Volumetric heat exchanger with self-excited pulsating enhanced heat exchange function and working method thereof

An enhanced heat transfer, volumetric technology, applied in the direction of heat exchanger type, indirect heat exchanger, heat transfer modification, etc., can solve the problem of not being able to use beneficial structural vibration, not being able to grasp the relationship between pulsating flow and pipeline structure vibration, etc. problem, to achieve the effect of reducing heat transfer area and material consumption, compact structure and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the above objects, features and advantages of the present invention more obvious and understandable, specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0039] Those skilled in the art can understand that unless otherwise defined, all terms (including technical terms and directional terms) used herein have the same meanings as commonly understood by those of ordinary skill in the art to which the present invention belongs.

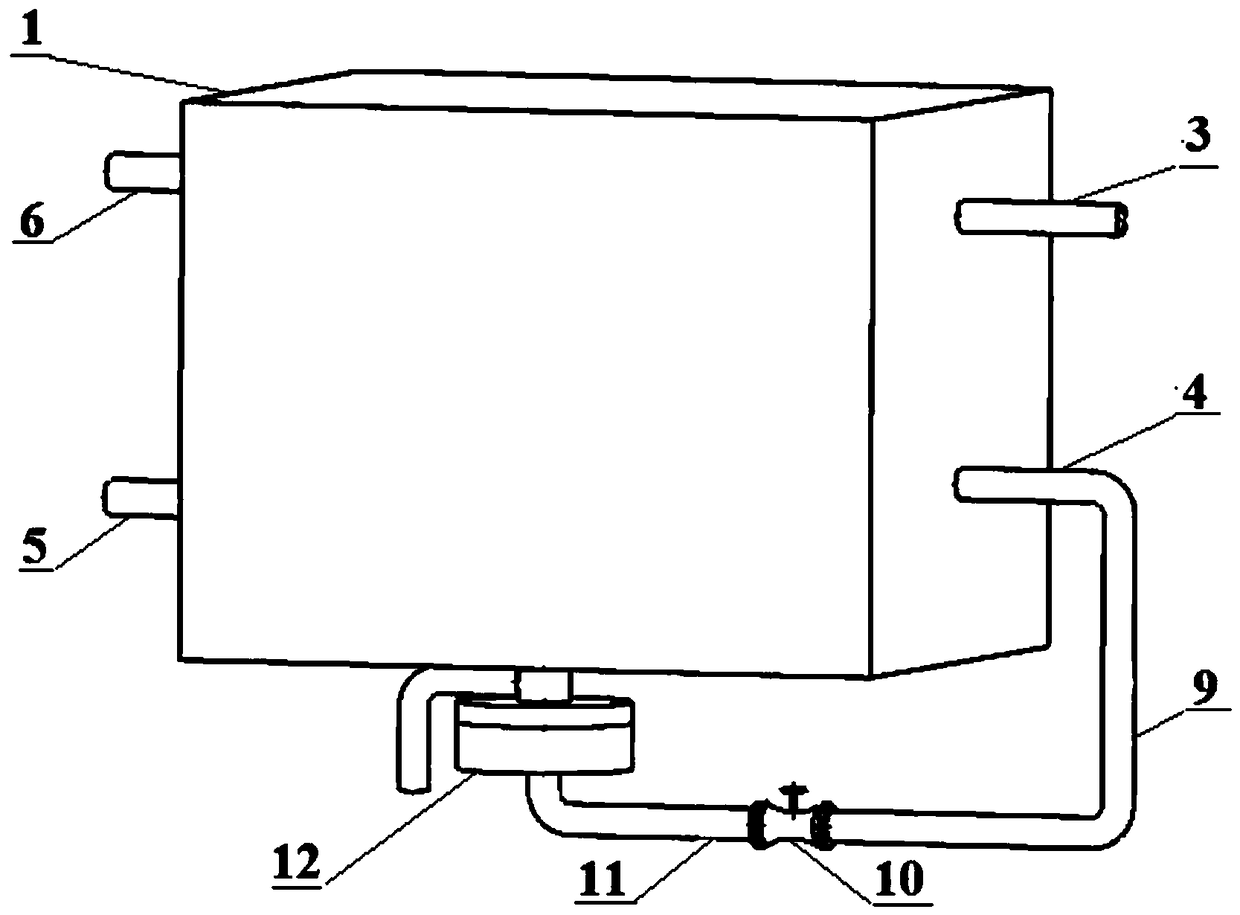

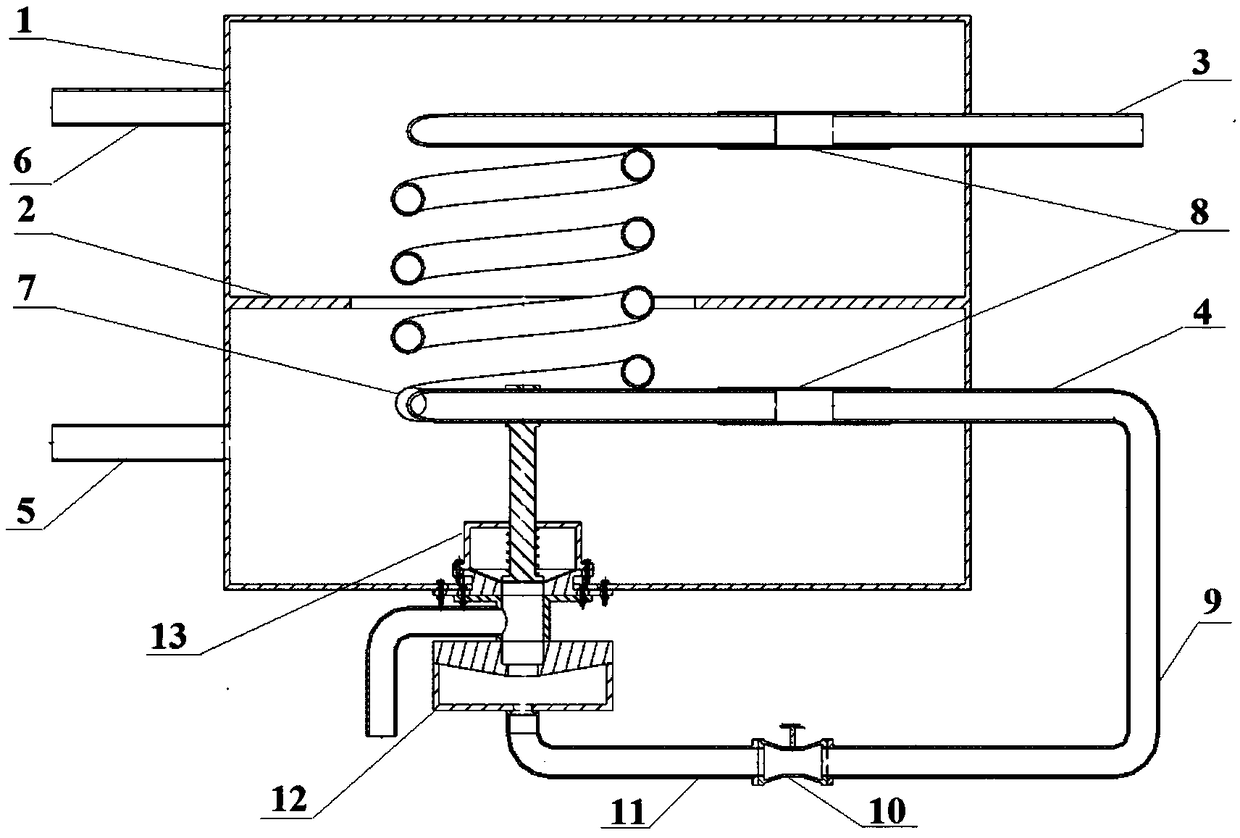

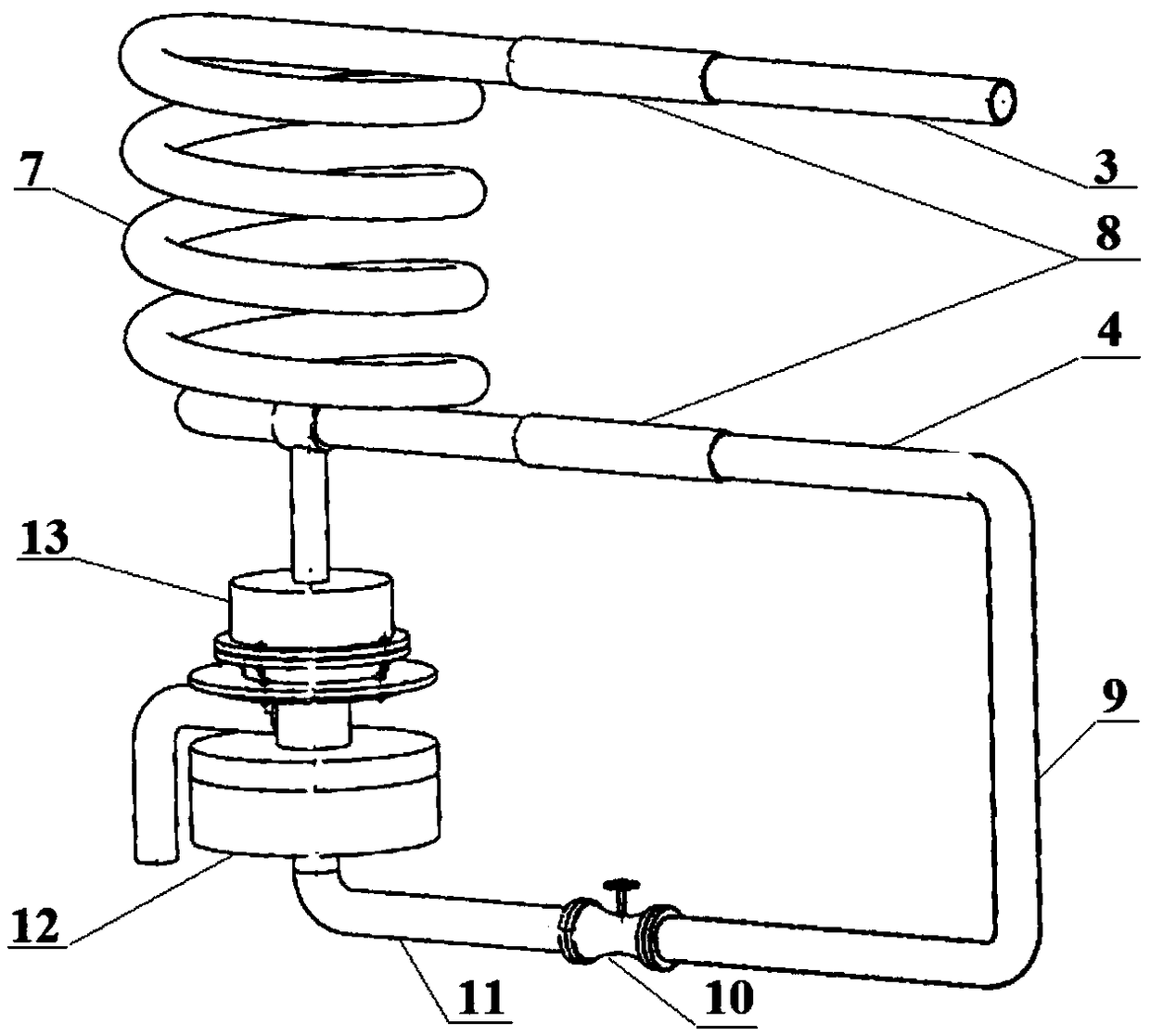

[0040] Such as Figure 1 to Figure 4 As shown, it is a self-excited pulsation-enhanced volumetric heat exchanger of the present invention, which includes a shell 1, a partition plate 2, a heat medium inlet pipe section 3, a heat medium outlet pipe section 4, a refrigerant inlet pipe section 5, and a refrigerant outlet pipe section Pipe section 6, heat exchange tube 7, hose 8, flow limiting valve 10, self-excited oscillation device 12 and pulsating hydraulic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Pitch | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com