Radical ion modified wet process high stripping polyurethane resin for synthetic leather and preparation method thereof

A technology of polyurethane resin and base modification, which is applied to the field of wet high peeling polyurethane resin for ion-based modified synthetic leather and its preparation, can solve the problems of high residual DMF, slow cohesion and production speed, etc., so as to improve production efficiency, Fast agglomeration, favorable effect for replacement and cleaning processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] A kind of preparation method of ion-based modified synthetic leather wet process high peeling polyurethane resin, comprises the following steps:

[0035] (1), adding the polyester diol of adipic acid series and an appropriate amount of small molecule dibasic alcohol chain extender and antioxidant to form the polyol compound in the solvent to form a solution with a solid content of 45-50%, The small molecule glycol chain extender accounts for 14%-18% of the total weight of the chain extender;

[0036] (2) Stir the solution obtained in step (1) evenly, then add part of diisocyanate and catalyst, so that the molar ratio of isocyanate in diisocyanate to active hydrogen in the system is 1.0-1.05:1. React at 75-85°C for 1-2h, control the viscosity of prepolymerization by controlling the reaction time, and control the viscosity at 30-40Pas / 75°C; the molar ratio of the isocyanate in the diisocyanate to the active hydrogen in the system is 1.0-1.05:1, part of the diisocyanate h...

Embodiment 1

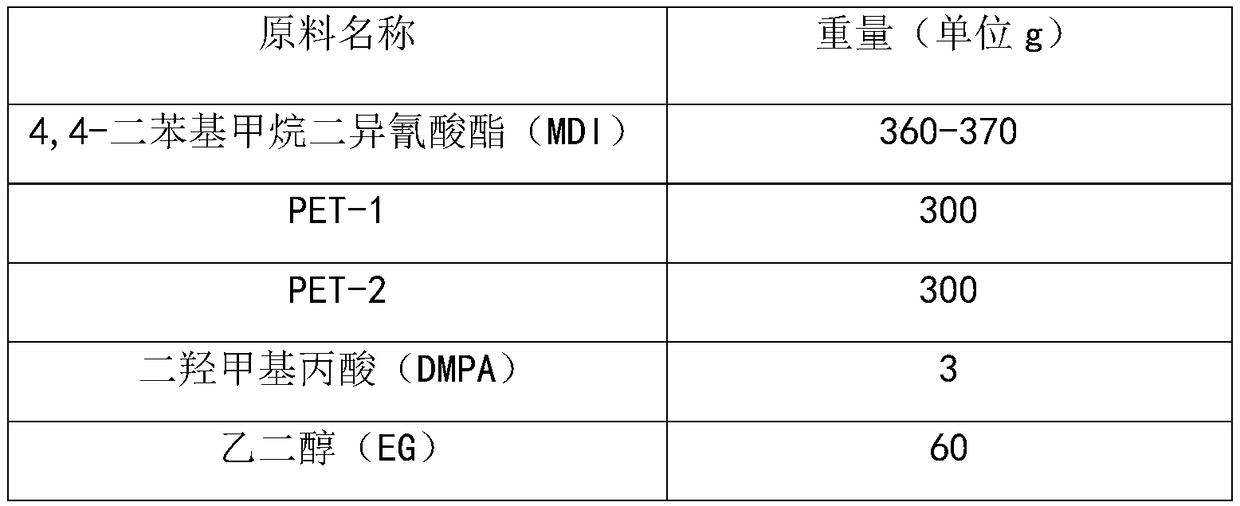

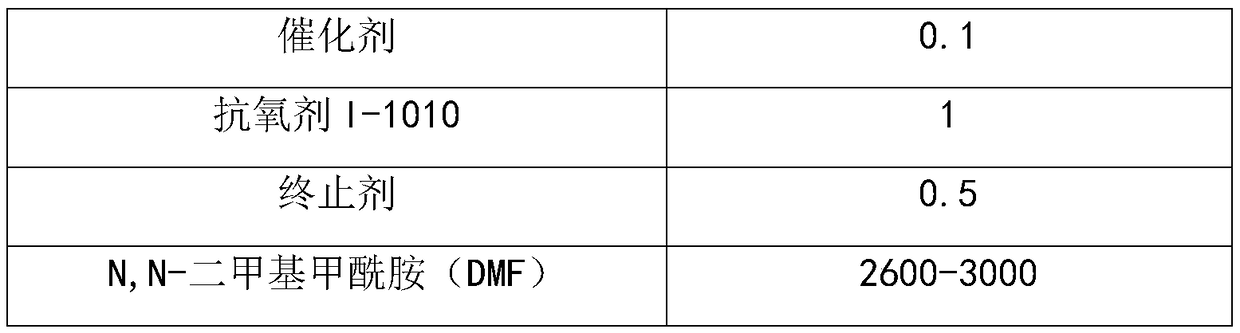

[0039] A kind of ion-based modified synthetic leather wet-process high-stripping polyurethane resin is mainly prepared from the components shown in Table 1:

