A method for preventing and controlling rockburst in near-vertical coal seams by deep and shallow hole depressurization blasting

A technology of pressure relief blasting and rock bursting, applied in blasting, ground mining, earthwork drilling and other directions, can solve the problems of impact disaster, abnormal stress transfer, difficult pressure relief effect, etc., to reduce stress concentration and reduce impact risk. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0025] The invention provides a method for preventing and controlling rockburst in a near vertical coal seam by deep and shallow hole pressure relief blasting.

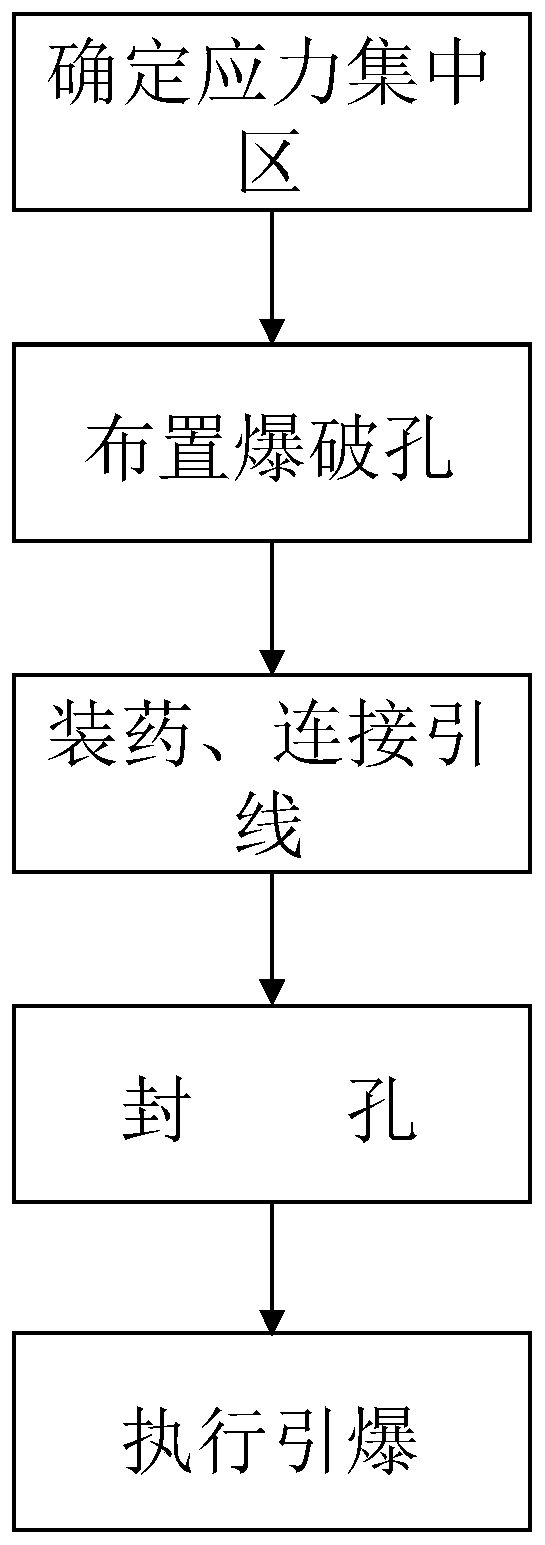

[0026] Such as figure 1 As shown, the specific steps of the method are:

[0027] (1) Determine the stress concentration area according to the monitoring data;

