A kind of optical axis angle adjustment method

A technology of optical axis and angle, which is applied in determining the optical axis, testing optical performance, determining the position of the lens, etc., can solve the problems of high stress and poor precision, and achieve the goal of improving stability, improving efficiency of installation and calibration, and improving adjustment accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

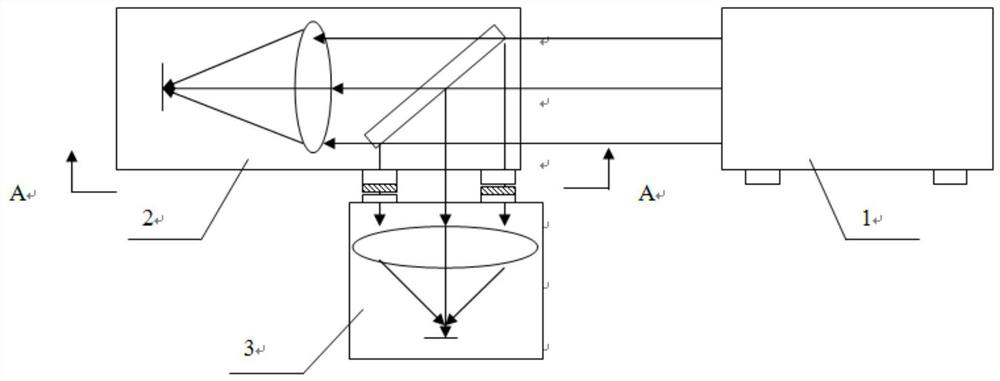

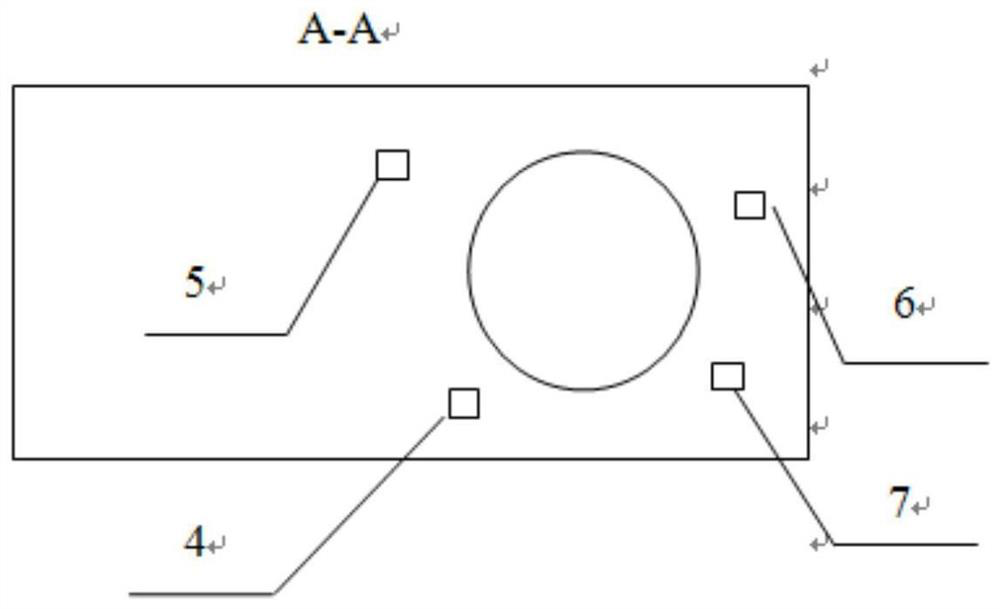

Method used

Image

Examples

Embodiment 1

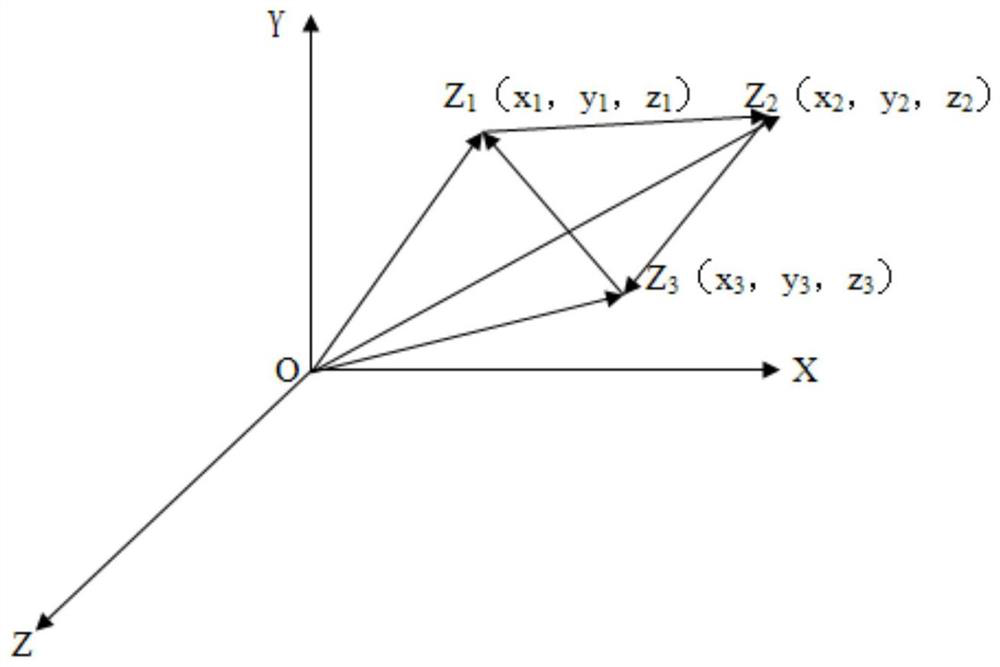

[0036] The azimuth deviation of the laser receiving optical axis is -1', the pitch deviation is -1.5', and the coordinates of the three spacers are as follows Figure 4 As shown, they are O(0, 0, 0), z1 (-42.5, 162.5, z1), z2 (219, 145, z2), z3 (219, 3.5, z3), and substitute into equations (1), ( 2), (3), can be solved

[0037] z1=0.029mm

[0038] z2 = 0.063mm

[0039] z3 = 0.032mm

Embodiment 2

[0041] The azimuth deviation of the laser receiving optical axis is -30", the pitch deviation is -1.5', and the coordinates of the 6 spacers are as follows Figure 5 As shown, they are O(0, 0, 0), z1 (0, 307.5, z1), z2 (230.4, 307.5, z2), z3 (0, 128.2, z3), z4 (230.4, 128.2, z4), Substituting z5(230.4, 0, z5) into equations (1), (2), (3), the solution is

[0042] z1=0.067mm

[0043] z2 = 0.084mm

[0044] z3 = 0.030mm

[0045] z4=0.045mm

[0046] z5 = 0.017 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com