[0040] Table 1 Example 1 component table

[0041]

[0042]

[0043] Among them, the above-mentioned PET-1 and PET-2 are polyester diols with molecular weights of 1000 and 2000 respectively, which are prepared by the reaction of adipic acid, ethylene glycol and 1,4-butanediol. Hefei Amway Polyurethane New Material Co., Ltd.; dimethylolpropionic acid (DMPA) is produced by GEO Specialty Chemicals Company of the United States. The above-mentioned catalyst is organic bismuth; the reaction terminator is methanol.

[0044] An ion-based modified synthetic leather wet-process high-stripping polyurethane resin specifically includes the following steps:

[0045] (1), 300g PET-2, 300g PET-1, 10g EG and 1g antioxidant I-1010 were added to 740g DMF solvent to form a solution with a solid content of 45-50%;

[0046](2), after t...

Embodiment 2

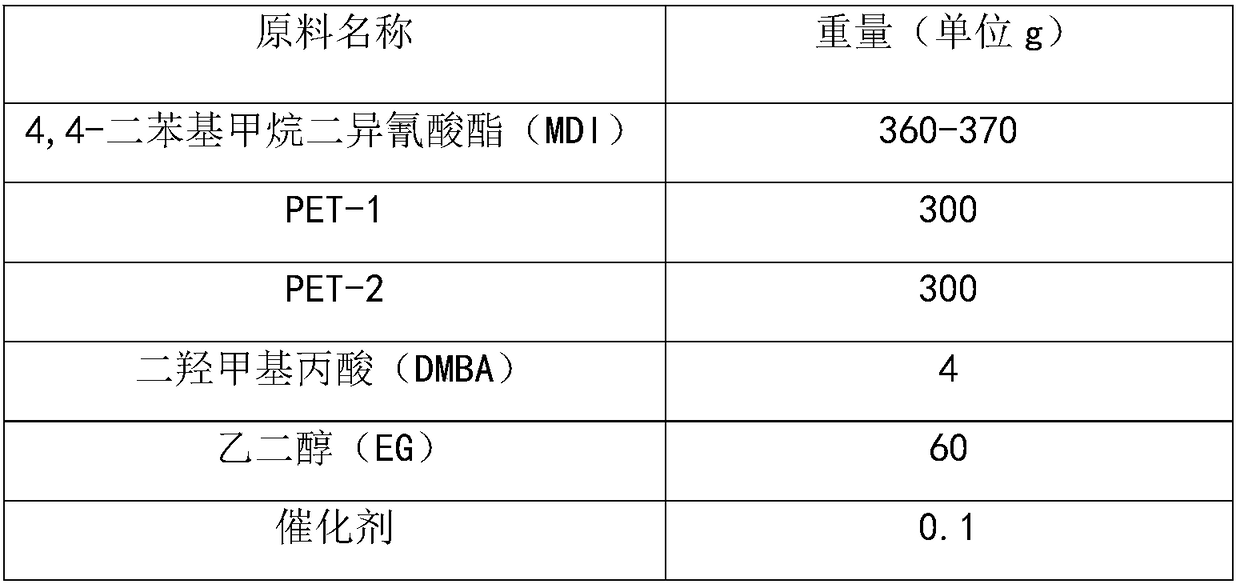

[0049] A kind of ion-based modified synthetic leather wet-process high-stripping polyurethane resin is mainly prepared from the components shown in Table 2:

[0050] Table 2 Example 2 component table

[0051]

[0052]

[0053] Among them, the above-mentioned PET-1 and PET-2 are polyester diols with molecular weights of 1000 and 2000 respectively, which are prepared by the reaction of adipic acid, ethylene glycol and 1,4-butanediol. Hefei Amway Polyurethane New Material Co., Ltd.; Dimethylolpropionic acid (DMBA) is produced by Jiangxi Nancheng Hongdu Chemical Technology Development Co., Ltd. The above-mentioned catalyst is organic bismuth; the reaction terminator is methanol.

[0054] An ion-based modified synthetic leather wet-process high-stripping polyurethane resin specifically includes the following steps:

[0055] (1), 300g PET-2, 300g PET-1, 10g EG and 1g antioxidant I-1010 were added to 740g DMF solvent to form a solution with a solid content of 45-50%;

[0056]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com