Preparation method and application of hierarchical porous ZSM-5 molecular sieve

A ZSM-5, molecular sieve technology, applied in molecular sieve catalysts, including molecular sieve catalysts, chemical instruments and methods, etc., can solve the problem of restricting the industrial production and application of multi-level porous ZSM-5 molecular sieves, discharging a large amount of synthetic waste liquid, and single-pot synthesis. problems such as low efficiency, to achieve good industrial application prospects, significant economic and environmental benefits, and the effect of improving synthesis efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

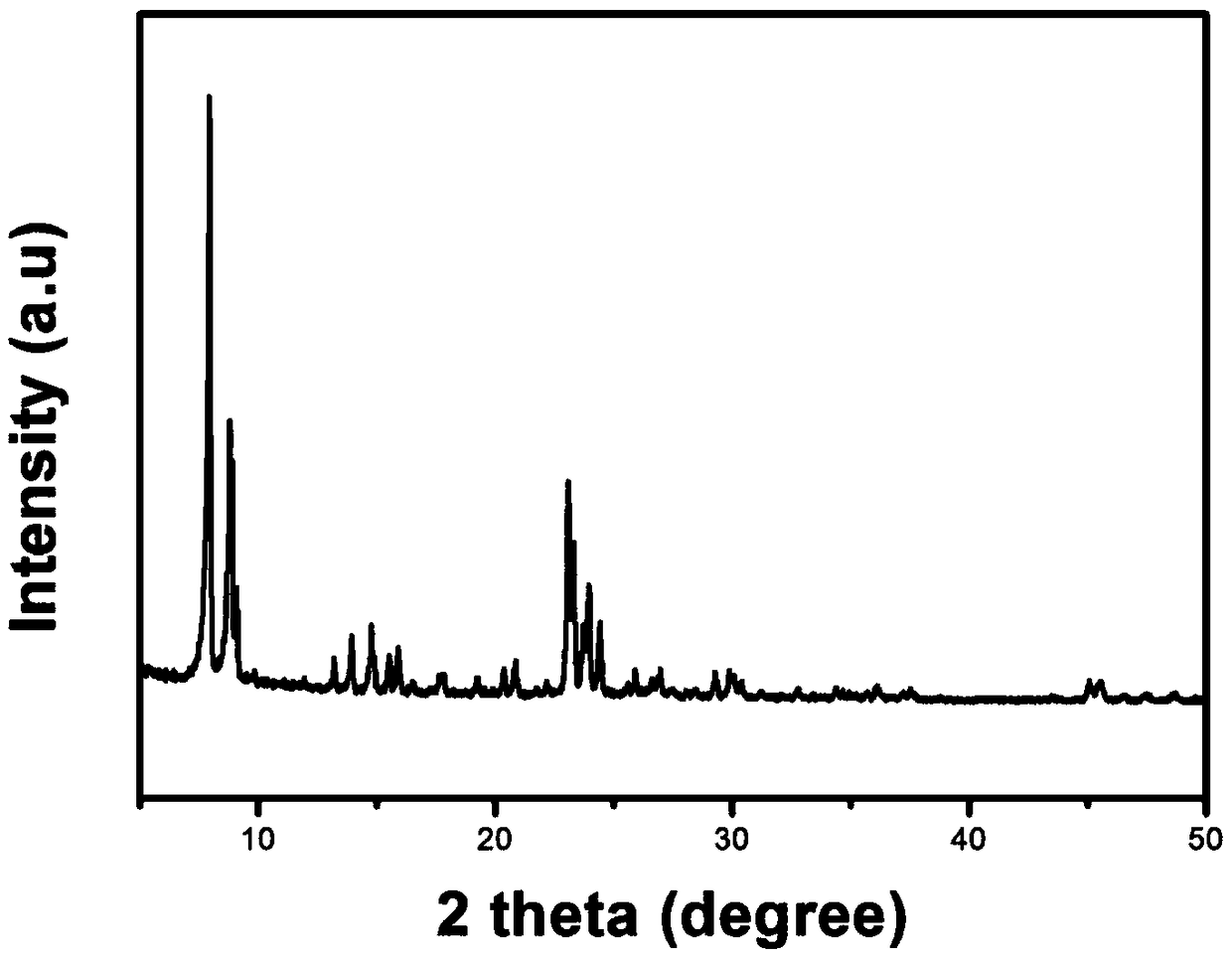

Embodiment 1

[0033]A preparation method of a multi-stage pore ZSM-5 molecular sieve: 3.2 g of surfactant cetyltrimethylammonium bromide is dissolved in 40.0 g of deionized water, and stirred at room temperature until completely dissolved to form a mixed solution A; Then add 0.2g of aluminum isopropoxide and 10.4g of tetraethyl orthosilicate, stir in a constant temperature water bath at 40°C for 2h to form a mixed solution B; then add 3.0g of tetrapropylammonium hydroxide dropwise to the B solution, A mixed solution is formed, and the above mixed solution is heated to 60°C and stirred in a constant temperature water bath for 24 hours for aging to form a mixture of molecular sieves to synthesize an initial sol-gel; place the above-mentioned initial sol-gel in an oven at 100°C for 24 hours to obtain a molecular sieve synthetic dry gel, dry The glue was transferred to the crystallization kettle, and the molecular sieve crystallization process was realized by steam-assisted crystallization metho...

Embodiment 2

[0036] A preparation method of a multi-stage porous ZSM-5 molecular sieve: Dissolve 2.8 g of surfactant cetyltrimethylammonium bromide in 36.0 g of deionized water, stir at room temperature until completely dissolved, and form a mixed solution A; Then add 0.4g of aluminum isopropoxide and 20.8g of tetraethyl orthosilicate, stir in a constant temperature water bath at 40°C for 2h to form a mixed solution B; then add 6.0g of tetrapropylammonium hydroxide dropwise to the B solution, A mixed solution is formed, and the above mixed solution is heated to 60°C and stirred in a constant temperature water bath for 24 hours for aging to form a mixture of molecular sieves to synthesize an initial sol-gel; place the above-mentioned initial sol-gel in an oven at 100°C for 24 hours to obtain a molecular sieve synthetic dry gel, dry The glue was transferred to the crystallization kettle, and the molecular sieve crystallization process was realized by steam-assisted crystallization method. The...

Embodiment 3

[0038] A preparation method of a multi-stage porous ZSM-5 molecular sieve: Dissolve 1.6 g of surfactant cetyltrimethylammonium bromide in 40.0 g of deionized water, stir at room temperature until completely dissolved, and form a mixed solution A; Then add 0.2g of aluminum isopropoxide and 10.4g of tetraethyl orthosilicate, stir in a constant temperature water bath at 40°C for 2h to form a mixed solution B; then add 6.0g of tetrapropylammonium hydroxide dropwise to the B solution, A mixed solution is formed, and the above mixed solution is heated to 60°C and stirred in a constant temperature water bath for 24 hours for aging to form a mixture of molecular sieves to synthesize an initial sol-gel; place the above-mentioned initial sol-gel in an oven at 100°C for 24 hours to obtain a molecular sieve synthetic dry gel, dry The glue was transferred to the crystallization kettle, and the molecular sieve crystallization process was realized by steam-assisted crystallization method. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com