A Microchannel Radiator with Temperature Homogenization

A micro-channel and homogenization technology, which is applied in the direction of cooling/ventilation/heating transformation, electrical components, electrical equipment structural parts, etc., can solve the problems of uneven flow, large temperature micro-channel pressure drop, etc., to improve heat dissipation performance, Good temperature uniformity and reduced flow length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

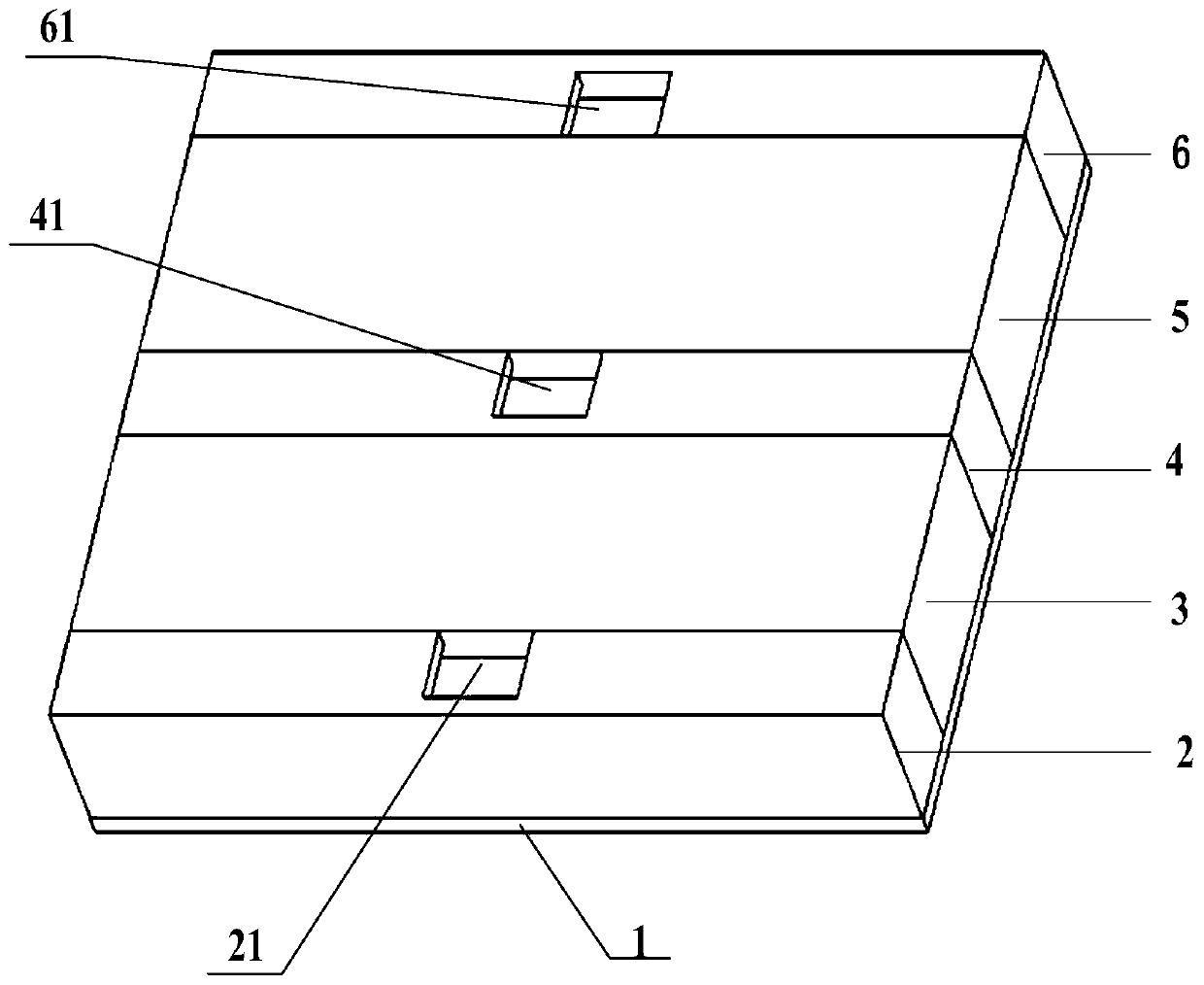

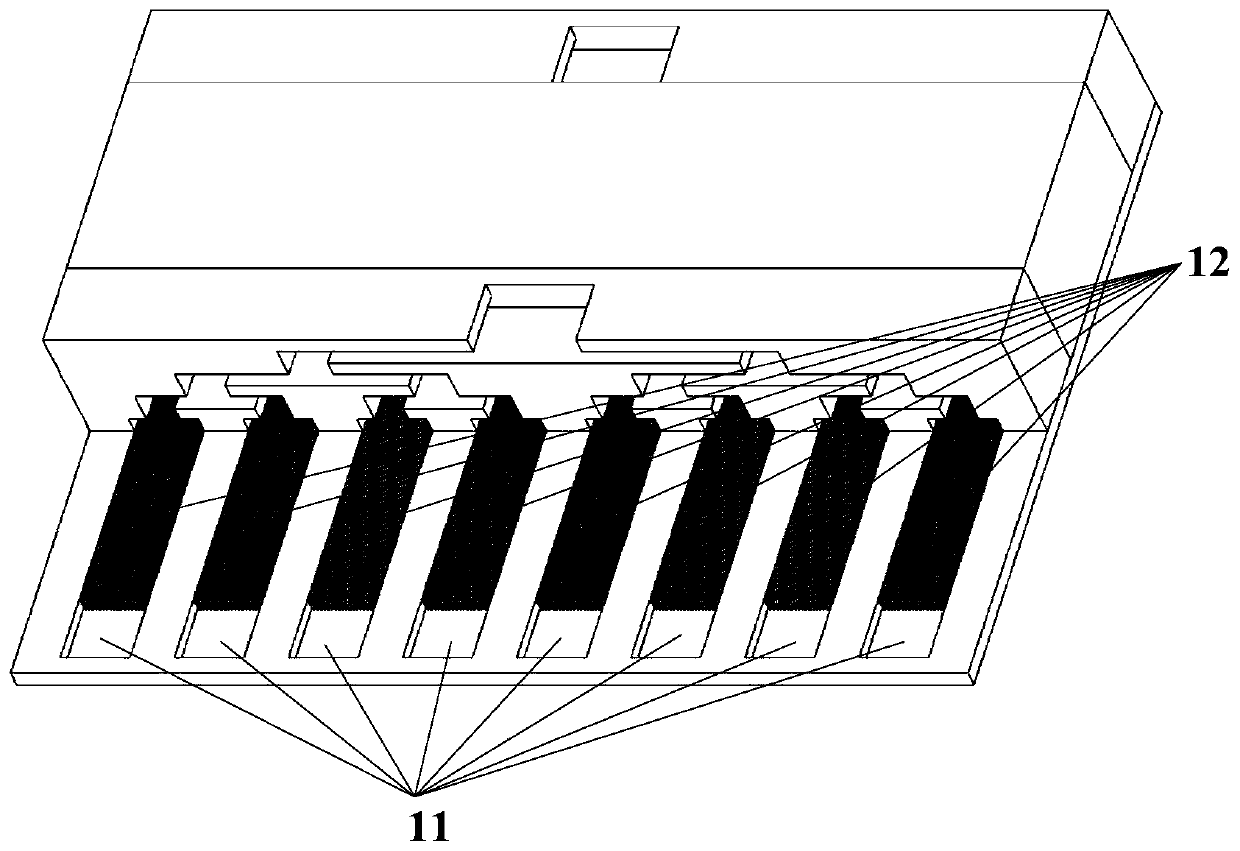

[0031] refer to figure 1 and figure 2 , the temperature uniform microchannel heat sink of the present invention comprises: a substrate 1, a cooling liquid distributor 4, a cooling liquid confluence 2, a cooling liquid confluence 6, The partition 3 and the partition 5, wherein the coolant distributor 4 is located in the middle, the coolant confluence 2 and the coolant confluence 6 are located on both sides, and the partition 3 is located between the coolant distributor 4 and the coolant confluence 2, The partition 5 is located between the coolant distributor 4 and the coolant collector 6 .

