Transversely-moving automatic entrance and exit type solid garage

A three-dimensional garage and traverse technology, applied in the fields of civil engineering, mechanical transmission and automatic control, and steel structure, can solve the problems of unfavorable promotion and popularization of mechanical three-dimensional garage, scratching vehicles, polluting people, etc. The effect of fire hazard, quick entry and exit, and convenient access to vehicles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

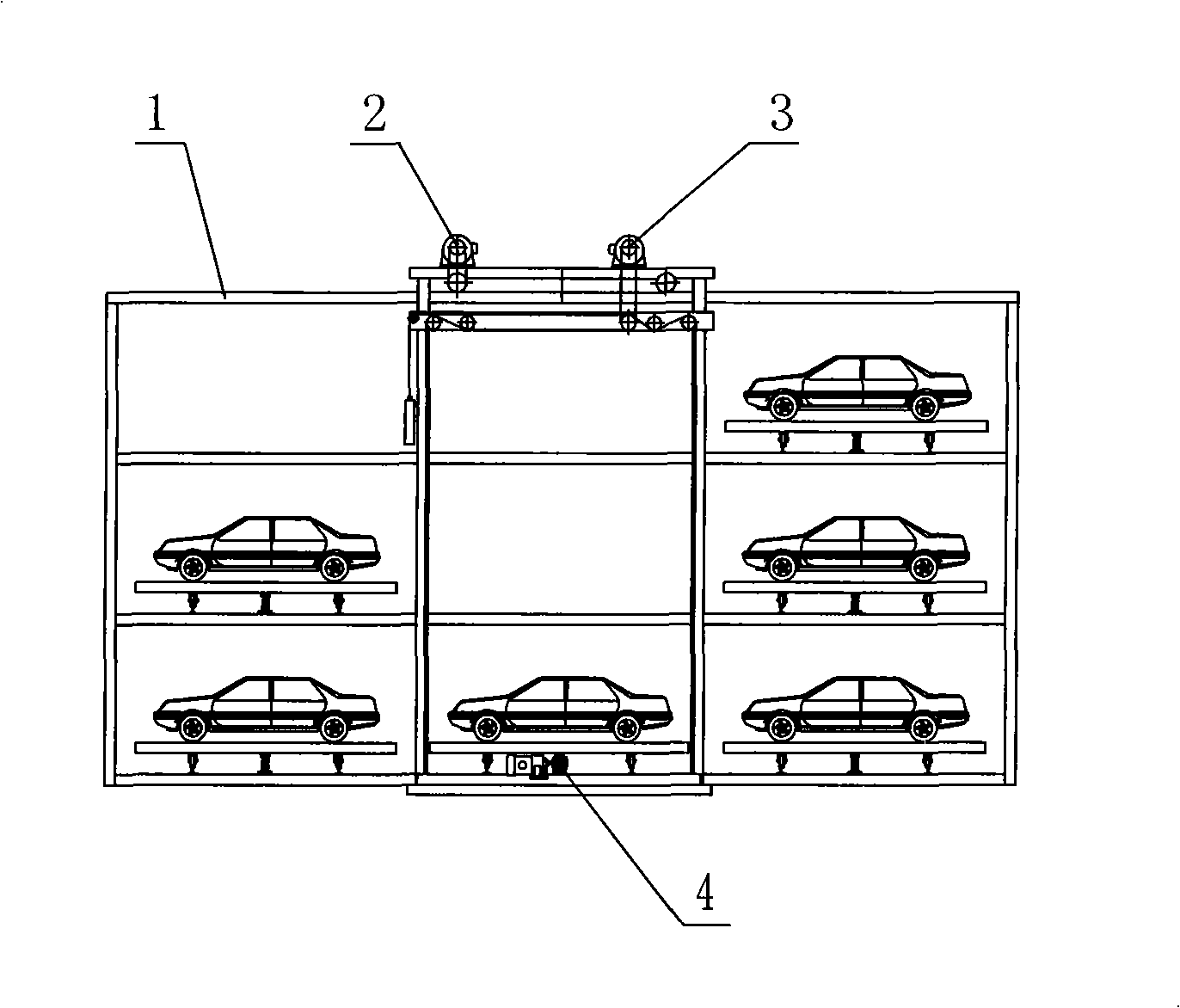

