Device and method for shear reinforcement of concrete box girder web

A technology of concrete box girder and reinforcement device, applied in the direction of bridge reinforcement, bridge, bridge construction, etc., can solve the problems of high stress, insufficient shear bearing capacity, and inclined cracks in the web of concrete box girder, so as to achieve little increase in self-weight. , the reinforcement effect is good, and the effect of reducing the loss of vertical prestress (8)

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following is only one example of the present invention, which can also be used to strengthen other types of box girder webs. Any modification, alteration or equivalent transformation of the above examples according to the technical essence of the present invention shall fall within the protection scope of the technical solution of the present invention.

[0032] The present invention will be further described below in conjunction with the drawings and embodiments.

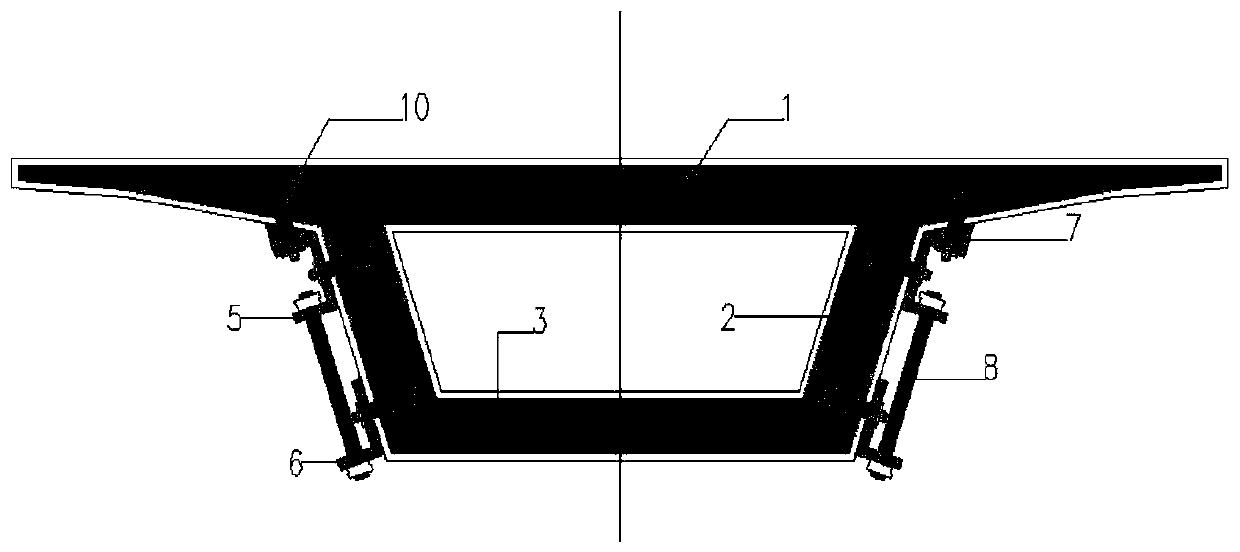

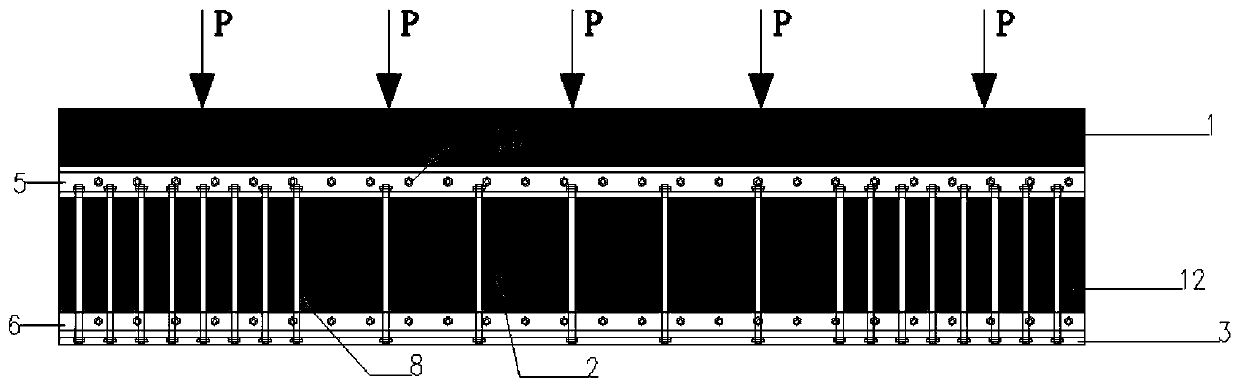

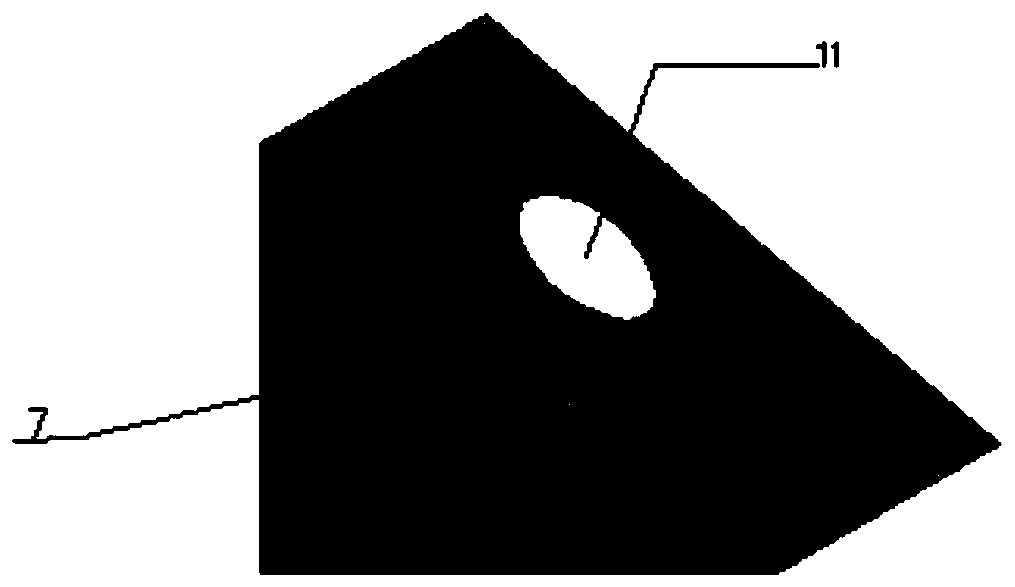

[0033] The box girder in this embodiment is a concrete box girder without ribs, such as figure 1 Including top plate (1), web (2), bottom plate (3). It is characterized in that the reinforcement device is such as Figure 4 Part of the detailed drawing is mainly composed of channel steel (5), L-shaped steel (6), vertical prestressed tendons (8), wedge-shaped steel pads (7), and anti-corrosion coating (12) on the outside of the web. The channel steel is horizontally fixed at the junction of the upper end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com