Flame-retardant PVC masterbatch and preparation method thereof

A technology of color masterbatch and flame retardant resin, which is applied in the field of color masterbatch preparation, can solve the problems of low polymer temperature, different flame retardant properties of color masterbatch, uneven dispersion of flame retardants, etc., and achieve the distribution of flame retardant ability Uniform, uniform color distribution, high flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

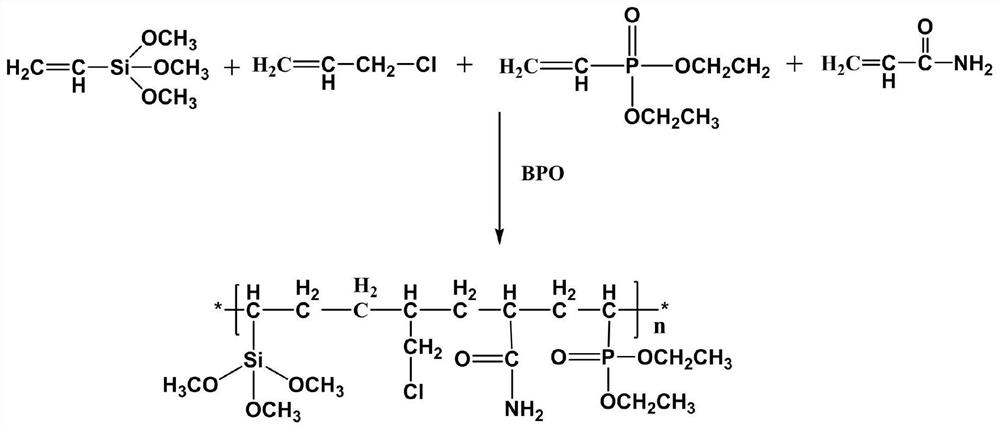

[0032]The specific preparation process of composite PVC flame retardant resin is as follows: add 1.48kg vinyltrimethoxysilane and 0.76kg allyl chloride to absolute ethanol, and add 1.64kg vinyl phosphate diethyl ester and 0.72kg After acrylamide was stirred and mixed evenly, 4.48kg of dibenzoyl peroxide was added to it, and then heated to 120°C for 5 hours to obtain a composite PVC flame-retardant resin;

