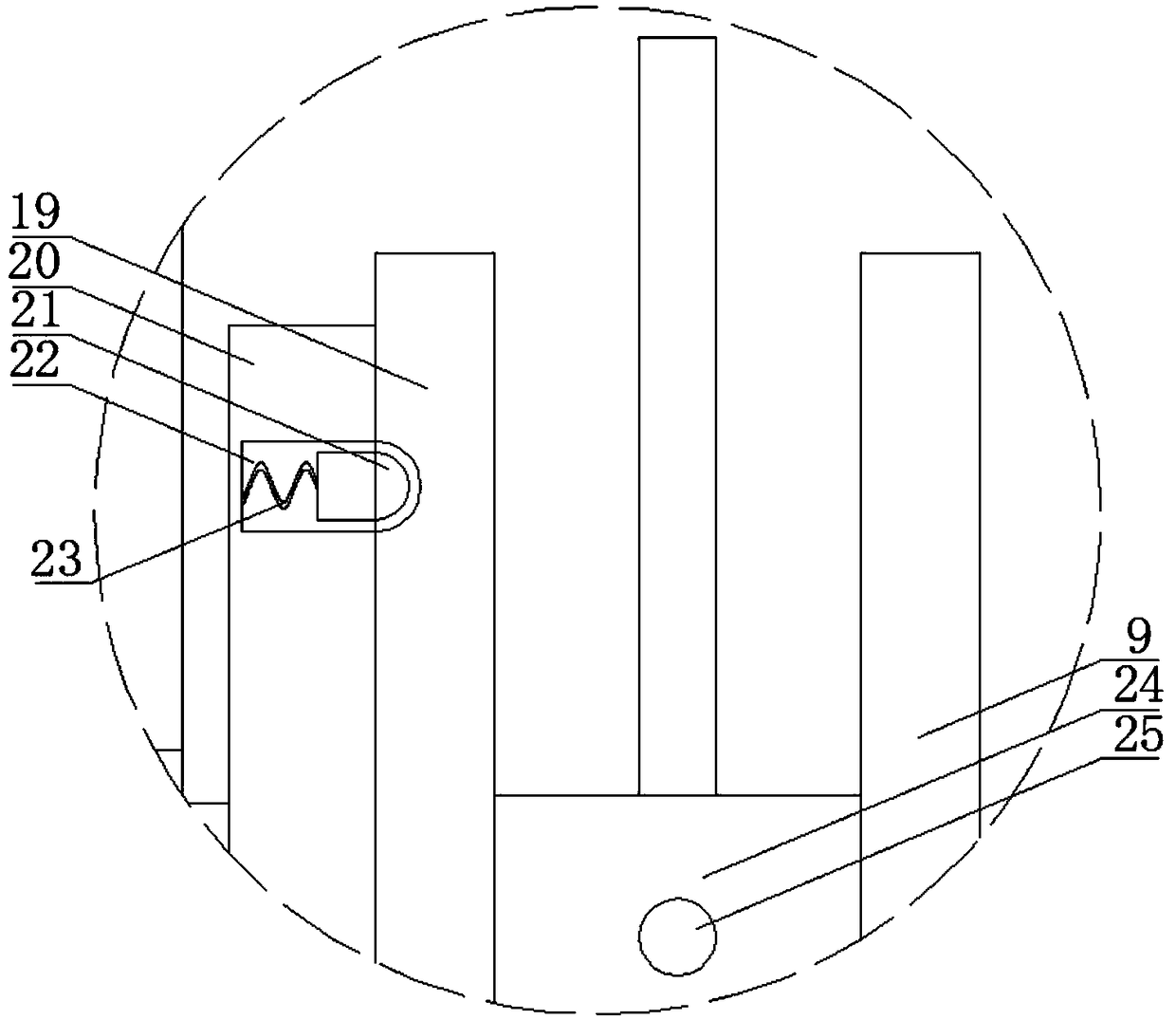

[0026] refer to figure 1 , 2 , 3, 4, a stamping machine for auto parts with cleaning equipment, including a base 11, vertical plates 1 are fixed on both sides of the upper end of the base 11, and a moving rod 2 is slidingly sleeved on one of the vertical plates 1 for easy movement Rod 2 moves on this vertical board 1, and one end of moving rod 2 is fixed with cross bar 3, and one side of this vertical board 1 is fixed with dividing plate 17, and the dividing plate 17 is slidably sleeved with polished rod 15, facilitates polished rod 15 in the partition. Move on the plate 17, and one end of the cross bar 3 is fixed on one end of the polished rod 15, and the polished rod 15 and the moving rod 2 move synchronously through the cross bar 3, thereby facilitating adjustment;

[0027] The polished rod 15 is sleeved with a first spring 14, one end of the first spring 14 is fixed on one side of the dividing plate 17, and the other end of the first spring 14 is fixed on an end of the cr...

Embodiment 2

[0031] refer to figure 1 , 2 , 3, 4, a stamping machine for auto parts with cleaning equipment, including a base 11, vertical plates 1 are fixed on both sides of the upper end of the base 11, and a moving rod 2 is slidingly sleeved on one of the vertical plates 1 for easy movement Rod 2 moves on this vertical board 1, and one end of moving rod 2 is fixed with cross bar 3, and one side of this vertical board 1 is fixed with dividing plate 17, and the dividing plate 17 is slidably sleeved with polished rod 15, facilitates polished rod 15 in the partition. Move on the plate 17, and one end of the cross bar 3 is fixed on one end of the polished rod 15, and the polished rod 15 and the moving rod 2 move synchronously through the cross bar 3, thereby facilitating adjustment;

[0032] The polished rod 15 is sleeved with a first spring 14, one end of the first spring 14 is fixed on one side of the dividing plate 17, and the other end of the first spring 14 is fixed on an end of the cr...

Embodiment 3

[0037] refer to figure 1 , 2 , 3, 4, a stamping machine for auto parts with cleaning equipment, including a base 11, vertical plates 1 are fixed on both sides of the upper end of the base 11, and a moving rod 2 is slidingly sleeved on one of the vertical plates 1 for easy movement Rod 2 moves on this vertical board 1, and one end of moving rod 2 is fixed with cross bar 3, and one side of this vertical board 1 is fixed with dividing plate 17, and the dividing plate 17 is slidably sleeved with polished rod 15, facilitates polished rod 15 in the partition. Move on the plate 17, and one end of the cross bar 3 is fixed on one end of the polished rod 15, and the polished rod 15 and the moving rod 2 move synchronously through the cross bar 3, thereby facilitating adjustment;

[0038] The polished rod 15 is sleeved with a first spring 14, one end of the first spring 14 is fixed on one side of the dividing plate 17, and the other end of the first spring 14 is fixed on an end of the cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com