Rare earth oxide doped gadolinium zirconate powder for plasma physical vapor deposition and preparation method thereof

A technology of physical vapor deposition and rare earth oxides, which is applied in the fields of coating, molten spraying, metal material coating process, etc., can solve the influence of coating thermal cycle performance, low fracture toughness, and cannot solve the problem of strong gasification ability and flow Good properties and other problems, to achieve the effect of increased lattice distortion, strong phonon scattering ability, and improved fracture toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

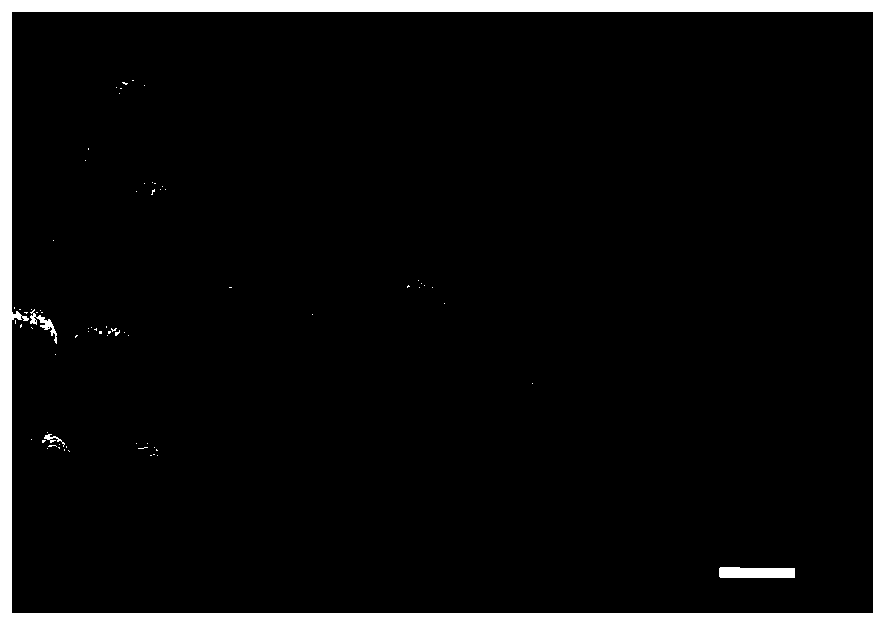

Image

Examples

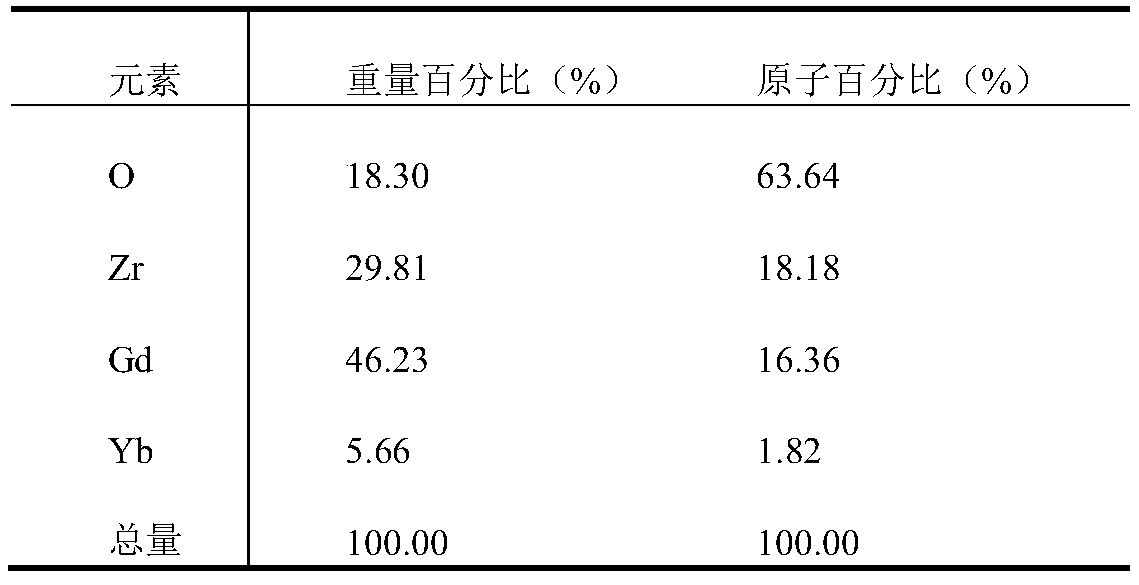

Embodiment 1

[0041] The preparation method of rare earth oxide doped gadolinium zirconate powder for plasma physical vapor deposition in this embodiment includes the following steps:

[0042] Step 1. Mix gadolinium salt, zirconium salt and ytterbium salt according to the molar ratio of Gd:Zr:Yb=0.9:1:0.1, then add deionized water and stir until the gadolinium salt, zirconium salt and ytterbium salt are completely dissolved to obtain mixture;

[0043] The total concentration of the gadolinium salt, zirconium salt and ytterbium salt in the mixed solution is 0.3 mol / L; the gadolinium salt is a water-soluble trivalent gadolinium salt, and the gadolinium salt used in this embodiment is gadolinium nitrate; The zirconium salt is a water-soluble tetravalent zirconium salt, the zirconium salt used in this embodiment is zirconium nitrate; the ytterbium salt is a water-soluble trivalent ytterbium salt, and the ytterbium salt used in this embodiment is ytterbium nitrate;

[0044] Step 2. Use ammonia water w...

Embodiment 2

[0055] The preparation method of rare earth oxide doped gadolinium zirconate powder for plasma physical vapor deposition in this embodiment includes the following steps:

[0056] Step 1. Mix the gadolinium salt, zirconium salt and scandium salt according to the molar ratio of Gd:Zr:Sc=0.9:1:0.1, then add deionized water and stir until the gadolinium salt, zirconium salt and scandium salt are completely dissolved to obtain mixture;

[0057] The sum of the concentration of gadolinium salt, zirconium salt and scandium salt in the mixed solution is 0.8 mol / L; the gadolinium salt is a water-soluble trivalent gadolinium salt, and the gadolinium salt used in this embodiment is gadolinium nitrate; The zirconium salt is a water-soluble tetravalent zirconium salt, the zirconium salt used in this embodiment is zirconium nitrate; the scandium salt is a water-soluble trivalent scandium salt, and the scandium salt used in this embodiment is scandium nitrate;

[0058] Step 2. Use ammonia water wit...

Embodiment 3

[0068] The preparation method of rare earth oxide doped gadolinium zirconate powder for plasma physical vapor deposition in this embodiment includes the following steps:

[0069] Step 1. Mix the gadolinium salt, zirconium salt and ytterbium salt according to the molar ratio of Gd:Zr:Yb=0.7:1:0.3, then add deionized water and stir until the gadolinium salt, zirconium salt and ytterbium salt are completely dissolved to obtain mixture;

[0070] The sum of the concentration of gadolinium salt, zirconium salt and ytterbium salt in the mixed solution is 0.6 mol / L; the gadolinium salt is a water-soluble trivalent gadolinium salt, and the gadolinium salt used in this embodiment is gadolinium nitrate; The zirconium salt is a water-soluble tetravalent zirconium salt, the zirconium salt used in this embodiment is zirconium nitrate; the ytterbium salt is a water-soluble trivalent ytterbium salt, and the ytterbium salt used in this embodiment is ytterbium nitrate;

[0071] Step 2. Use ammonia wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| fluidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com