Post-tensioning method up-lift pile used in combination with pile body post-grouting and construction method of up-lift pile

A construction method and technology of uplift piles, which are applied in basic structure engineering, sheet pile walls, buildings, etc., can solve problems such as increasing project cost, and achieve the effect of reducing project cost, facilitating implementation, and maintaining a central position.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

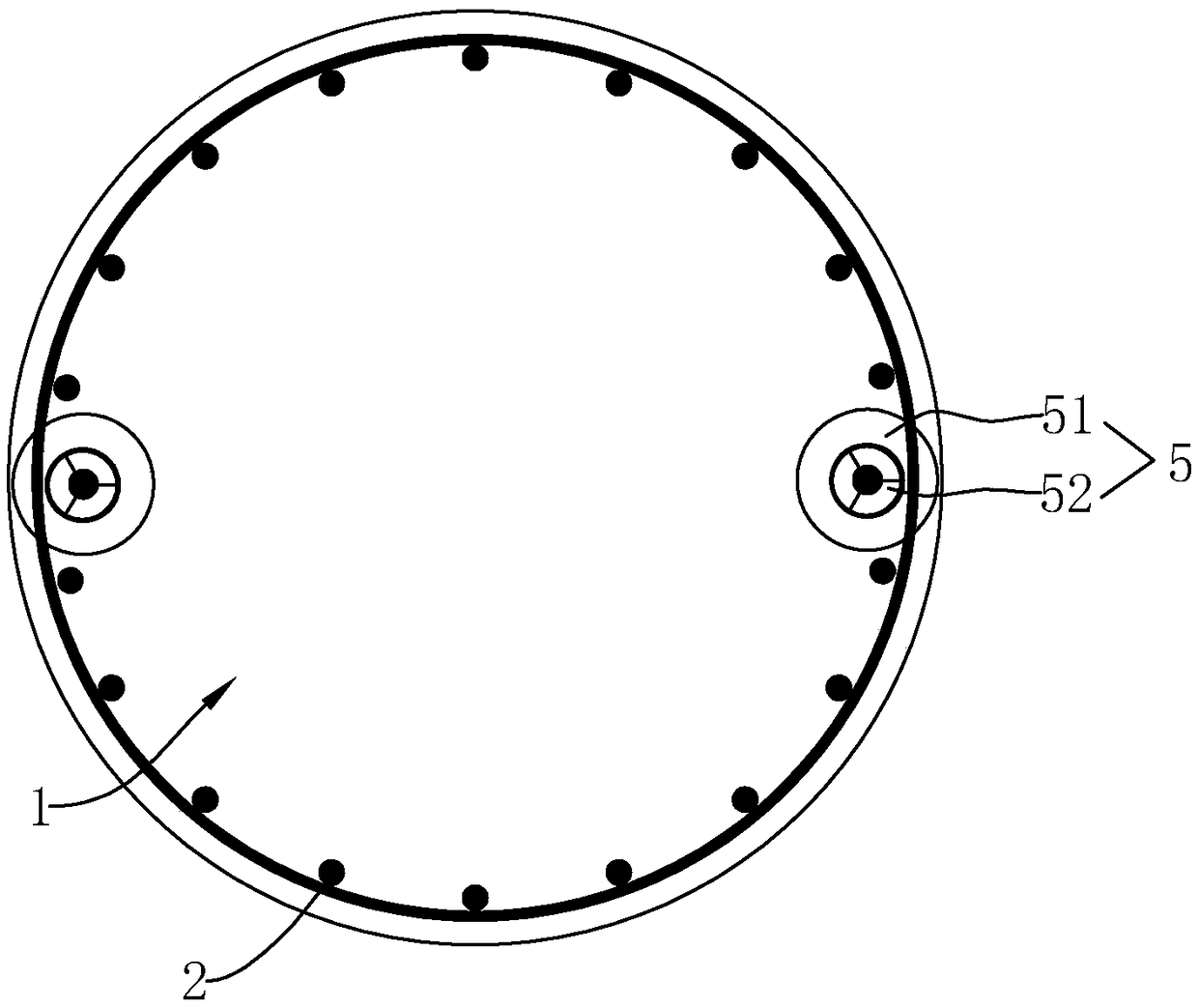

Image

Examples

Embodiment 2

[0061] A construction method of a post-tensioned uplift pile combined with grouting behind the pile, including the following construction steps:

[0062] Step 1: Make the main body 1 of the uplift pile, pre-embed the grouting pipe 3, and complete the grouting of the pile body in the grouting pipe 3;

[0063] Step 2: Sleeve the slurry isolation plug 41 on the prestressed tendon 4;

[0064] Step 3: implanting prestressed tendons 4 along the grouting pipe 3;

[0065] Step 4: chisel the pile head to the design pile top elevation, apply prestress to the prestressed tendon 4 and lock it to the design locking tension value;

[0066] Step 5: Perform waterproof treatment on the pile head of the main body 1 of the uplift pile.

[0067] Such as Figure 5 As shown, in step 1, the main body of the uplift pile 1 is pre-embedded with the grouting pipe 3 during processing, and grouting is injected into the grouting pipe 3 .

[0068] Such as Image 6 As shown, in step 2, the slurry isolat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com