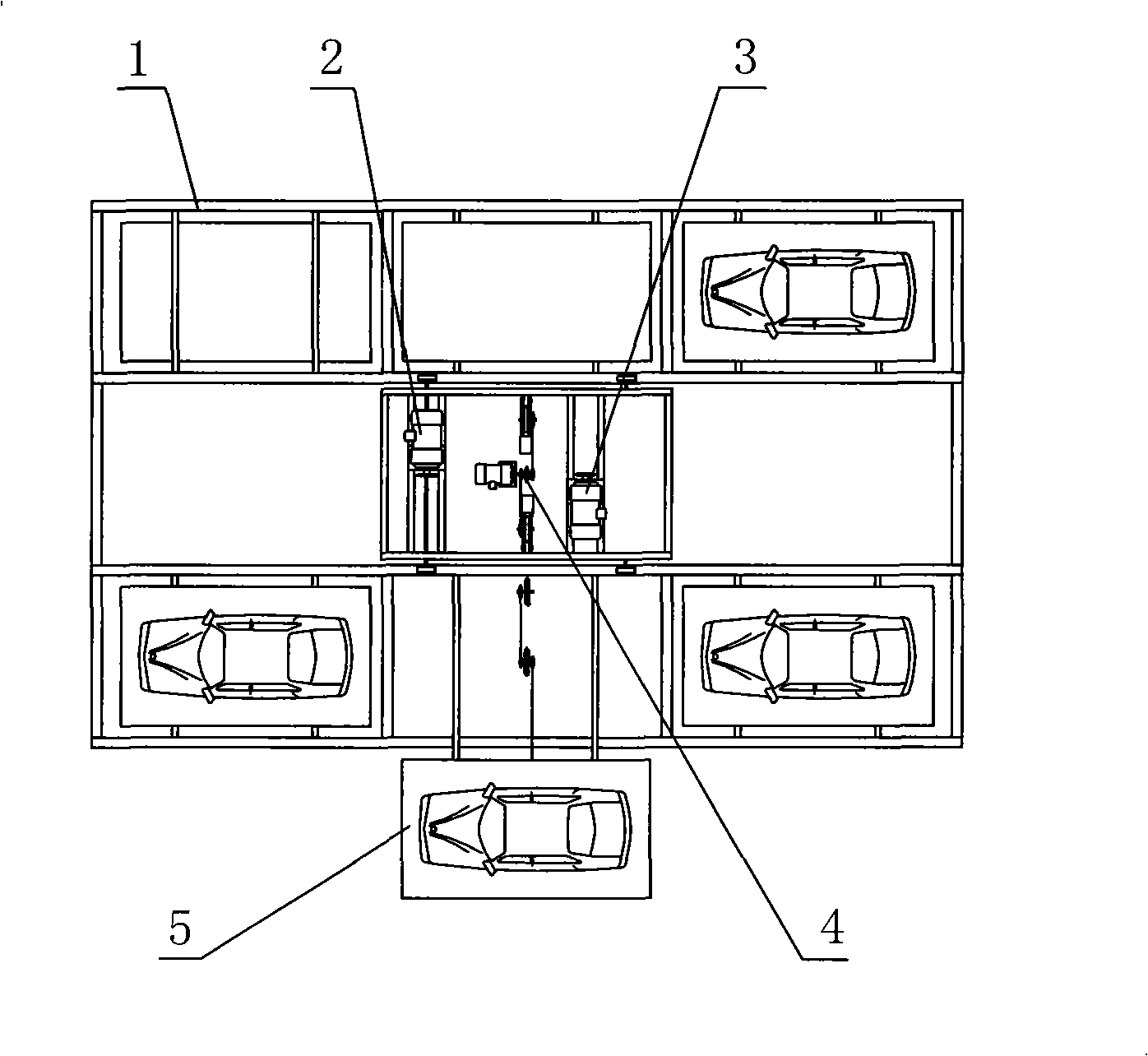

[0039] exist figure 1 , figure 2 When storing a car, the vehicle is parked on the vehicle-carrying pallet of the parking space 5 outside the door of the garage body 1. After the control system is started, the pallet-carrying mechanism 4 of the transport robot takes the car into the three-dimensional garage, and then the longitudinal mechanism 2. The lifting mechanism 3 is in operation, and the handling robot is about to send the pallet-loaded vehicle into the storage berth 4. When picking up the car, the