Device and method for improving high-definition zoom lens assembling and adjusting efficiency and imaging quality

A zoom lens and imaging quality technology, applied in the field of optics, can solve the problem of not being able to detect changes in image quality in a timely manner, and achieve the effects of improving installation and calibration efficiency and imaging quality, improving installation and calibration efficiency, and facilitating adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach ( 1

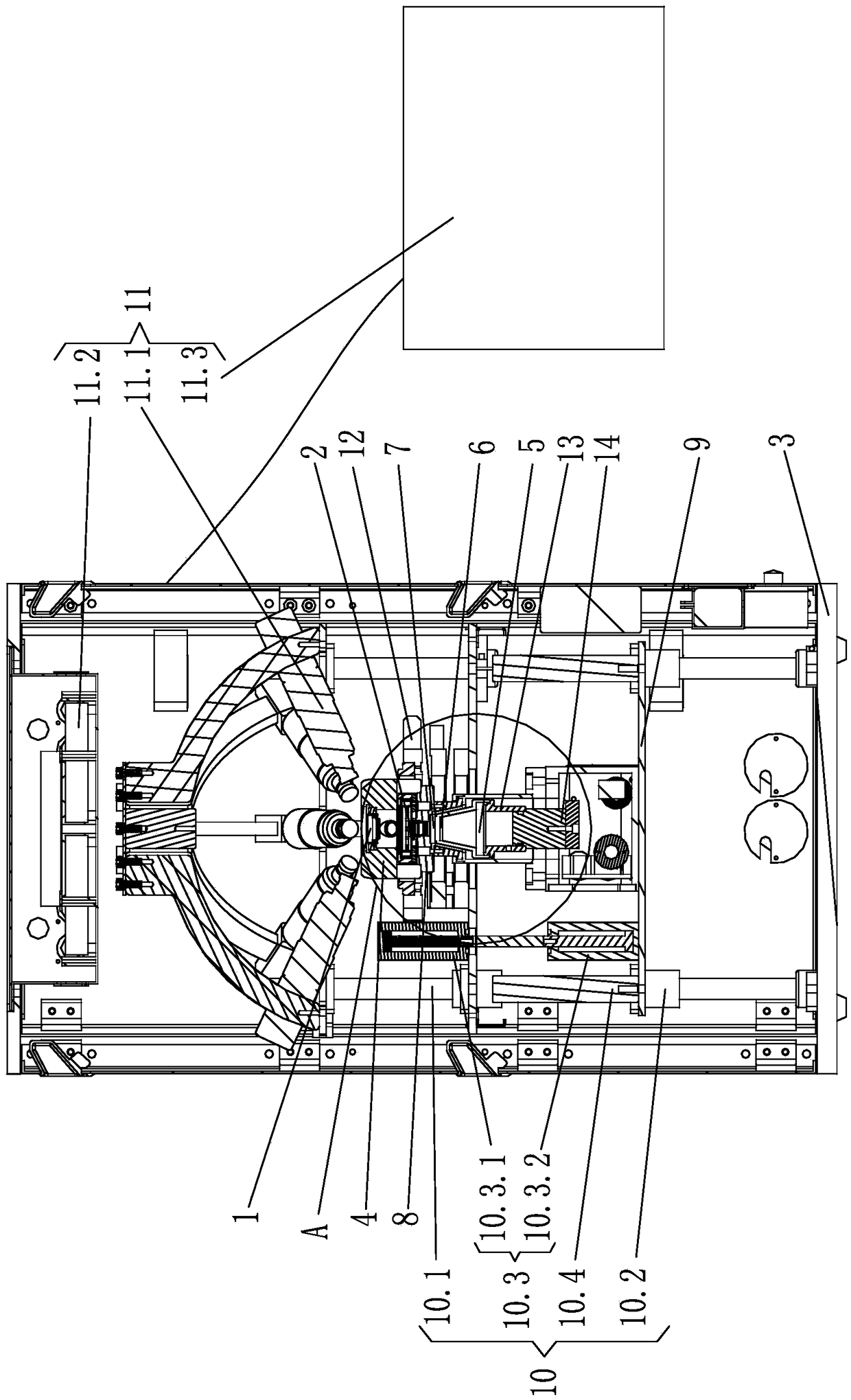

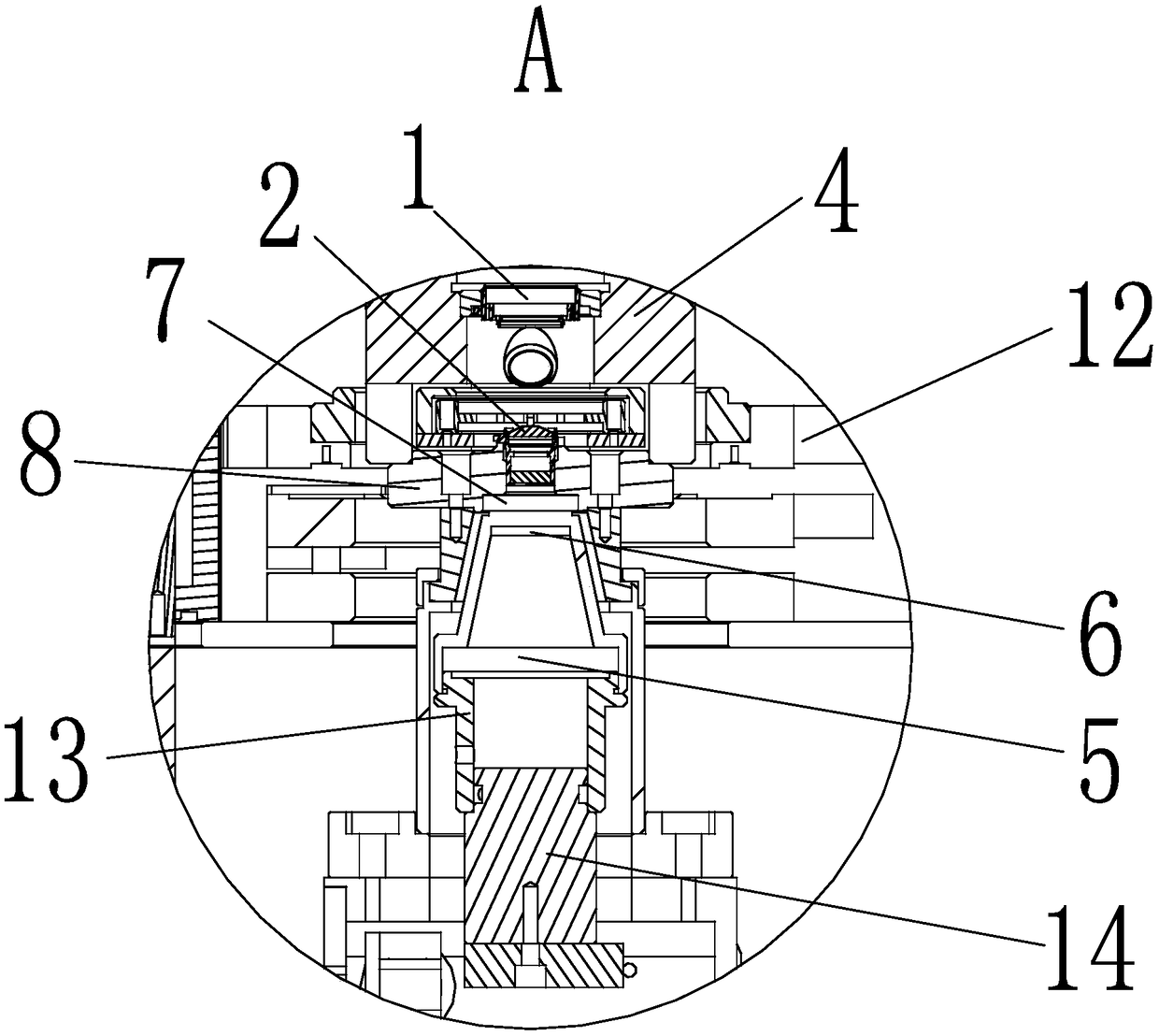

[0040] Such as figure 1 - Figure 7 Shown here is a device for improving the installation and calibration efficiency and imaging quality of a high-definition zoom lens provided by the present invention. The high-definition zoom lens includes a front lens group 1 and a rear lens group 2 coaxially arranged below the front lens group 1. The rear lens group 2 includes a rear lens barrel 2.1, a rear lens group 2.2 fixed at the lower end of the rear lens barrel 2.1, and a key element lens group 2.3 to be adjusted movably placed in the upper end of the rear lens barrel 2.1, and is characterized in that: The device includes a rack 3 and a front group placement seat 4 fixed on the rack 3 for placing the lens front group 1. The device also includes a front group placement seat 4 arranged in order from far to near along the optical axis. The light source 5, the homogenizing plate 6, the reticle 7 and the rear group placement seat 8 for placing the lens rear group 2, the light source 5, the...

specific Embodiment approach ( 2

[0049] A method for improving the installation and calibration efficiency and imaging quality of a high-definition zoom lens is characterized in that the method includes the following steps:

[0050] ① Install the front lens group 1 in the front group placement base 4, use the lifting drive mechanism 10 to drive the lifting platform 9 down to leave the detection position, then install the lens rear group 2 in the rear group placement base 8, and then use the lifting drive mechanism 10 Drive the lifting platform 9 up to the detection position;

[0051] ②Turn on the light source 5, and use the lifting adjustment assembly 14 to adjust the position of the reticle 7 relative to the rear lens group 2, so that the pattern on the reticle 7 passes through the rear lens group 2 and the front lens group 1 and then is in the multi-optical MTF tester 11. Form a clear image;

[0052] ③According to the real-time detection results of the imaging quality of the HD zoom lens by the multi-optical MTF ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com