A kind of supported catalyst and its preparation method and application and Fischer-Tropsch synthesis method

A supported catalyst, Fischer-Tropsch synthesis technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] According to another aspect of the present invention, the present invention also provides a kind of preparation method of supported catalyst, and this preparation method comprises the following steps:

[0028] (1) Use the first metal component M containing at least one non-noble metal selected from Group VIII 1 The solution of the compound impregnated the support, and then the impregnated support was sequentially dried, roasted or not roasted, and reduced to activate;

[0029] (2) Under a reducing or inert atmosphere, the product obtained in step (1) is impregnated with a solution containing a high-boiling organic matter and then heat-treated to obtain a carbon-containing catalyst precursor;

[0030] (3) impregnating the carbon-containing catalyst precursor obtained in step (2) with a solution containing a compound selected from VIB and / or a second metal component of Group VIIB in a reducing atmosphere, drying and optionally calcining, to obtain The supported catalyst....

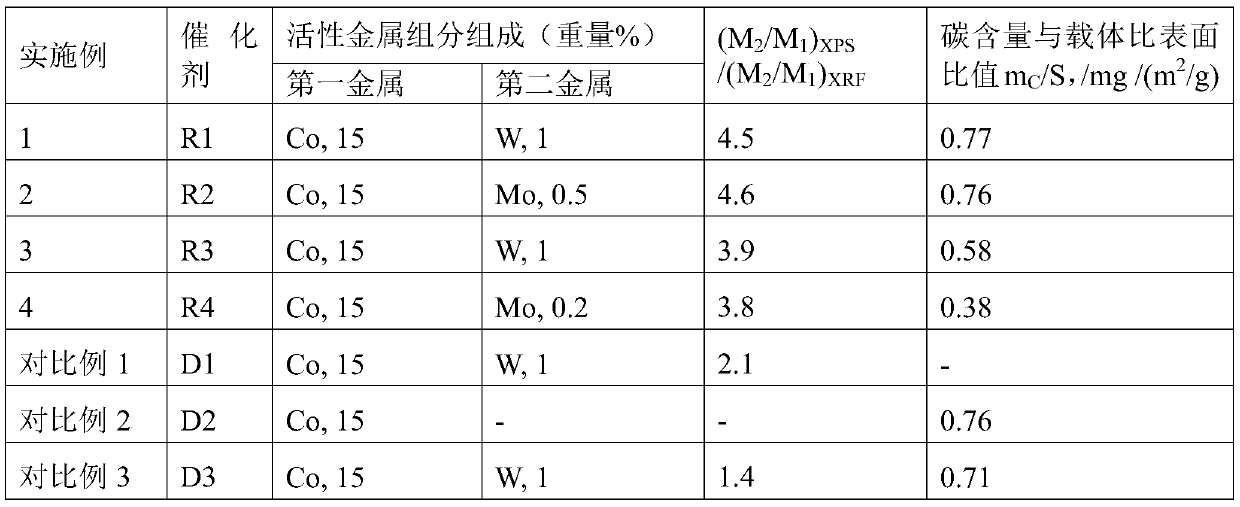

Embodiment 1

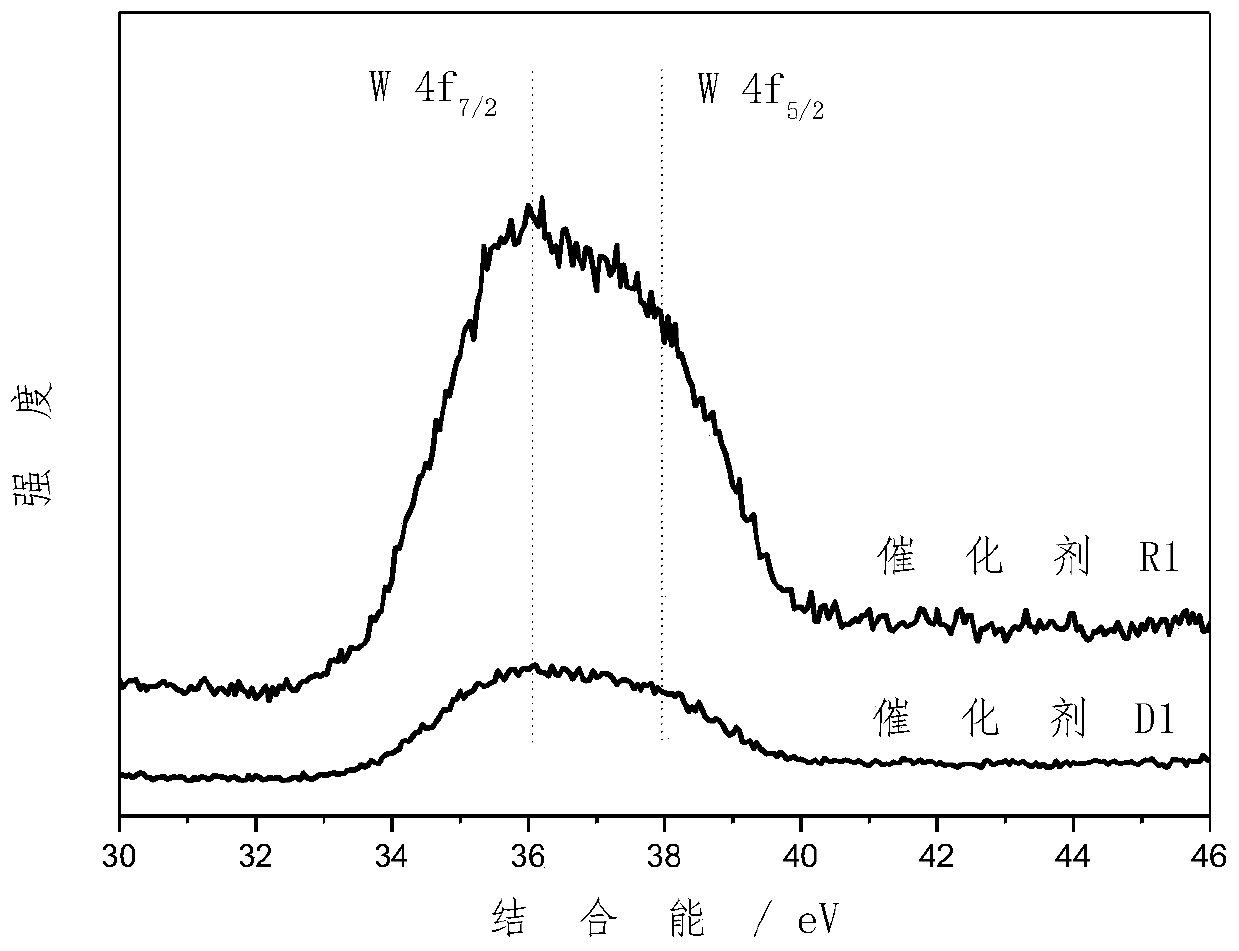

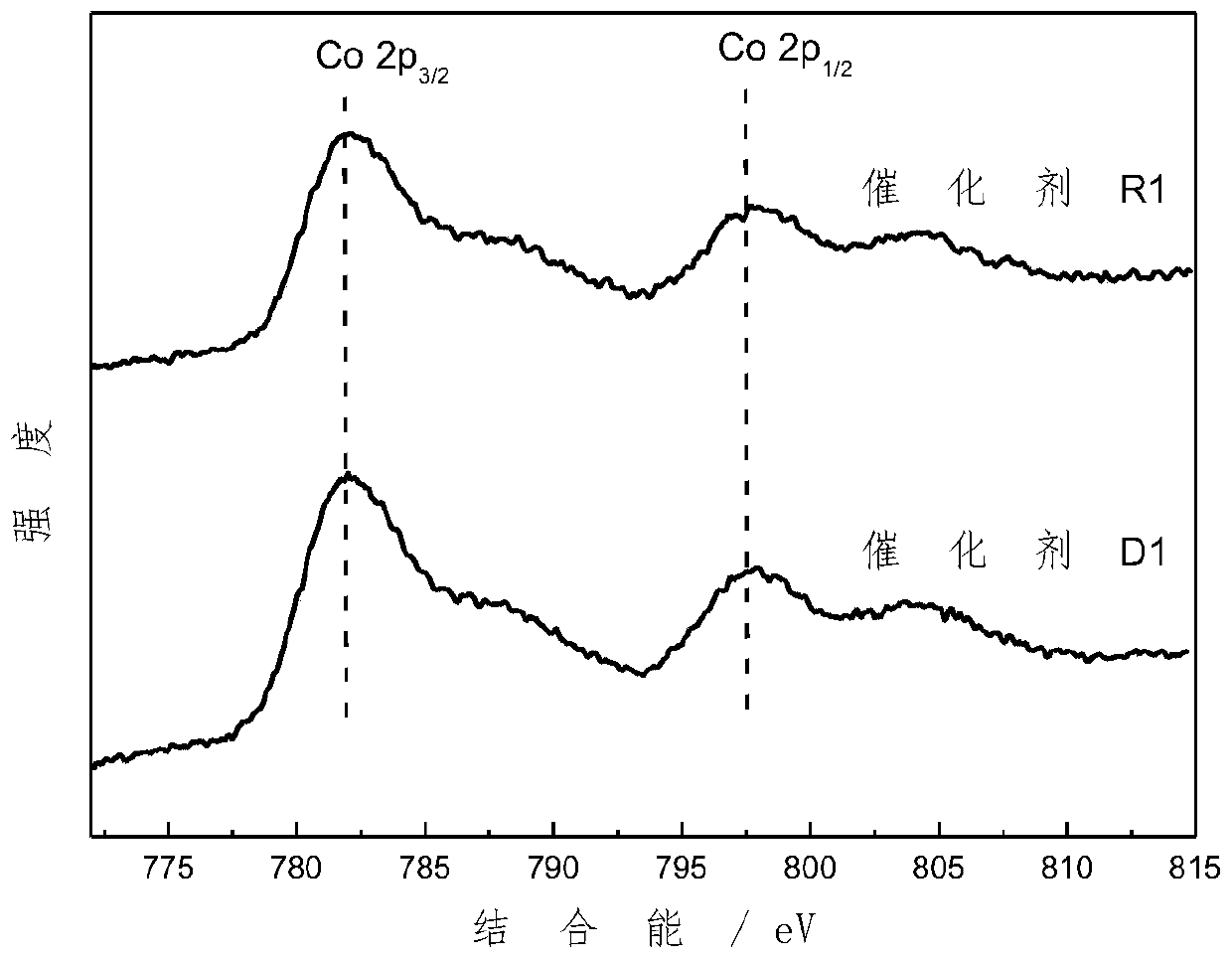

[0054] (1) Catalyst preparation and characterization

[0055] According to the required metal salt content of equal-volume impregnation method, 36.1 milliliters of cobalt nitrate containing 208 grams per liter of cobalt and 1.38 grams per liter of platinum and the impregnation solution of platinum dichlorotetraammine were prepared. Decant the impregnation solution to 42.5 g SiO 2 Carrier (Fuji Silicon Co., Ltd., Japan, average particle size 40-80 microns), stirred at 20°C for 4 hours, dried at 120°C, calcined at 400°C for 4 hours, hydrogen reduction at 400°C for 4 hours, hydrogen pressure of 0.1 MPa. After reduction, it was lowered to room temperature, and 36.1 ml of 14.5 g / L sucrose aqueous solution was added under a hydrogen atmosphere. After standing for 2 hours, it was dried at 120°C and then heated at 500°C for dehydration and carbonization. Cool down to room temperature, and add 55.1 ml of ammonium metatungstate aqueous solution containing 9.07 g / L tungsten under a hyd...

Embodiment 2

[0077] (1) Catalyst preparation and characterization

[0078] According to the required metal salt content of equal-volume impregnation method, 36.1 milliliters of cobalt nitrate containing 208 grams per liter of cobalt and 1.38 grams per liter of platinum and the impregnation solution of platinum dichlorotetraammine were prepared. Decant the impregnation solution to 42.5 g SiO 2 Carrier (Fuji Silicon Co., Ltd., Japan, average particle size 40-80 microns), stirred at 20°C for 4 hours, dried at 120°C, calcined at 400°C for 4 hours, hydrogen reduction at 400°C for 4 hours, hydrogen pressure of 0.1 MPa. After reduction, it was lowered to room temperature, and 36.1 ml of 15.3 g / L glucose aqueous solution was added under a hydrogen atmosphere, and after standing for 2 hours, it was dried at 120°C and then heated at 500°C for dehydration and carbonization. Cool down to room temperature, and add 55.1 ml of ammonium molybdate aqueous solution containing 4.54 g / L of molybdenum under ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com