Persimmon vinegar and preparation method thereof

A technology of persimmon vinegar and persimmon, which is applied in the preparation of vinegar, biochemical equipment and methods, methods based on microorganisms, etc., can solve the problems of acid production ability, alcohol resistance ability and aroma production ability, etc. effect, mild sourness, shortening of fermentation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A kind of persimmon vinegar provided in this embodiment, said persimmon vinegar is mainly prepared from the following raw materials according to the following weight: 100-150g of persimmon; 200-300mL of water. In the present embodiment, the persimmon vinegar is mainly prepared from the following raw materials according to the following weight: 100 g of persimmons; 200 mL of water.

[0030] This embodiment also discloses a kind of preparation method of persimmon vinegar, it is characterized in that, concrete steps are as follows:

[0031] S1, collect the persimmons and clean them, then cut into pieces and set aside;

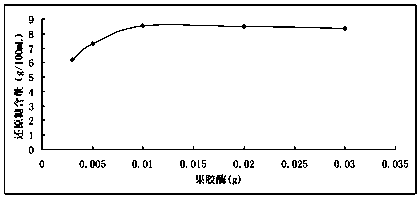

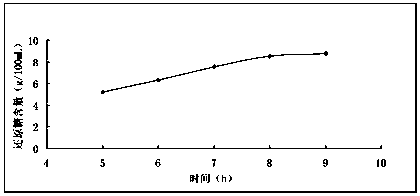

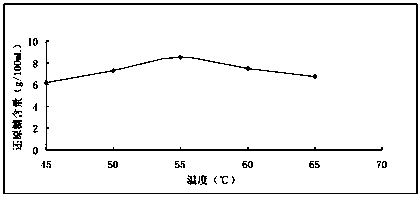

[0032] S2. In step S1, add 0.01%-0.03% of the persimmon content of pectinase and mix it. After heating to 60°C, add the saccharification solution to carry out the saccharification reaction for 8 hours; measure the reducing sugar content of the saccharification solution through the experiment on the influencing factors of saccharification, To determine the ...

Embodiment 2

[0039] A kind of persimmon vinegar provided in this embodiment, said persimmon vinegar is mainly prepared from the following raw materials according to the following weight: 120g of persimmons; 220mL of water.

[0040] This embodiment also discloses a kind of preparation method of persimmon vinegar, it is characterized in that, concrete steps are as follows:

[0041] S1, collect the persimmons and clean them, then cut into pieces and set aside;

[0042] S2. In step S1, add 0.02% of the persimmon content of pectinase and mix it. After heating to 55°C, add the saccharification solution to carry out the saccharification reaction for 6 hours; measure the reducing sugar content of the saccharification solution through experiments on the influencing factors of saccharification to determine the optimum Optimum saccharification process conditions to obtain persimmon saccharification liquid;

[0043] S3. Mixed fermentation: add activated yeast and acetic acid bacteria to the persimmon...

Embodiment 3

[0048] The persimmon vinegar provided in this embodiment is mainly prepared from the following raw materials according to the following weight: 150 g of persimmons; 300 mL of water.

[0049] This embodiment also discloses a kind of preparation method of persimmon vinegar, it is characterized in that, concrete steps are as follows:

[0050] S1, collect the persimmons and clean them, then cut into pieces and set aside;

[0051] S2. In step S1, add 0.03% of the persimmon content of pectinase and mix. After heating to 58°C, add the saccharification solution to carry out the saccharification reaction for 8 hours; measure the reducing sugar content of the saccharification solution through experiments on the influencing factors of saccharification to determine the optimum Optimum saccharification process conditions to obtain persimmon saccharification liquid;

[0052] S3. Mixed fermentation: add activated yeast and acetic acid bacteria to the persimmon saccharification liquid prepar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com