Hydraulic bulging tube with partially thickened wall thickness and forming method of hydraulic bulging tube

A hydraulic bulging and partial technology, applied in the field of hydraulic bulging of pipe fittings, can solve the problems of no local thickening of hydroformed parts, no involvement of hydraulic bulging tube design and forming methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

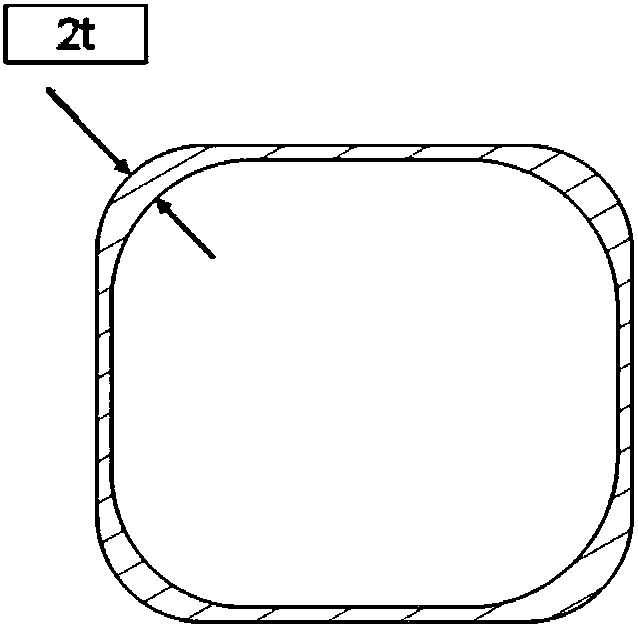

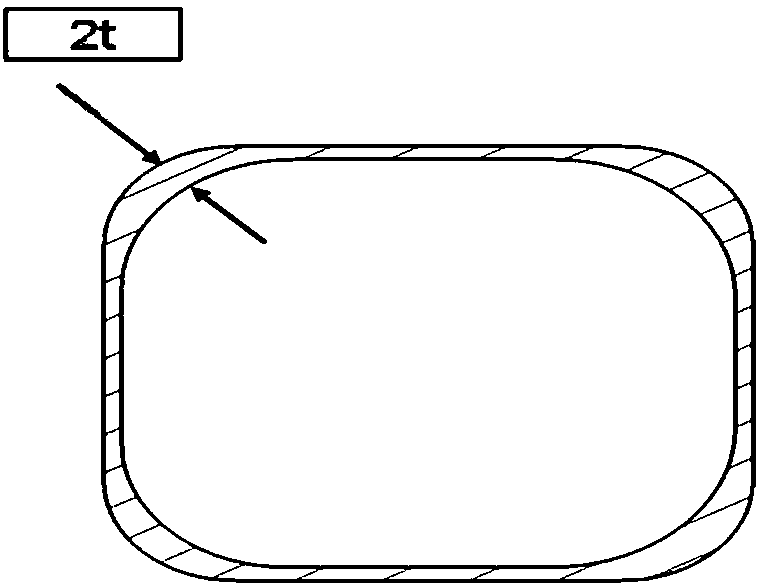

[0068] A kind of hydroforming of pipe fittings with thickened wall thickness at the R angle position of the cross section, such as Figure 1 ~ Figure 3 As shown, where t is 2.0mm, the wall thickness increases at the four R corners. Specifically, for the convenience of subsequent forming mold processing, the wall thickness increases toward the inner side of the tube. This wall thickening feature is present throughout the length of the pipe.

[0069] The subframe tube blank is as Figure 4 , Figure 5 As shown, the section of the tube blank is rectangular, which is an aluminum alloy tube of equal cross-section formed by the extrusion process, and the wall thickness thickening feature is realized through the extrusion process at the four R angle positions of the rectangular tube blank.

