Stamping device for autoclaved aerated concrete building block

A technology of aerated concrete and autoclaved sand, applied in ceramic molding machines, manufacturing tools, etc., can solve the problems of reducing production efficiency, loss of products, time-consuming and laborious, etc., and achieve the effects of stable marking, high automatic operation and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

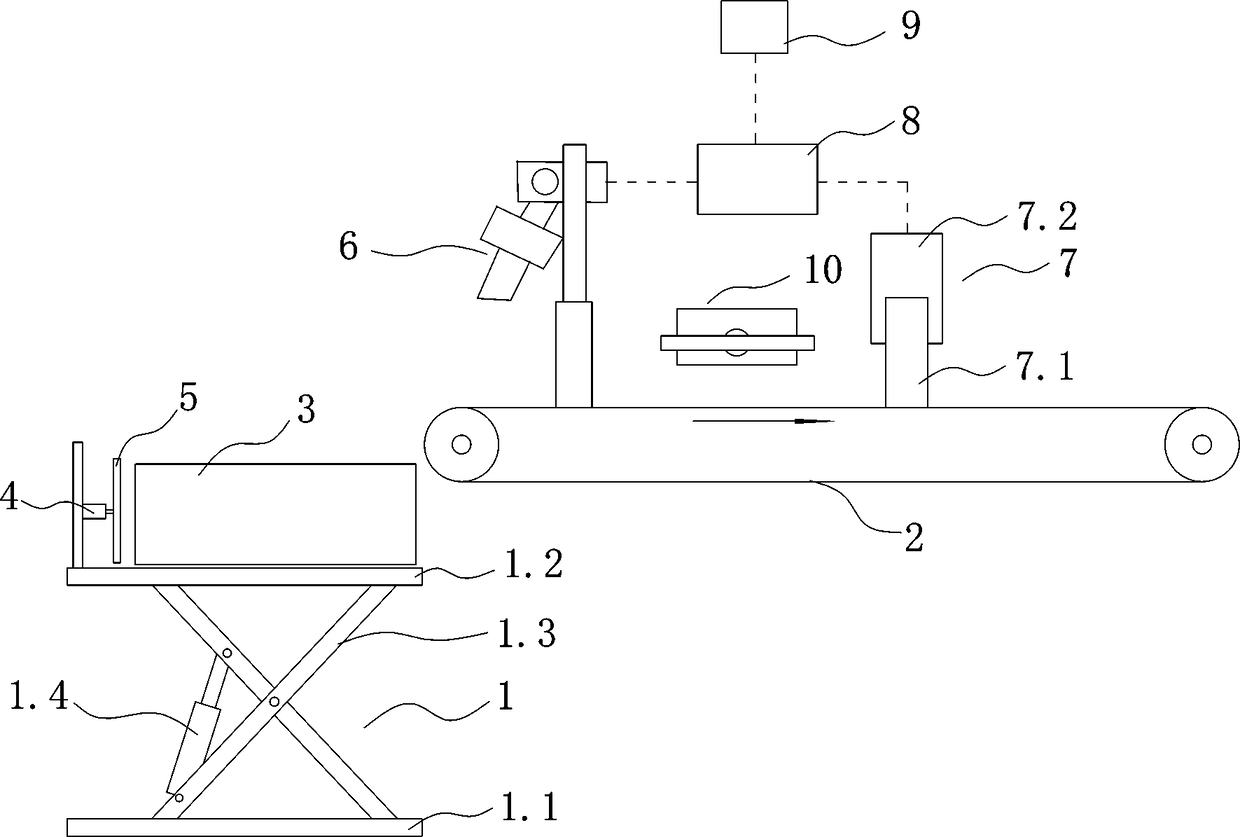

[0016] Such as Figures 1 to 2 As shown, an autoclaved sand aerated concrete block marking device includes a lifting platform 1 and a conveyor belt device 2, and the lifting platform 1 is used to lift the autoclaved sand aerated concrete block 3 to the conveyor belt device 2 for transportation At the front end, the conveyor belt device 2 is used to transport the autoclaved sand aerated concrete block 3 to the marking area for marking;

[0017] The top of the lifting platform 1 is horizontally provided with a first hydraulic telescopic rod 4, the telescopic end of the first hydraulic telescopic rod 4 is vertically connected to the first push plate 5, and the front end of the conveyor belt device 2 is provided with a photoelectric sensor 6, The conveying rear end of the conveyor belt device 2 is provided with an engraving device 7 for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com