Al-Zn-Mg series aluminum alloy profile material and preparing method thereof

An aluminum alloy profile and aluminum alloy technology, applied in the field of aluminum alloy processing, can solve the problems of high price of scandium, unable to meet the strength requirements, poor corrosion resistance, etc., and achieve the effect of good spalling corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

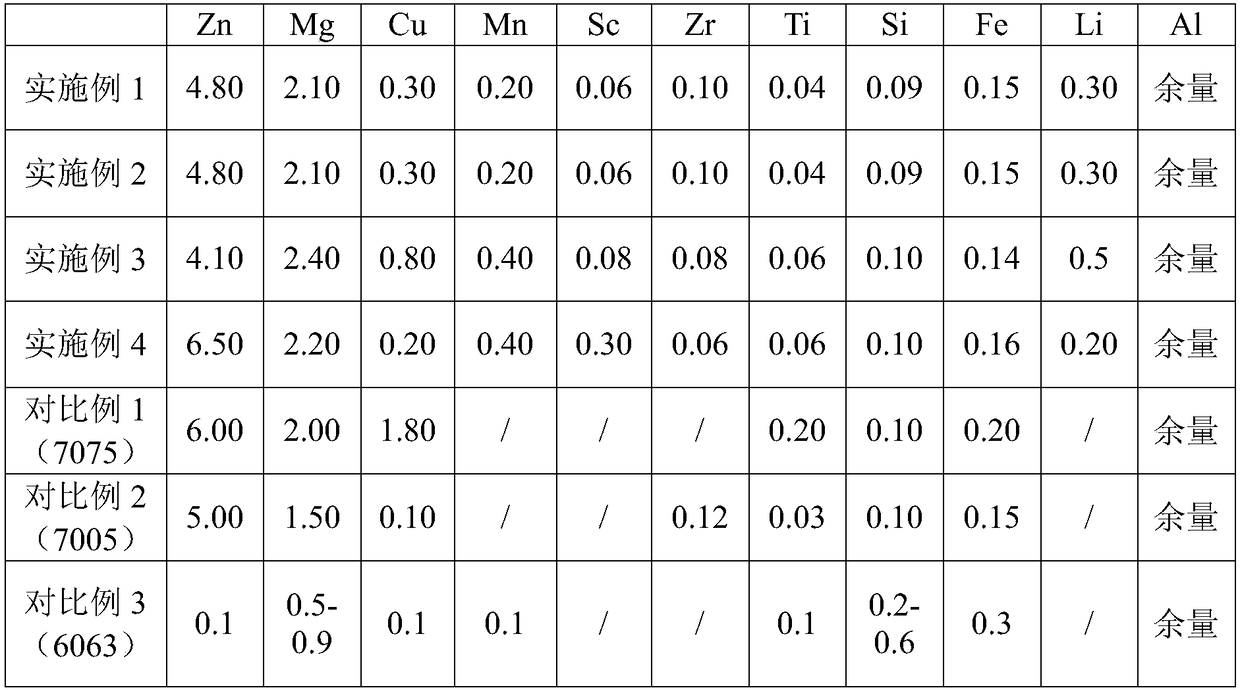

[0039] (1) Prepare materials according to 4.8wt% Zn, 2.1wt% Mg, 0.3wt% Li, 0.06wt% Sc, 0.1wt% Zr, 0.3wt% Cu, 0.2wt% Mn, 0.04wt% Ti, remaining Al , where Li, Cu, Mn, Zr, Sc, Ti, B are added in the form of master alloys.

[0040] (2) Melting in an electric furnace, adding aluminum ingots first, after melting, adding Al-Cu, Al-Mn, Al-Zr, Al-Sc, Zn, Mg, Al-Li, the melting temperature is controlled at 740-760 degrees, electromagnetic Stir for 10 minutes, pass in chlorine-argon mixed gas to degas, let it stand for 15-20 minutes, remove slag, add Al-Ti-B wire online, filter through ceramic filter, semi-continuous ingot casting, control the pouring temperature at 720-740 Spend.

[0041] (3) Put the cast ingot of step (2) into an annealing furnace for homogenization annealing, the process condition is 460-480 degrees, heat preservation for 12 hours, and cool out of the furnace.

[0042] (4) Put the cast ingot of step (3) into a heating furnace, heat it to 520 degrees, and after 4 hou...

Embodiment 2

[0046] The preparation method of this example is the same as that of Example 1, the difference is that before aging, the extruded profiles are not quenched by online air, but are placed in a quenching furnace, heated to 460-480 degrees, kept for 1-2 hours, and then water-cooled Quenching, and then aging, the aging process is the same as in Example 1.

Embodiment 3

[0048] According to 4.1wt% Zn, 2.40wt% Mg, 0.5wt% Li, 0.08wt% Sc, 0.08wt% Zr, 0.8wt% Cu, 0.4wt% Mn, 0.06wt% Ti, surplus Al, prepare materials, the specific operation steps are the same In Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com