Method for extracting cholest-3,5-dien-7-one from Aspergillus niger by separation

A technology of Aspergillus niger and cholesteric, which is applied in the field of extracting cholestan-3,5-dien-7-one, can solve the problems of no separation and extraction, and achieve the effects of reliable source, easy cultivation and preservation, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

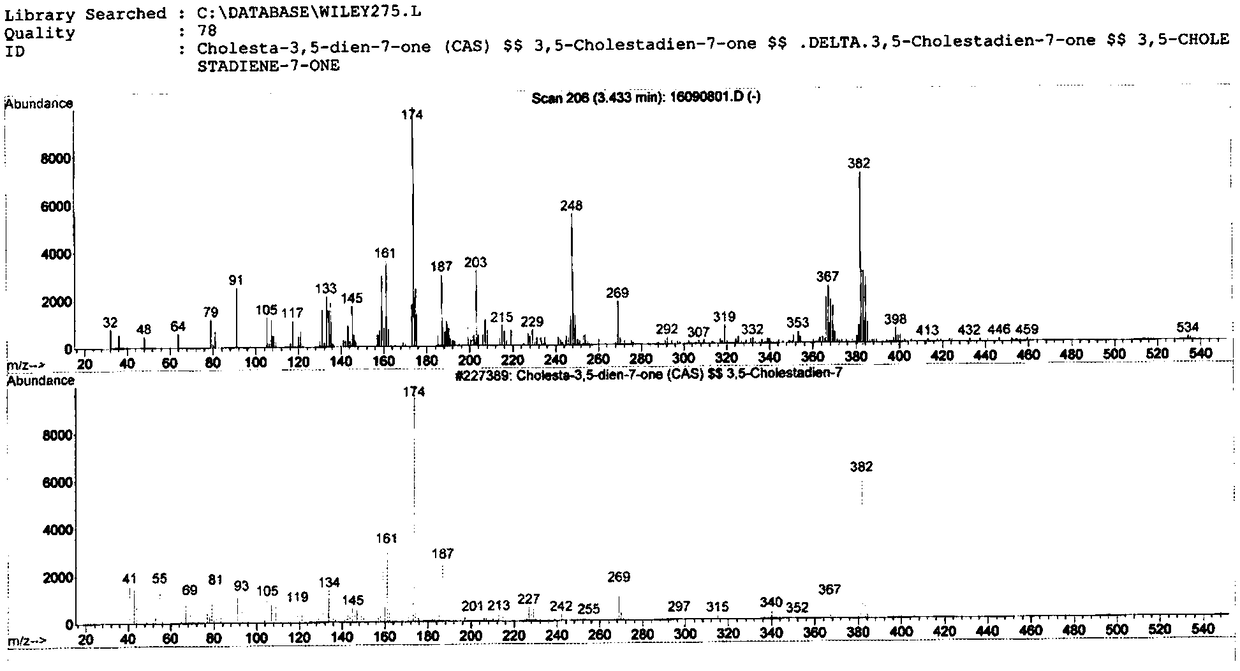

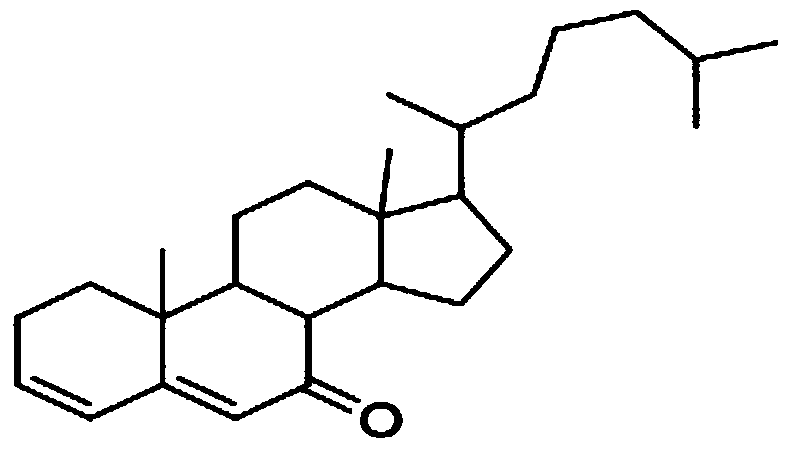

Image

Examples

Embodiment 1

[0033] Embodiment 1: A method for separating and extracting cholesta-3,5-dien-7-one by using Aspergillus niger, the steps are as follows:

[0034] 1) Preparation of extract: put the fermented mycelia of Aspergillus niger in a blast drying oven, bake at 55°C until constant weight, grind the powder, pass through a 60-mesh sieve to obtain the fungal powder, and use acetone to mix the fungal powder with a ratio of 1:4. Weight ratio, at a temperature of 75°C and a pressure of 0.5MPa, extract 3 times to obtain the Aspergillus niger extract, and the time is 3 hours each time, and the extract is rotated at a temperature of 50°C and a pressure of 0.05MPa using a rotary evaporator. Evaporate until the organic solvent evaporates to dryness to obtain the extract;

[0035] 2) Silica gel column chromatography: use petroleum ether to wet-pack the column to obtain a silica gel chromatography column, dissolve the extract in step (1) with acetone solvent and mix the sample with silica gel with ...

Embodiment 2

[0039] Example 2: A method for separating and extracting cholesta-3,5-dien-7-one by using Aspergillus niger, the steps are as follows:

[0040]1) Preparation of extract: put the fermented mycelia of Aspergillus niger in a blast drying oven, bake at 55°C until constant weight, grind the powder, pass through a 60-mesh sieve to obtain the fungal powder, and use acetone to mix the fungal powder with a ratio of 1:4. Weight ratio, extract 3 times at a temperature of 50°C and a pressure of 0MPa to obtain an Aspergillus niger extract, each time for 3h, and use a rotary evaporator to rotate the extract at a temperature of 40°C and a pressure of 0.04MPa When the organic solvent is evaporated to dryness, the extract is obtained;

[0041] 2) Silica gel column chromatography: use petroleum ether to wet-pack the column to obtain a silica gel chromatography column, dissolve the extract in step (1) with acetone solvent and mix the sample with silica gel with a size of 200 mesh, evaporate the ...

Embodiment 3

[0045] Example 3: A method for separating and extracting cholesta-3,5-dien-7-one using Aspergillus niger, the steps are as follows:

[0046] 1) Preparation of extract: put the fermented mycelia of Aspergillus niger in a blast drying oven, bake at 55°C until constant weight, grind the powder, pass through a 60-mesh sieve to obtain the fungal powder, and use acetone to mix the fungal powder with a ratio of 1:4. Weight ratio, at a temperature of 100°C and a pressure of 1.0MPa, extract 3 times to obtain the Aspergillus niger extract, and the time is 3 hours each time, and the extract is rotated at a temperature of 60°C and a pressure of 0.06MPa using a rotary evaporator. Evaporate until the organic solvent evaporates to dryness to obtain the extract;

[0047] 2) Silica gel column chromatography: use petroleum ether to wet-pack the column to obtain a silica gel chromatography column, dissolve the extract in step (1) with acetone solvent and mix the sample with silica gel with a siz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com