longitudinal, lifting and lateral movement mechanisms operate in reverse order, and the pallet-loaded car is sent out to the parking space outside the garage.

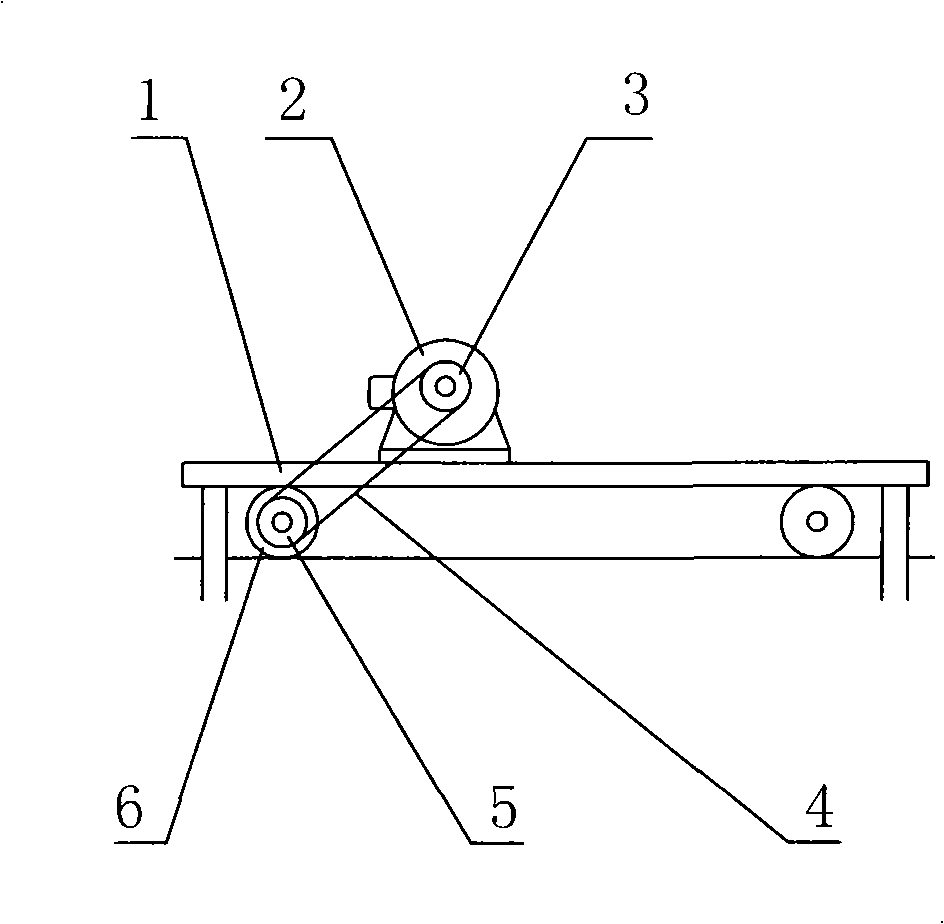

[0040] exist image 3 , Figure 4 Among them, when the longitudinal motor 2 rotates, the sprocket 3, the closed chain 4, and the sprocket 5 drive the lower guide wheel 6 of the crane frame 1 to rotate, so that the transfer robot can move longitudinally in the garage body operating space.

[0041] exist Figure 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com