Consumable material with uniform color distribution for 3D printing pen

A 3D printing pen, cloth color technology, applied in the application, pencil lead, household utensils and other directions, can solve the problems of color paste/toner sedimentation, uneven color distribution, differences in physical and chemical properties, etc., to achieve small viscosity fluctuations and good increase. Sticky effect, good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

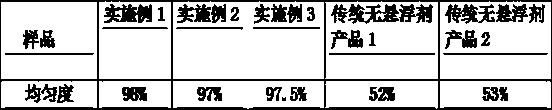

Examples

Embodiment 1

[0056] 1. Configure the raw materials of non-stick consumables for 3D printing pens according to the following ratio:

[0057] Polyurethane acrylic resin 80.23%

[0058] 2,4,6-Trimethylbenzoylphenylphosphonic acid ethyl ester 9.6%

[0059] 4-Dimethylaminobenzoic acid ethyl ester 2.5%

[0060] Cocoic Acid Methyl Monoethanolamide 2.5%

[0061] Ethylhexyl Palmitate 1.2%

[0062] Lithium magnesium silicate 1.5%

[0063] Light diffusing powder 1%

[0064] Color paste / toner balance

[0065] 2. Preparation method

[0066] Weigh polyurethane acrylic resin, ethyl 2,4,6-trimethylbenzoylphenyl phosphonate and ethyl 4-dimethylaminobenzoate respectively according to the proportion. The above materials are mixed and stirred evenly to prepare intermediate product A for use.

[0067] Weigh ethylhexyl palmitate, lithium magnesium silicate, methyl monoethanolamide cocoate and light diffusing powder respectively according to the proportioning ratio. Mix and stir the above materials even...

Embodiment 2

[0072] 2. Configure the raw materials of non-stick consumables for 3D printing pens according to the following ratio:

[0073] Polyurethane Acrylic 60%

[0074] 2,4,6-Trimethylbenzoylphenylphosphonic acid ethyl ester 12%

[0075] 4-Dimethylaminobenzoic acid ethyl ester 6%

[0076] Coco Methyl Monoethanolamide 6%

[0077] Ethylhexyl Palmitate 3%

[0078] Lithium magnesium silicate 3%

[0079] Light diffusing powder 2%

[0080] Color paste / toner balance

[0081] 2. Preparation method

[0082] Weigh polyurethane acrylic resin, ethyl 2,4,6-trimethylbenzoylphenyl phosphonate and ethyl 4-dimethylaminobenzoate respectively according to the proportion. The above materials are mixed and stirred evenly to prepare intermediate product A for use.

[0083] Weigh ethylhexyl palmitate, lithium magnesium silicate, methyl monoethanolamide cocoate, light diffusing powder, and color paste respectively according to the proportioning ratio. Heat together with the intermediate product A to...

Embodiment 3

[0086] 3. Configure the raw materials of non-stick consumables for 3D printing pens according to the following ratio:

[0087] Polyurethane Acrylic 88%

[0088] 2,4,6-Trimethylbenzoylphenylphosphonic acid ethyl ester 1%

[0089] 4-Dimethylaminobenzoic acid ethyl ester 1%

[0090] Cocoic Acid Methyl Monoethanolamide 1%

[0091] Ethylhexyl Palmitate 1%

[0092] Polyacrylamide 0.1%

[0093] Light diffusion powder 0.5%

[0094] Color paste / toner balance

[0095] 2. Preparation method

[0096] Weigh polyurethane acrylic resin, ethyl 2,4,6-trimethylbenzoylphenyl phosphonate and ethyl 4-dimethylaminobenzoate respectively according to the proportion. The above materials are mixed and stirred evenly to prepare intermediate product A for use.

[0097] Weigh ethylhexyl palmitate, polyacrylamide, methyl monoethanolamide cocoate, light diffusing powder, and color paste respectively according to the proportioning ratio. Heat together with the intermediate product A to 10-35°C, stir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com