UV-LED curing transfer printing ink and preparation method and application

A UV-LED and pad printing technology, which is applied in inks, applications, household appliances, etc., can solve problems such as poor adhesion of pad printing inks, and achieve good durability, good adhesion, and excellent boiling water resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0057] Another embodiment of the present invention also provides a method for preparing the UV-LED curing pad printing ink as described above, comprising the following steps:

[0058] Add acrylic acid prepolymer, monomer and dispersant to the mixer, stir at 600 rpm for 10 minutes, and stir evenly to obtain a mixture;

[0059] Put the adhesion promoter, photoinitiator, pigment, and surface additive into the mixture, disperse for 30 minutes at a speed of 1000 rpm, and stir evenly to obtain a premix;

[0060] The premix is ground to a fineness of less than 10 μm by a three-roll machine to obtain a UV-LED curable pad printing ink.

[0061] Another embodiment of the present invention also provides the application of the above-mentioned UV-LED curable pad printing ink in special advertisements, automobile industry, capacitor aluminum case, computer keyboard, instrument and meter.

Embodiment 1

[0072] This embodiment is used to illustrate the UV-LED curing pad printing ink disclosed in the present invention and its preparation method, including the following steps:

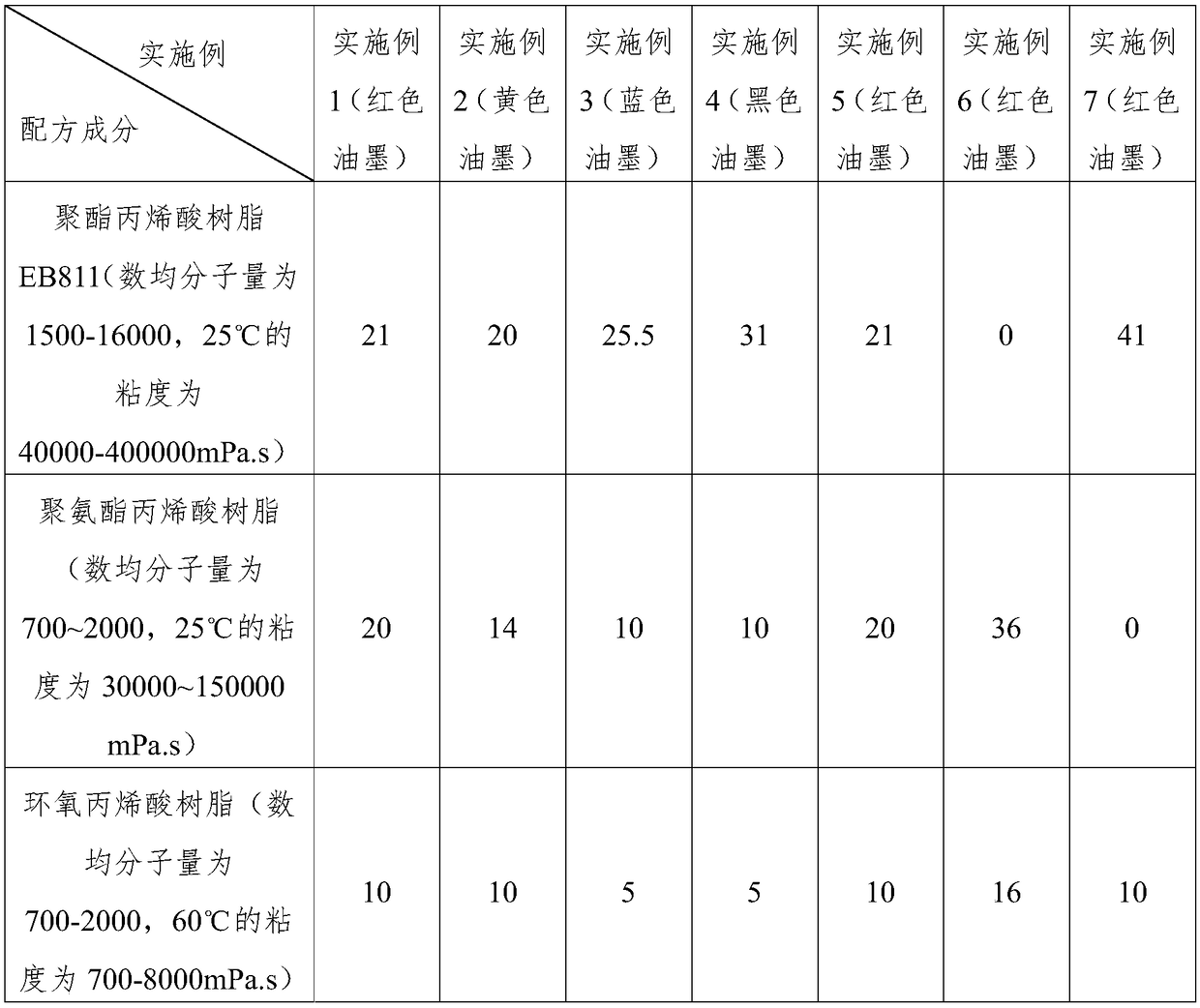

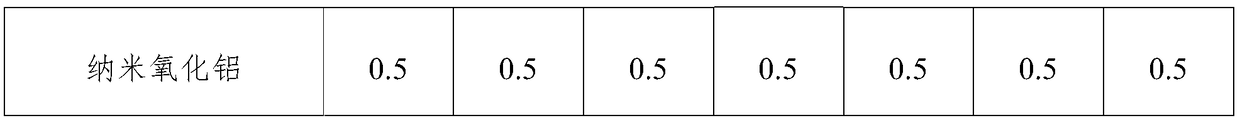

[0073] Step 1: According to the components and mass ratio listed in Example 1 in Table 1, under the mixer in the starting state of the batching kettle, add polyester acrylic resin, polyurethane acrylic resin, monomer, dispersant, and stir at 600 rpm for 10 minutes , to obtain a mixture.

[0074] Step 2: According to the components listed in Example 1 in Table 1 and the mass ratio, the adhesion promoter, photoinitiator, pigment, surface additives, and anti-scratch additives are put into the mixture, at a speed of 1000 rpm / min for 30min to obtain a premix.

[0075] Step 3: Grinding the above-mentioned premix to a fineness of less than 10um through a three-roller machine to obtain UV-LED curable pad printing ink.

Embodiment 2~7

[0077] Embodiments 2 to 7 are used to illustrate the UV-LED curing pad printing ink disclosed in the present invention and its preparation method, including most of the operating steps in Embodiment 1, the difference being:

[0078] In the step 1 and the step 2, the components and mass ratios listed in Examples 2 to 7 in Table 1 were used to prepare UV-LED curing pad printing ink.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com