[0032] The structures of the base plate, the coolant distributor, and the coolant confluence are described in detail below.

[0033] 1. Substrate

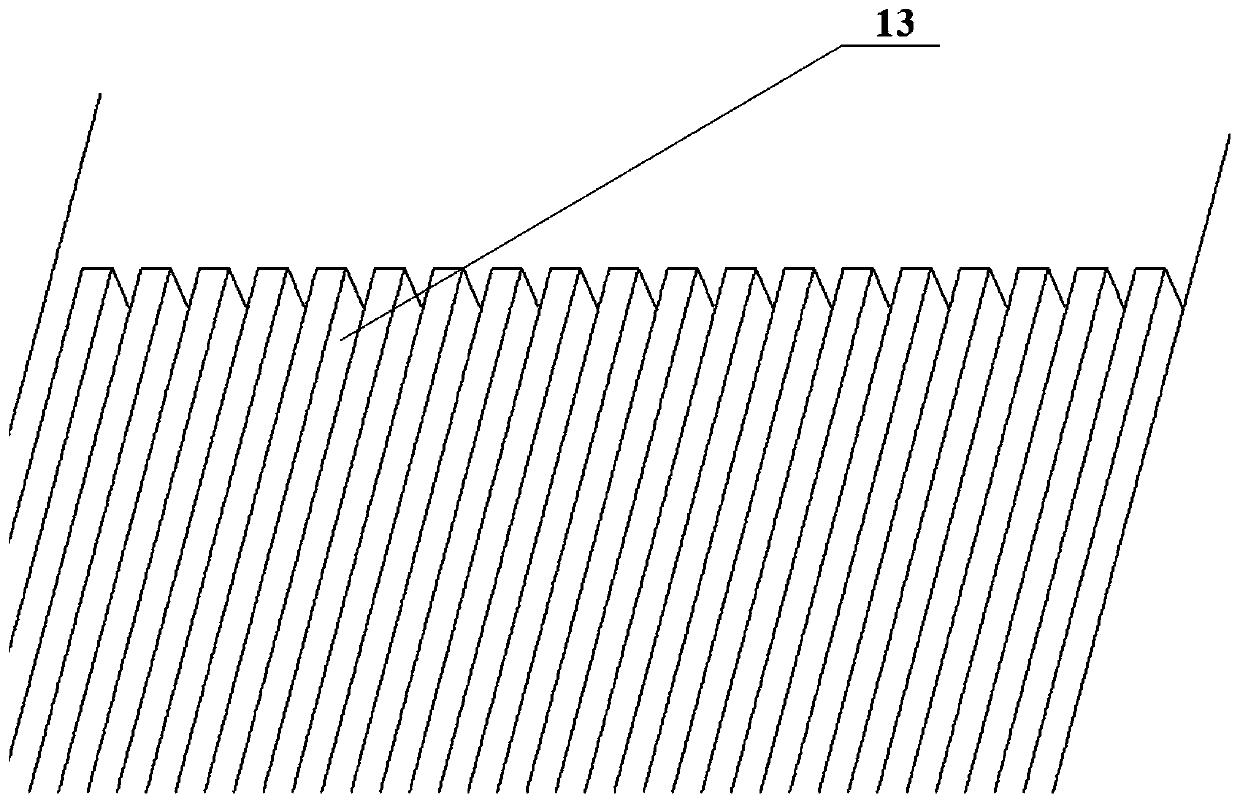

[0034] refer to figure 1 , figure 2 and image 3 , there are 2 on the top of the substrate 1 k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com