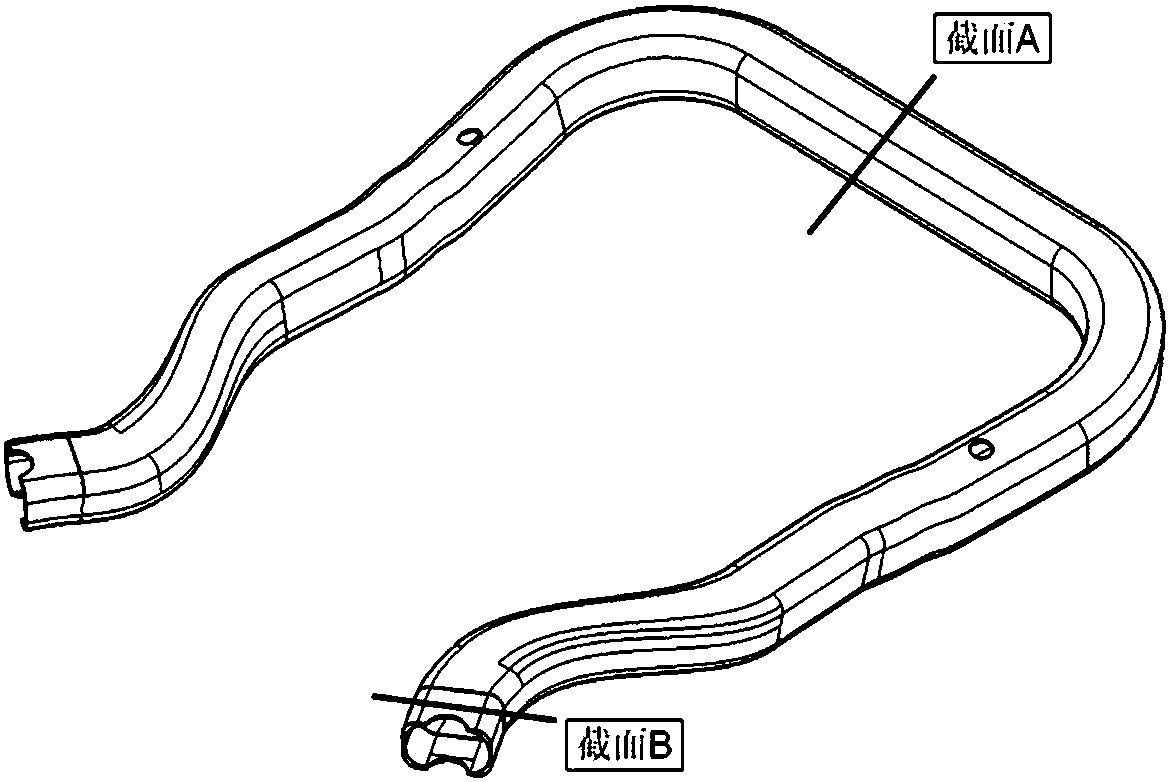

[0070] The tube blank is bent by CNC pipe bending, such as Image 6 , Figure 7 The schematic diagram after the pipe bending is shown, and the pipe bending mold is designed according to the s...

Embodiment 2

[0077] A pipe torsion beam with thickened wall thickness at the stress concentration position, such as Figure 10 ~ Figure 13 As shown, the torsion beam can be divided into three parts, the middle section is V-shaped, such as section E, the two ends are rectangular, such as section G, and the middle is a transition section.

[0078] The torsion beam is the main part of the semi-independent rear suspension. It is subjected to bending and torsion during the operation of the car, and the service conditions are harsh. Generally, the stress concentration of the torsion beam occurs at the upper part of the U-shaped groove in the transition section. In this case, for example Image 6 As shown, where t is 2.5mm, the wall thickness at the corresponding stress concentration position is 1.5 times thicker, and gradually disappears to both sides. The wall thickness thickening feature exists in the entire length direction of the pipe fitting, as shown in Image 6 , the corresponding positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com