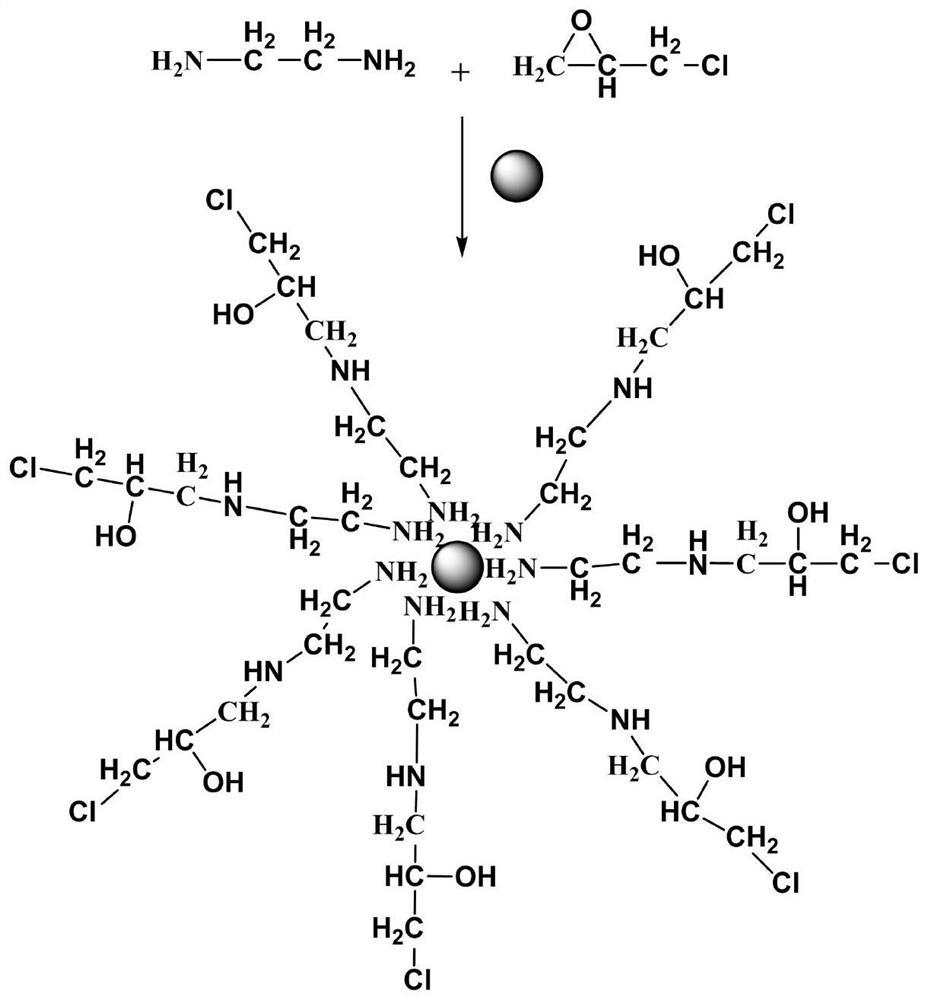

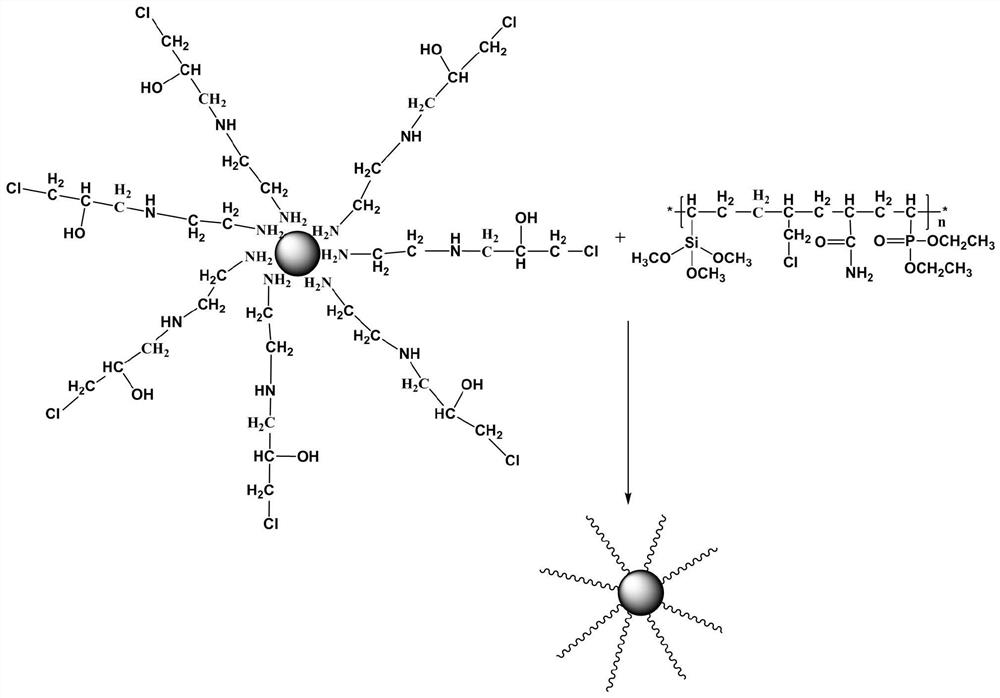

[0033] The specific preparation process of core-shell pigments and fillers is as follows:

[0034] Step 1, add 500g of inorganic pigment into 4L of water, mix and stir evenly;

[0035] Step 2, add 2.1L ethylenediamine and 0.55L sodium dodecylbenzenesulfonate to step 1, mix well and heat up to 60°C;

[0036] Step 3, keep the temperature constant, add 2.7L epichlorohydrin dropwise to step 2, stir while adding dropwise, after the dropwise addition is complete, keep the constant temperature reaction for 30-40min, then filter the obtained product, and then carry out the process ...

Embodiment 2

[0038] The specific preparation process of composite PVC flame retardant resin is as follows: add 1.48kg vinyltrimethoxysilane and 0.76kg allyl chloride to absolute ethanol, and add 1.64kg vinyl phosphate diethyl ester and 0.72kg After acrylamide was stirred and mixed evenly, 4.96kg of dibenzoyl peroxide was added to it, and then heated to 120°C for 5 hours to obtain a composite PVC flame-retardant resin;

[0039] The specific preparation process of core-shell pigments and fillers is as follows:

[0040] Step 1, add 500g of inorganic pigment into 4.5L of water, mix and stir evenly;

[0041] Step 2, add 2.35L ethylenediamine and 0.65L sodium dodecylbenzenesulfonate to step 1, mix well and heat up to 60°C;

[0042] Step 3, keep the temperature constant, add 2.8L epichlorohydrin drop by drop to step 2, stir while adding dropwise, after the dropwise addition is complete, keep the constant temperature reaction for 30-40min, then filter the obtained product, and then use ethanol to...

Embodiment 3

[0044] A preparation method of flame-retardant PVC color masterbatch, the specific preparation process is as follows:

[0045] In the first step, add 3.25kg of the composite PVC flame-retardant resin prepared in Example 1 and 0.85kg of the core-shell pigment and filler prepared in Example 1 into 5kg of ethanol, stir and mix evenly, heat up to 70°C, and then pour into the reaction vessel Add 0.45kg of diphenylmethane diisocyanate dropwise to the solution, stir vigorously while adding, the rate of addition is 8-10mL per minute, and react at constant temperature for 5 hours after the addition is complete;

[0046] In the second step, filter and wash the product obtained in the first step, then dry it at 50°C, put the obtained product into the open mill, melt it at 130°C for 4-6min, and then add it to the open mill 0.25kg of liquid paraffin and polyacrylamide mixture, add 0.15kg of methyl trifluoroacetate at the same time, smelt for 2-3min until the raw materials are mixed evenly,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com