Large-aperture high-power laser frequency doubling crystal edge self-locking clamping device and method

A frequency doubling crystal and self-locking clip technology, applied in the field of large-diameter high-power laser frequency doubling crystal edge self-locking clamping devices, can solve the problems of uneven internal stress distribution, low assembly efficiency, and reduced damage threshold, and achieve simplification. Clamping device and process, the effect of improving the efficiency of installation and calibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

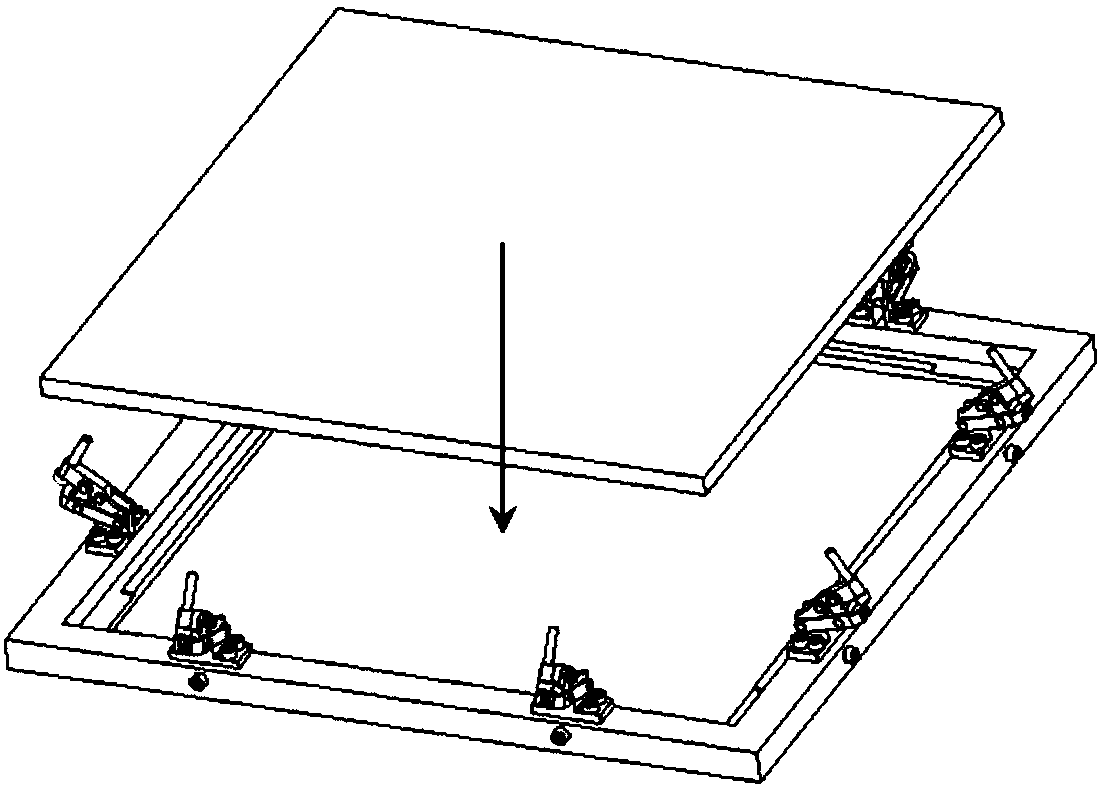

[0031] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

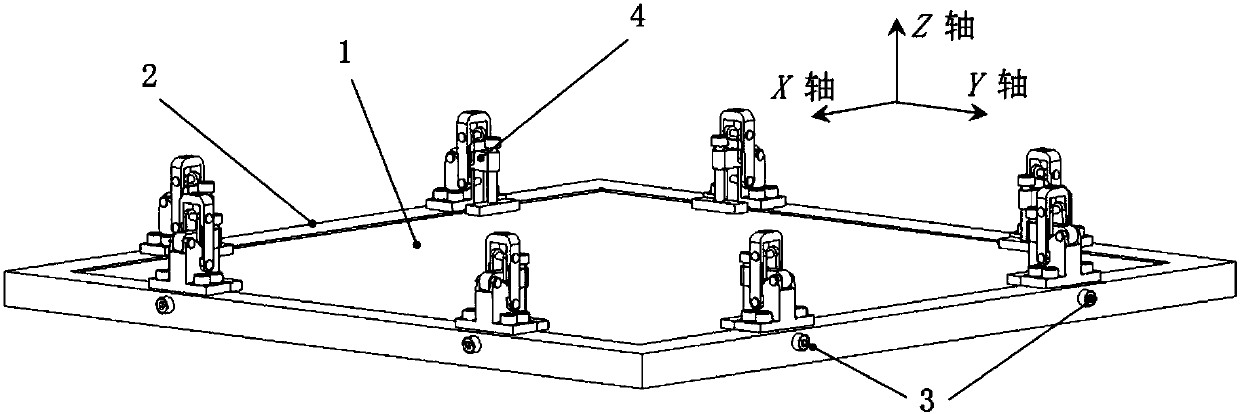

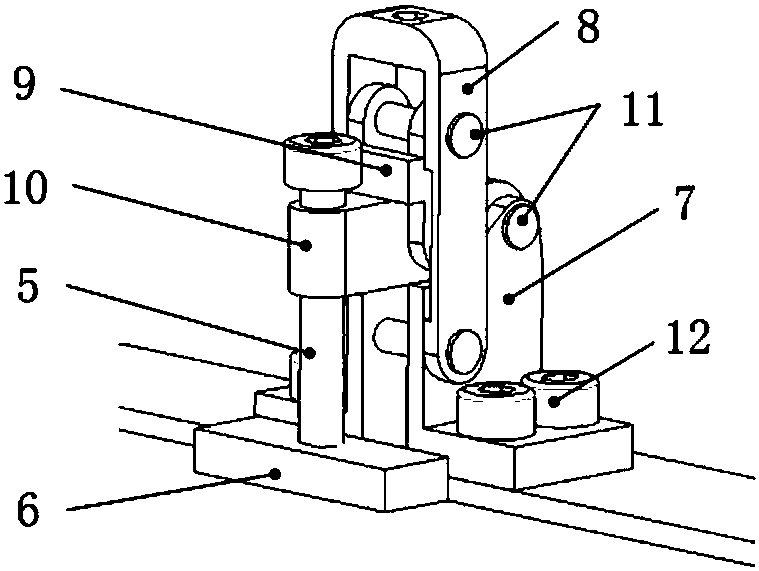

[0032] Such as figure 1 and 2 As shown, the present invention is a large-caliber high-power laser frequency-doubling crystal edge self-locking clamping device, which mainly consists of a laser frequency-doubling crystal 1, an outer support frame 2, a lateral limit screw 3, and an edge self-locking clamp 4. The pre-tightening screw 5 and the spacer 6 are composed.

[0033] The outer support frame 2 is a back-shaped frame body, and the inner bottom surface is provided with four precisely polished support bosses (flatness ±0.005mm), which are used to realize accurate positioning and precise positioning of the back (Z direction) of the laser frequency doubling crystal 1. Support; there are two M4 refined fine thread through holes on each adjacent side for installing the lateral limit screw 3; each of the four sides of the top surface has eight M4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com