Erdosteine purifying method

A purification method and technology of crude erdosteine, applied in the direction of organic chemistry, can solve the problems of long operation time, cumbersome operation, difficult industrial production, etc., and achieve the effect of simple operation and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

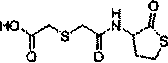

Image

Examples

Embodiment 1

[0031] In the present embodiment, the purification method of erdosteine comprises the following steps:

[0032] 1) Add 10Kg of crude erdosteine to a 200L reaction kettle, then add 100L of purified water, adjust the pH to 8.5 with 1% NaOH aqueous solution, stir and dissolve at 25±5°C, then add 20L of ethyl acetate, and stir for 10min , static layering for 20 min, liquid separation, repeat the above extraction and washing twice, liquid separation to obtain crude erdosteine aqueous solution.

[0033] 2) Adjust the pH of the crude erdosteine aqueous solution obtained above to 2.5 with hydrochloric acid, stir and crystallize at 25±5°C for 5 hours, filter, and dry to obtain 9.2Kg of fine erdosteine with a yield of 92% and a purity of HPLC 99.7%, the highest simple and impurity is 0.07%.

Embodiment 2

[0035] In the present embodiment, the purification method of erdosteine comprises the following steps:

[0036] 1) Add 10Kg of crude erdosteine to a 200L reaction kettle, then add 100L of purified water, adjust the pH to 5.0 with aqueous sodium bicarbonate solution, stir and dissolve at 25±5°C, then add 5L of isopropyl ether, and stir for 10min. Static layering for 20 min, liquid separation, repeated extraction and washing twice, liquid separation to obtain crude erdosteine aqueous solution.

[0037] 2) Adjust the pH of the crude erdosteine aqueous solution obtained above to 1.0 with phosphoric acid, stir and crystallize at 25±5°C for 5 hours, filter, and dry to obtain 8.9Kg of fine erdosteine with a yield of 89% and a purity of HPLC 99.5%, the highest single impurity is 0.05%.

Embodiment 3

[0039] In the present embodiment, the purification method of erdosteine comprises the following steps:

[0040] 1) Add 10Kg of crude erdosteine to a 200L reaction kettle, then add 100L of purified water, adjust the pH to 14 with 1% potassium hydroxide aqueous solution, stir and dissolve at 25±5°C, and then add 2000L of dichloromethane, Stirring for 10 minutes, static layering for 20 minutes, liquid separation, repeating the above extraction and washing twice, liquid separation to obtain crude erdosteine aqueous solution.

[0041] 2) Adjust the pH of the crude erdosteine aqueous solution obtained above to 6.0 with sulfuric acid, stir and crystallize at 25±5°C for 5 hours, filter, and dry to obtain 9.0Kg of fine erdosteine, with a yield of 90%, HPLC purity 99.4%, the highest single impurity is 0.08%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com