Corrosion-inhibiting bactericide for shale gas field

A bactericide and corrosion inhibition technology, applied in biocides, applications, disinfectants, etc., can solve problems such as electrochemical corrosion and bacterial corrosion, and achieve low dosage, good corrosion inhibition effect, and good bactericidal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

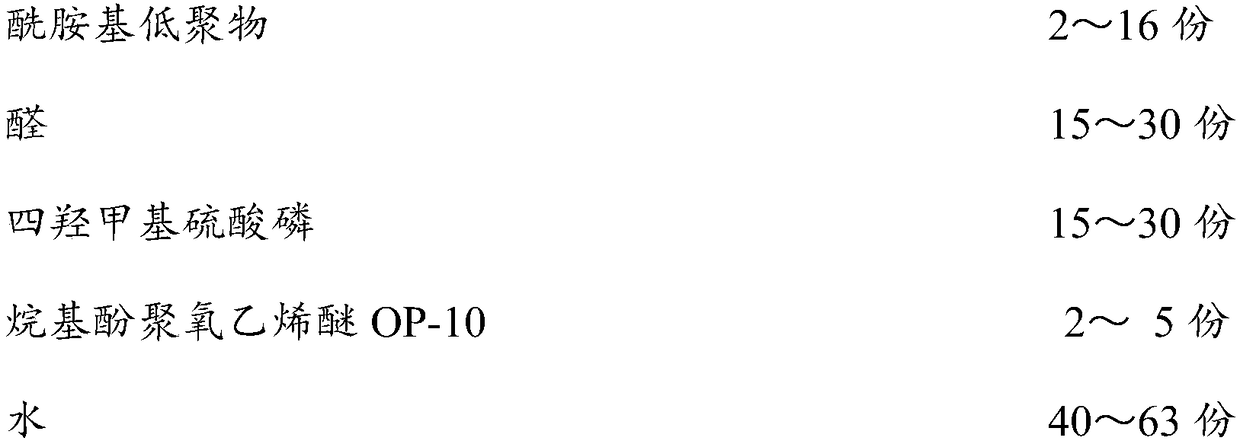

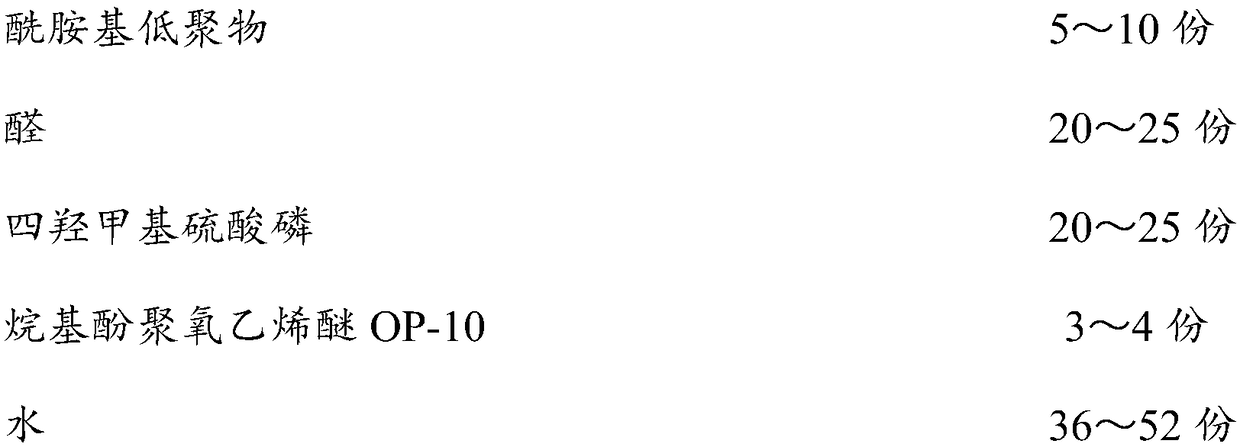

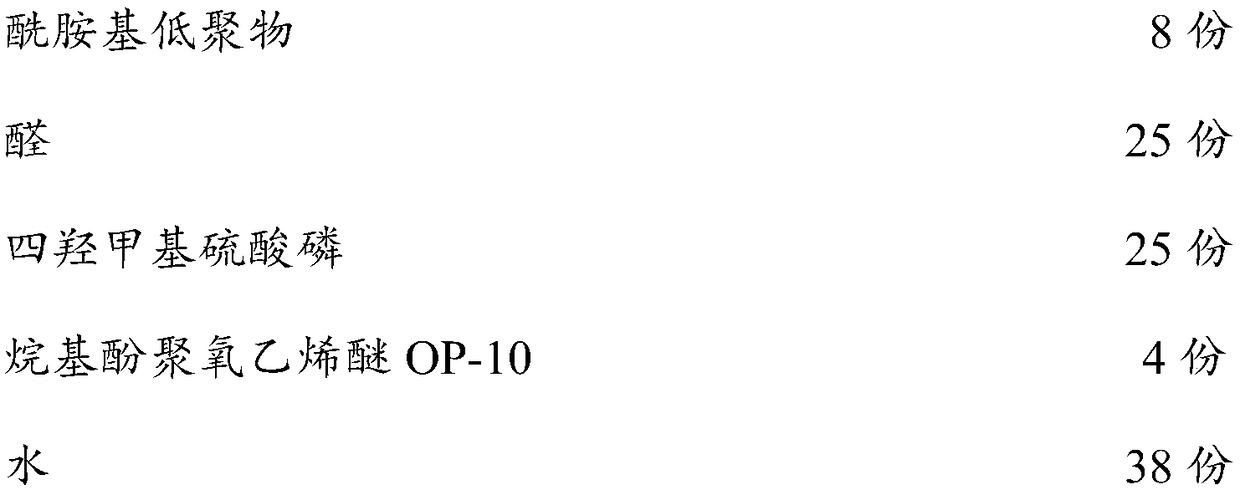

[0021] In parts by weight, the shale gas field corrosion inhibitor bactericide of the present embodiment comprises:

[0022]

[0023] Wherein, the alkyl allyl quaternary ammonium salt in the amido oligomer is dodecyl dimethyl allyl ammonium chloride, the molecular weight of the amido oligomer is 1210, and the aldehyde is glutaraldehyde.

experiment example 1

[0025] Produced water samples from a shale gas field in Sichuan, prepared the corresponding culture medium according to "Standards for Bacterial Analysis of Oil and Gas Field Injection Water by Extinction Dilution Method" SY / T 0532-2012, and counted and measured the sulfate reduction in the water sample by using the extinction dilution method Bacteria is 4.5×10 3 Individual / mL, saprophytic bacteria: 1.5×10 3 Individual / mL, iron bacteria is 1.1×10 3 cells / mL, the total number of bacteria is 7.1×10 3 individual / mL.

[0026] Using the corrosion-inhibiting bactericide of Example 1, respectively inject the bactericide into the water samples at room temperature, and sterilize for 4 hours. The sterilized water sample and the blank sample were injected into the test bottle, and left at room temperature for 7 days to test the number of bacteria in the water sample. The bacterial test results are shown in Table 1:

[0027] The bactericidal effect of table 1 different concentrations...

experiment example 2

[0031] Use the corrosion inhibitor bactericide of embodiment 1, concentration is 80mg / L, adopts 20# steel sample to carry out the corrosion test under normal temperature, and test water is the shale gas field produced water of experimental example 1, and the result is as shown in table 2:

[0032] The corrosion inhibition effect of corrosion inhibitor bactericide in the embodiment 1 of table 2

[0033]

[0034] Use the corrosion inhibitor bactericide of embodiment 1, concentration 80mg / L, test water is the shale gas field produced water of experimental example 1, and bactericidal effect is as shown in table 3:

[0035] The bactericidal effect of corrosion inhibitor bactericide in the embodiment 1 of table 3

[0036]

[0037]

[0038] The experimental results in Table 2 and Table 3 show that the corrosion inhibitor bactericide of the present invention has good corrosion inhibition and bactericidal effects on shale gas produced water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com