A kind of preparation method of zinc oxide graphene field effect tube

A technology of field effect transistors and graphene, which is applied in the direction of transistors, semiconductor/solid-state device manufacturing, semiconductor devices, etc., can solve problems such as many influencing factors, cumbersome preparation process, and damage to the integrity of another material, and achieve conductivity changes. Effects of acceleration, sensitivity enhancement, and Fermi level improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) prepare graphene film with chemical vapor phase method on substrate:

[0038] Put the base copper sheet into the furnace, feed hydrogen and argon or nitrogen to protect and heat to 1000°C, stabilize the temperature, and keep it for 20 minutes; then stop feeding the protective gas, and change to methane gas for 30 minutes, and the reaction is complete; cut off the power and turn off Methane gas, and then pass through the protective gas to exhaust the methane gas. Under the environment of the protective gas until the tube is cooled to room temperature, the metal foil is taken out to obtain graphene on the metal foil.

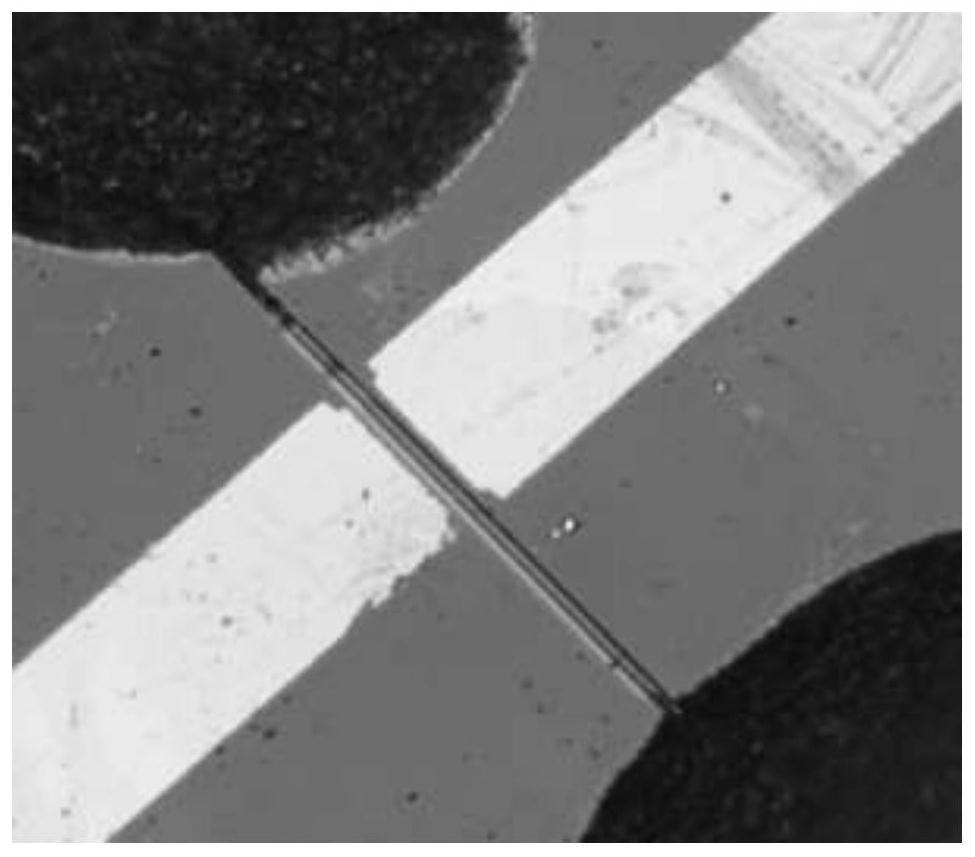

[0039] (2) Prepare a graphene-based field effect transistor on a graphene film:

[0040] (a) Photolithography: use positive photoresist as the photoresist, 5-inch chrome plate as the mask plate, the designed channel length is 30 microns; the developer corresponds to the photoresist, and the development time is 30s; pre-baking and post-baking The drying...

Embodiment 2

[0051] Design 8 groups of parallel experiments, design step (4) When the drying temperature of the liquid silver paste at the fixed end of the zinc oxide microrod is 55, 60, 75, 90, 105, 120, 135, 140°C, keep the drying time for 30min, The remaining materials and construction steps are the same as in Example 1, and the fixation effect of the obtained zinc oxide microrods is shown in Table 4.

[0052] Table 4 Effect of drying temperature of liquid silver paste on the fixation effect of zinc oxide microrods

[0053]

[0054] The experimental results show that the use of silver paste, which is liquid at normal temperature, becomes solid silver after heating, and when the heating temperature is 60-135 ° C, it can play a fixed role and achieve a suitable resistance value; especially, when drying and heating When the temperature reaches 105-135°C, the fixation is the most firm and the resistance value of silver is the smallest; when the temperature is lower than 60°C or higher th...

Embodiment 3

[0056] Design 7 groups of parallel experiments, design step (4) keep the liquid silver paste at the fixed end of zinc oxide microrods at 135°C for 8, 10, 15, 20, 25, 30, 32 minutes, and the rest of the materials and construction steps are the same as the examples 1, the fixation effect of the obtained zinc oxide microrods is shown in Table 5.

[0057] Table 5 The influence of liquid silver paste drying time on the fixation effect of zinc oxide microrods

[0058]

[0059] The experimental results show that when the silver paste is used for fixing, when the drying heating time is 10-30 minutes, the silver can play a fixing role and reach a suitable resistance value; especially, when the drying heating time reaches 20-30 minutes, the fixing The most solid and the resistance value of silver is the smallest; when the time is lower than 10min or higher than 30min, the fixation effect is not good and the resistance value is too large, which cannot make electrons effectively transp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com