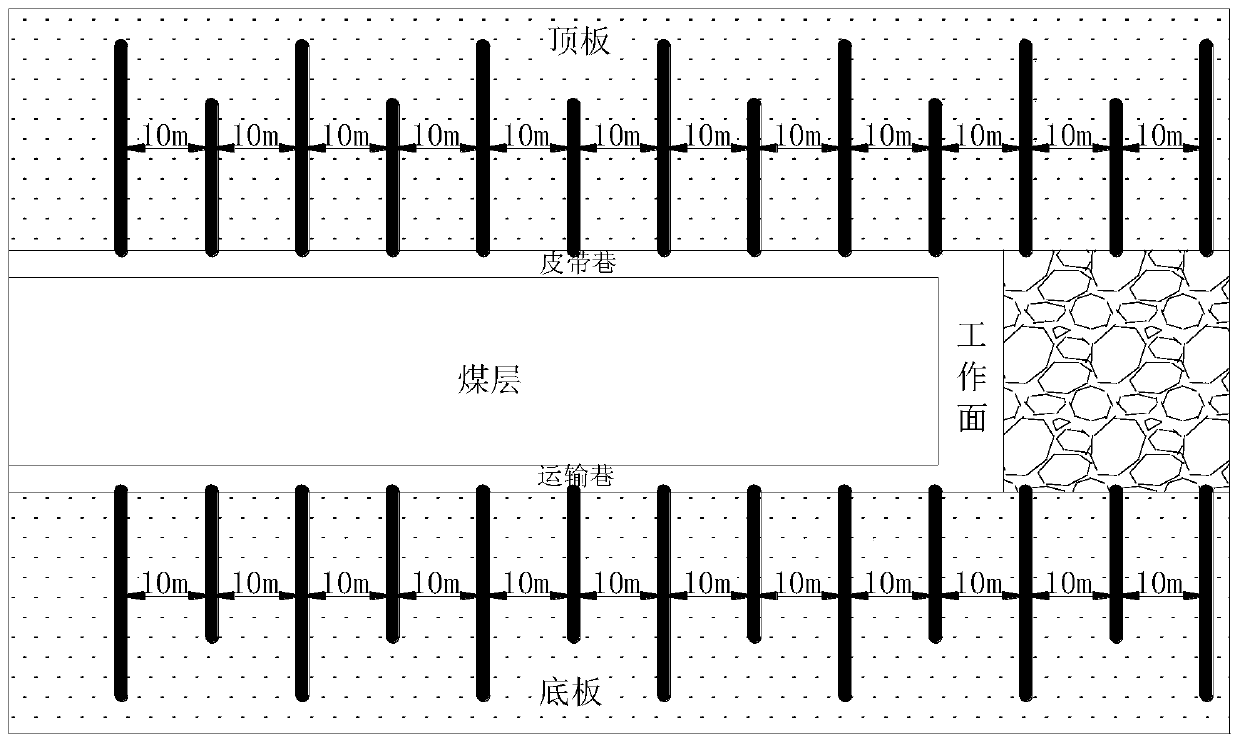

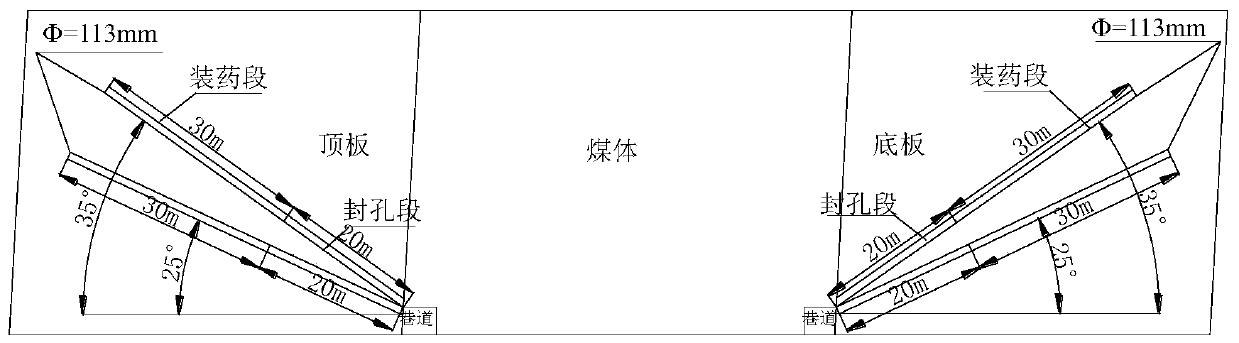

[0028] (2) Multiple rows of deep blastholes and shallow blastholes are alternately arranged on the roof and bottom of the area to be depressurized. Among them, there are 2 deep blastholes in each row and 3 shallow blastholes in each row with a row spacing of 20m. The direction is fan-shaped distribution;

[0029] (3) Charge powder, connect leads and seal holes after drilling;

[0030] (4) Detonation is performed with a detonator.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com